TPE trundle material with high resilience and high wear resistance and preparation method

A technology with high wear resistance and high resilience, applied in the field of caster materials and preparation, can solve the problems of poor compatibility, complex process, difficult coating, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of high resilience and high wear resistance TPE caster material, comprising the following steps:

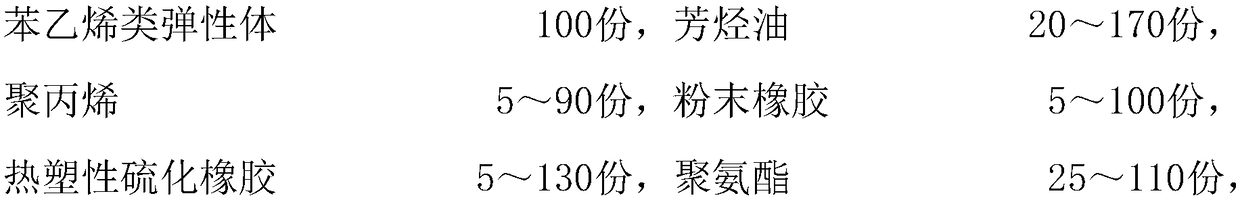

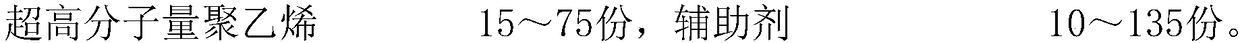

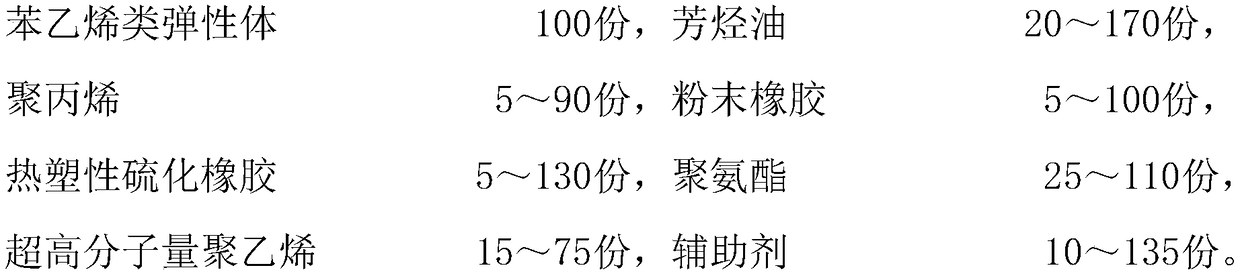

[0031] a. Weigh styrene-based elastomer, aromatic oil, polypropylene, powdered rubber, thermoplastic vulcanized rubber, polyurethane, ultra-high molecular weight polyethylene, auxiliary agent, and spare according to parts by mass.

[0032] b. Add the weighed styrene-based elastomer into the high-mixer, spray the aromatic oil over the high-mixer to the surface of the styrene-based elastomer through a sprayer, and stir while spraying, so that the aromatic oil is uniformly and fully Styrene elastomer absorption;

[0033] c. Add the weighed polypropylene, powdered rubber, thermoplastic vulcanizate, polyurethane, ultra-high molecular weight polyethylene, and auxiliary agents into the mixer in sequence and mix and stir at a high speed of 400r / min for 2 to 10 minutes until they are evenly stirred to obtain a mixture. During the stirring process, the temperat...

Embodiment 1

[0036] The caster material is composed of the following components by mass: 100 parts of styrene-based elastomer, 90 parts of aromatic oil, 40 parts of polypropylene, 50 parts of powdered rubber, 60 parts of thermoplastic vulcanized rubber, 50 parts of polyurethane, and 30 parts of ultra-high molecular weight polyethylene 45 parts, 45 parts of compatibilizer, 11 parts of anti-wear agent, 5 parts of lubricant, 4 parts of antioxidant.

[0037] The final obtained caster material is measured by experiments: the hardness is 72 Shore A, the elongation at break is 576%, the tensile strength is 9.5MPa, the permanent compression deformation is 59.3%, the rebound rate is 93.8%, and the walking time is 180min .

Embodiment 2

[0039] The caster material is composed of the following components in parts by mass: 100 parts of styrene-based elastomer, 20 parts of aromatic oil, 5 parts of polypropylene, 5 parts of powdered rubber, 5 parts of thermoplastic vulcanized rubber, 25 parts of polyurethane, and 15 parts of ultra-high molecular weight polyethylene 1 part, 5 parts of compatibilizer, 1 part of lubricant, 1 part of antioxidant.

[0040]The final obtained caster material is measured by experiments: the hardness is 64 Shore A, the elongation at break is 555%, the tensile strength is 7.0MPa, the permanent compression deformation is 49.2%, the rebound rate is 92.4%, and the wear-resistant walking time It is 159min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com