Special material for new-energy battery shell and preparation method thereof

A battery casing and new energy technology, applied in the field of special materials for new energy battery casings and their preparation, can solve the problems of insecurity, application restrictions, serious melting droplets, etc., and achieve high melting index, good fluidity, and easy processing and molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

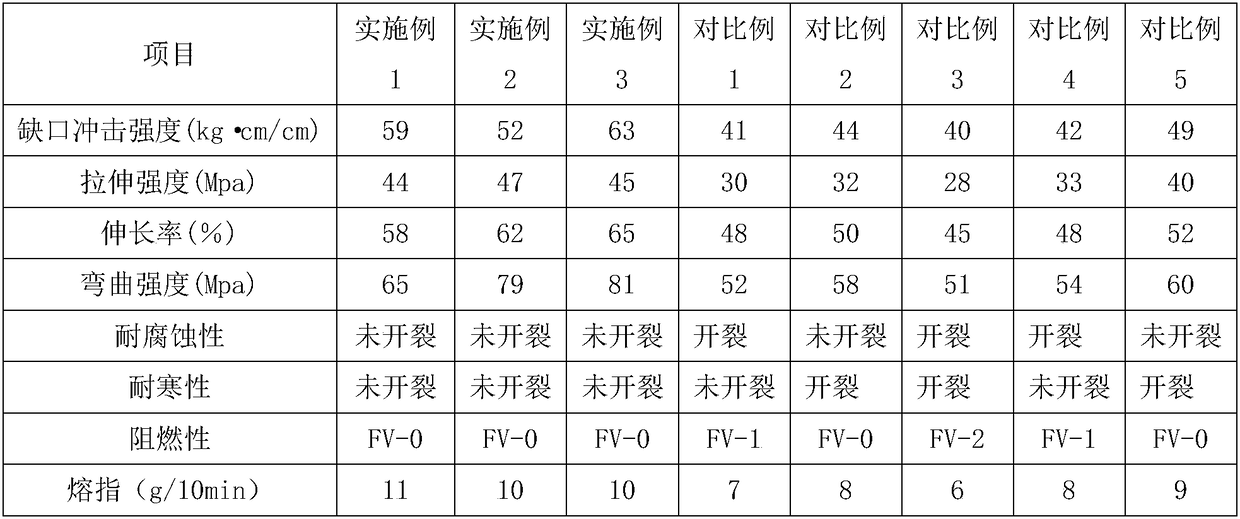

Examples

Embodiment 1

[0024] A special material for a new energy battery casing, comprising the following raw materials in parts by weight: 100 parts of polypropylene, 5 parts of niobium pentoxide, 6 parts of sodium tetrachloropalladium, 8 parts of modified chabazite powder, and 8 parts of modified lignin , 2 parts of xylitol;

[0025] The preparation method of the modified chabazite powder is as follows: crush the chabazite and sieve it with a 60-mesh sieve, wash it with water, and dry it to obtain a pretreated chabazite; use absolute ethanol and γ-(2,3-epoxypropylene Oxygen) propyltrimethoxysilane carries out epoxidation to pretreatment chabazite; Then add 200 parts of deionized water and 20 parts of lauryl amidopropyl betaine in reactor, stir; Carry out ultrasonic treatment 5min afterwards; Solid-liquid separation is carried out, and the separated solid is washed with deionized water until the filtrate becomes neutral; the solid is dried to obtain the modified chabazite powder.

[0026] The pre...

Embodiment 2

[0029] A special material for a new energy battery casing, comprising the following raw materials in parts by weight: 135 parts of polypropylene, 12 parts of niobium pentoxide, 15 parts of sodium tetrachloropalladium, 14 parts of modified chabazite powder, and 12 parts of modified lignin , 6 parts of xylitol;

[0030] The preparation method of the modified chabazite powder is as follows: crush the chabazite and sieve it with an 80-mesh sieve, wash with water, and dry to obtain a pretreated chabazite; use absolute ethanol and γ-(2,3-epoxypropylene Oxygen) propyltrimethoxysilane carries out epoxidation to pretreatment chabazite; Then add 300 parts of deionized water and 30 parts of lauryl amidopropyl betaine in reactor, stir; Carry out ultrasonic treatment 10min afterwards; Solid-liquid separation is carried out, and the separated solid is washed with deionized water until the filtrate becomes neutral; the solid is dried to obtain the modified chabazite powder.

[0031] The pre...

Embodiment 3

[0034] A special material for a new energy battery casing, comprising the following raw materials in parts by weight: 122 parts of polypropylene, 8 parts of niobium pentoxide, 10 parts of sodium tetrachloropalladium, 11 parts of modified chabazite powder, and 10 parts of modified lignin , 4 parts of xylitol.

[0035] The preparation method of the modified chabazite powder is as follows: crush the chabazite and sieve it with a 70-mesh sieve, wash it with water, and dry it to obtain a pretreated chabazite; use absolute ethanol and γ-(2,3-epoxypropylene Oxygen) propyltrimethoxysilane carries out epoxidation to pretreatment chabazite; Then in reactor, add 260 parts of deionized water and 25 parts of lauryl amidopropyl betaines, stir; Carry out ultrasonic treatment 7min afterwards; Solid-liquid separation is carried out, and the separated solid is washed with deionized water until the filtrate becomes neutral; the solid is dried to obtain the modified chabazite powder.

[0036] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com