Soil improvement and root inducing type enzyme carbon-based functional fertilizer for continuous cropping tobaccos and application method thereof

A method of application and technology of functional fertilizers, applied in the direction of fertilization methods, applications, organic fertilizers, etc., can solve the problems of no nutrient supply, limited soil microbial carbon source, too stable carbon activity, etc., to reduce gas emissions and improve soil physical structure , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

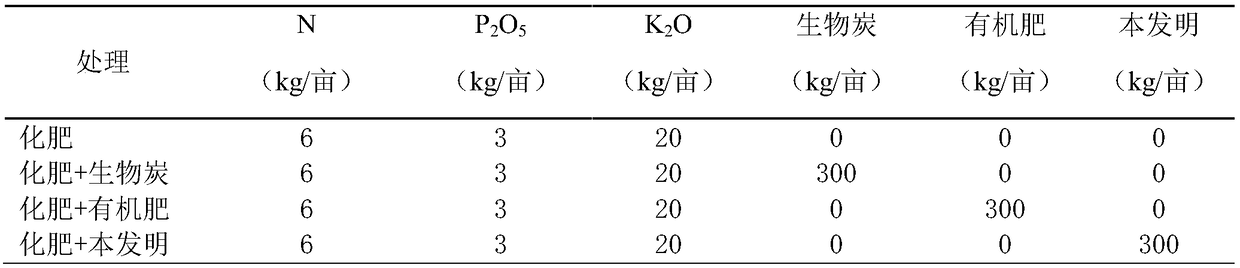

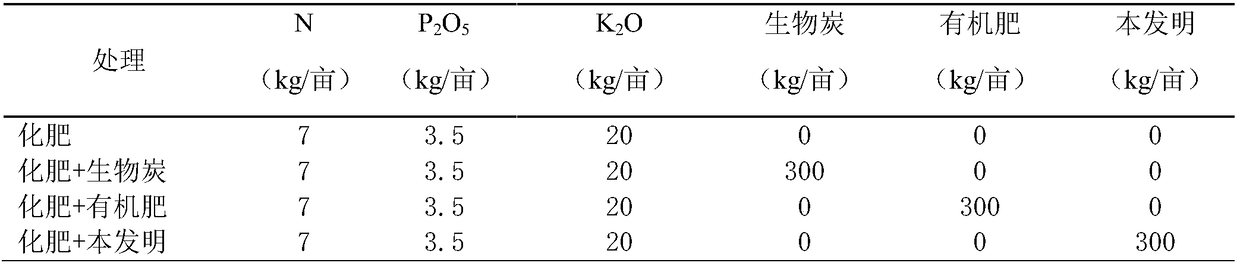

Embodiment 1

[0020] A continuous-cropping tobacco-improving soil improvement root-promoting enzyme carbon-based functional fertilizer, including 50% distiller's grain biochar, 40% decomposed clinker, 8% seaweed powder, 1% enzyme bacteria, 0.9% Bacillus amyloliquefaciens, and 0.1% sodium nitrophenolate . Fully mix distiller's grains biochar, decomposed clinker, seaweed powder, and enzyme bacteria according to the formula, adjust the water content to 60-65%, pile up and ferment for 10-15 days, and add solution after the water content of the material reaches 20-30%. Amylobacter agent, sodium nitrophenolate, mix well.

[0021] Among them, the preparation method of distiller's grain biochar is as follows: using distiller's grains obtained from mixed fermentation of sorghum, rice, glutinous rice, wheat, corn, etc. , After the product is crushed and washed with water, it passes through a 60-mesh sieve.

[0022] The preparation method of decomposed clinker is: uniformly mix 99% of rice bran and ...

Embodiment 2

[0025] A continuous-cropping tobacco soil improving enzyme carbon-based functional fertilizer, including 45% distiller's grain biochar, 43% decomposed clinker, 10% seaweed powder, 0.95% enzyme bacteria, 1% Bacillus amyloliquefaciens, and 0.05% sodium nitrophenolate . Fully mix distiller's grains biochar, decomposed clinker, seaweed powder, and enzyme bacteria according to the formula, adjust the water content to 60-65%, pile up and ferment for 10-15 days, and add solution after the water content of the material reaches 20-30%. Amylobacter agent, sodium nitrophenolate, mix well.

[0026] Among them, the preparation method of distiller's grain biochar is: using distiller's grains obtained from mixed fermentation of sorghum, rice, glutinous rice, wheat, corn, etc. , After the product is crushed and washed with water, it passes through a 60-mesh sieve.

[0027] The preparation method of decomposed clinker is: uniformly mix 99% of rice bran and 1% of decomposed agent, adjust the ...

Embodiment 3

[0030] A continuous-cropping tobacco-improving soil improvement root-promoting enzyme carbon-based functional fertilizer, including 48% distiller's grain biochar, 40% decomposed clinker, 10% seaweed powder, 1% enzyme bacteria, 0.9% Bacillus amyloliquefaciens, and 0.1% sodium nitrophenolate . Fully mix distiller's grain biochar, decomposed clinker, seaweed powder, and enzyme bacteria according to the formula amount, adjust the water content to 60-65%, pile up and ferment for 10-15 days, and add solution after the water content of the material is 20-30%. Amylobacter agent, sodium nitrophenolate, mix well.

[0031]Among them, the preparation method of distiller's grain biochar is as follows: using distiller's grains obtained from mixed fermentation of sorghum, rice, glutinous rice, wheat, corn, etc. , After the product is crushed and washed with water, it passes through a 60-mesh sieve.

[0032] The preparation method of decomposed clinker is: uniformly mix 99% of rice bran and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com