Poly(glycerolsebacate) 3D printing nano generator and preparation method and application thereof

A technology of glycerol sebacate and nanogenerator, applied in the direction of additive processing, can solve the problems of slowing down non-degradability, weakening environmental friendliness, etc., to simplify the preparation process, promote further development, good elasticity and conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Materials

[0038] Polyglyceryl sebacate (PGS) is formed by the polycondensation of glycerol (99.5%, Sigma-Aldrich) and sebacic acid (99%, Sigma-Aldrich). Salt pellets were purchased from Shanghai Chemical Reagent Factory, China. Carbon nanotubes (CNTs) were purchased from Bailingwei Technology Co., Ltd. (99.9%, inner diameter: 5-10 nm, outer diameter: 10-20 nm, length: 10-30 μm).

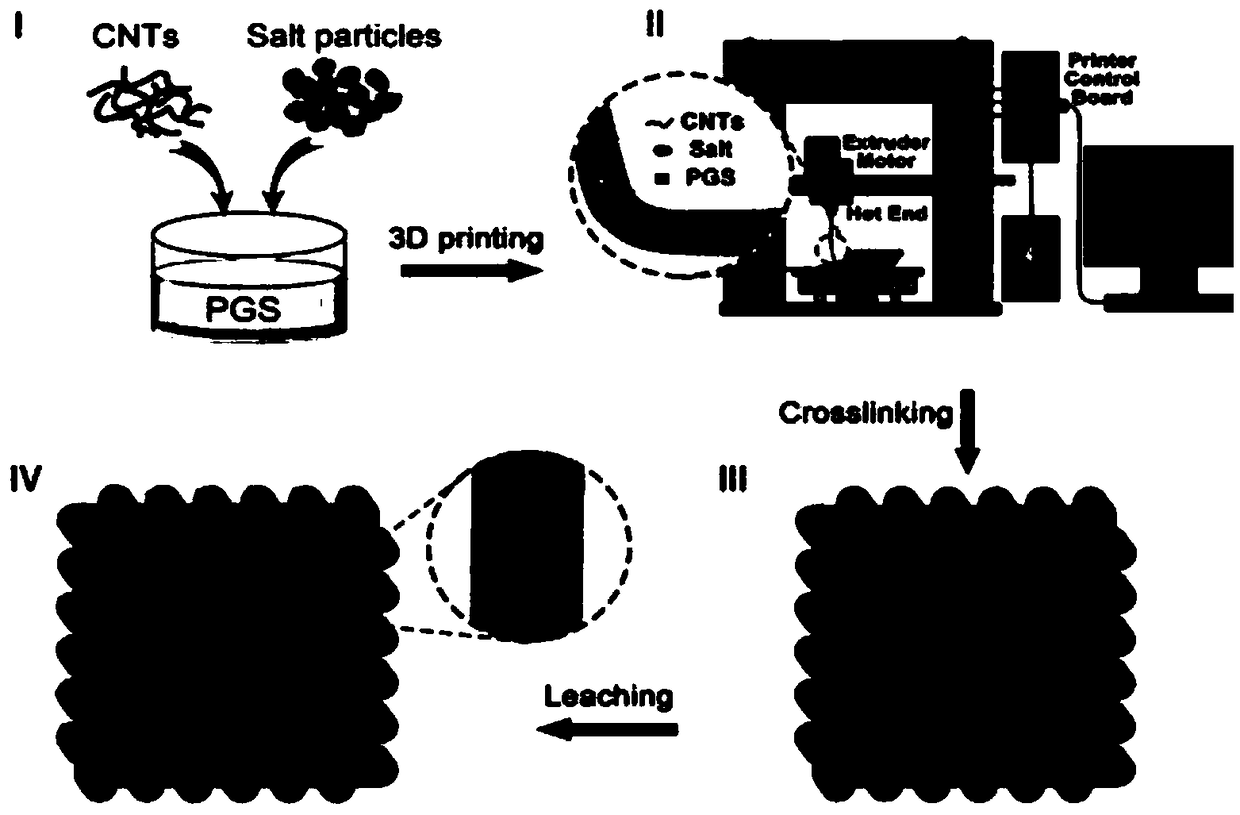

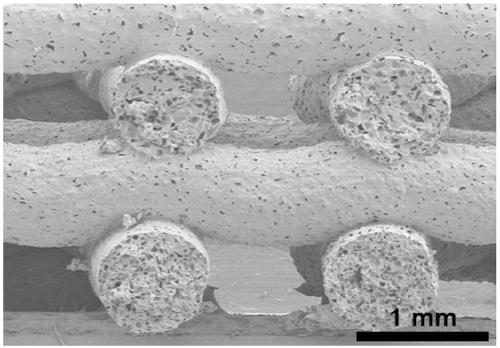

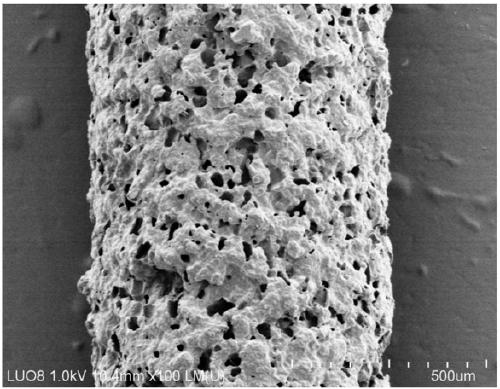

[0039] 2. Preparation of Composite Samples

[0040]①Sebacic acid recrystallization. First, take sebacic acid in a three-necked bottle, set up the device, heat in a water bath at 78-80°C, then add ether until the sebacic acid is dissolved, take out the solution after the sebacic acid is completely dissolved, cool to room temperature, and filter with suction. The above process was repeated three times, and the sebacic acid obtained by the last suction filtration was poured into an evaporating dish (pad aluminum foil), covered with aluminum foil (perforated), and vacuum-dried at 60°C to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com