Cleaning agent for cleaning hollow glass

A glass cleaning and cleaning agent technology, applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve glass damage, impurity can not be well removed, processing, packaging, sales, use effects and other problems to achieve a good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

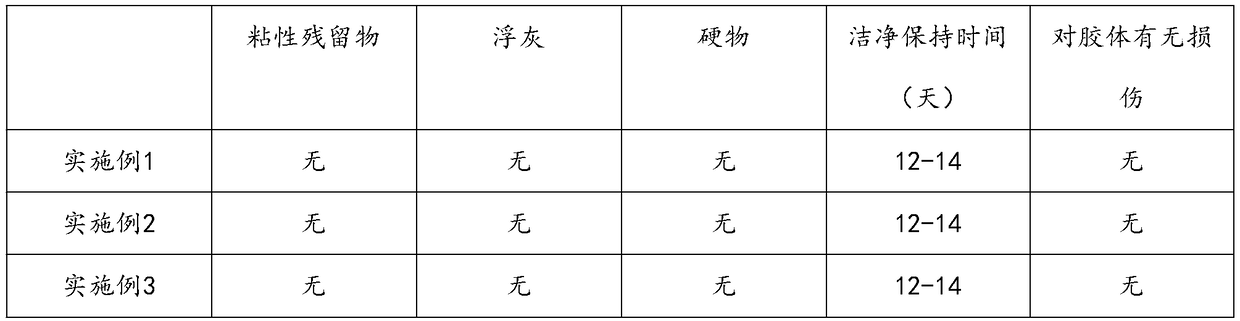

Examples

Embodiment 1

[0032] A cleaning agent for hollow glass cleaning, characterized in that: it is made of the following materials by weight,

[0033] 4 parts of tall oil amphopropionate sodium, 4 parts of lauryl hydroxy sultaine, 1 part of fatty alcohol polyoxyethylene hydrocarbon ether salt, 1 part of absolute ethanol, N, N-dimethyldecyl- 2 parts of N-amine oxide, 1 part of allantoin, 1 part of linear alkylbenzene sulfonate, 1 part of menthol, 2 parts of castor oil polyoxyethylene ether, 5 parts of blending agent, 30 parts of deionized water;

[0034] The preparation method comprises the following steps,

[0035] Ⅰ Add deionized water into the pot, then add the above-mentioned materials in turn, and stir while adding;

[0036] Ⅱ After stirring for 20-24 minutes, apply ultrasonic treatment;

[0037] Ⅲ Stir at 55-65°C for 16-21 minutes after ultrasonic treatment, then cool to 18-22°C;

[0038] The time interval for adding the materials in I is 2-4 minutes;

[0039] The speed of stirring in t...

Embodiment 2

[0050] A cleaning agent for hollow glass cleaning, characterized in that: it is made of the following materials by weight,

[0051] 8 parts of tall oil amphopropionate sodium, 8 parts of lauryl hydroxy sultaine, 4 parts of fatty alcohol polyoxyethylene hydrocarbon ether salt, 4 parts of absolute ethanol, N, N-dimethyldecyl- 6 parts of N-amine oxide, 3 parts of allantoin, 4 parts of linear alkylbenzene sulfonate, 2 parts of menthol, 5 parts of castor oil polyoxyethylene ether, 9 parts of blending agent, 35 parts of deionized water;

[0052] The preparation method comprises the following steps,

[0053] Ⅰ Add deionized water into the pot, then add the above-mentioned materials in turn, and stir while adding;

[0054] Ⅱ After stirring for 20-24 minutes, apply ultrasonic treatment;

[0055] Ⅲ Stir at 55-65°C for 16-21 minutes after ultrasonic treatment, then cool to 18-22°C;

[0056] The time interval for adding the materials in I is 2-4 minutes;

[0057] The speed of stirring...

Embodiment 3

[0068] A cleaning agent for hollow glass cleaning, characterized in that: it is made of the following materials by weight,

[0069] 6 parts of tall oil amphopropionate sodium, 7 parts of lauryl hydroxy sultaine, 3 parts of fatty alcohol polyoxyethylene hydrocarbon ether salt, 2 parts of absolute ethanol, N, N-dimethyldecyl- 5 parts of N-amine oxide, 2 parts of allantoin, 3 parts of linear alkylbenzene sulfonate, 1 part of menthol, 4 parts of castor oil polyoxyethylene ether, 8 parts of blending agent, 33 parts of deionized water;

[0070] The preparation method comprises the following steps,

[0071] Ⅰ Add deionized water into the pot, then add the above-mentioned materials in turn, and stir while adding;

[0072] Ⅱ After stirring for 20-24 minutes, apply ultrasonic treatment;

[0073] Ⅲ Stir at 55-65°C for 16-21 minutes after ultrasonic treatment, then cool to 18-22°C;

[0074] The time interval for adding the materials in I is 2-4 minutes;

[0075] The speed of stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com