Impact decomposition device for thermobaric fuel

A fuel, temperature and pressure technology, applied in the direction of measuring devices, analysis materials, fuel oil testing, etc., can solve the problems of large differences in the distribution of fuel detonation temperature field and pressure field, poor fuel decomposition effect, and small impact pressure of shock tube , to achieve the effect of realizing decomposition reaction test, realizing high-efficiency utilization, and eliminating fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

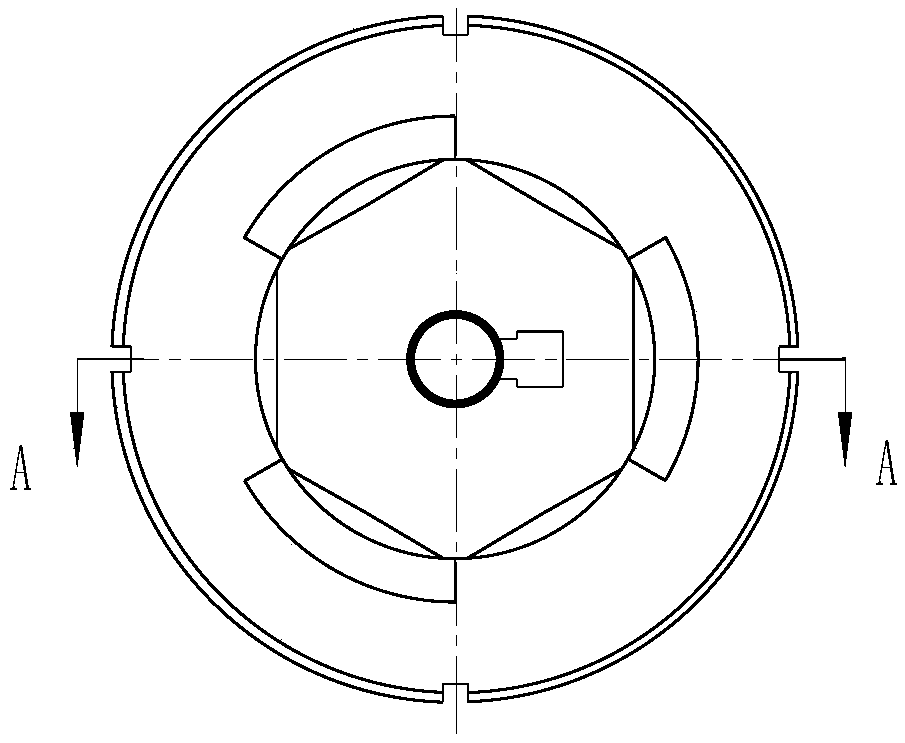

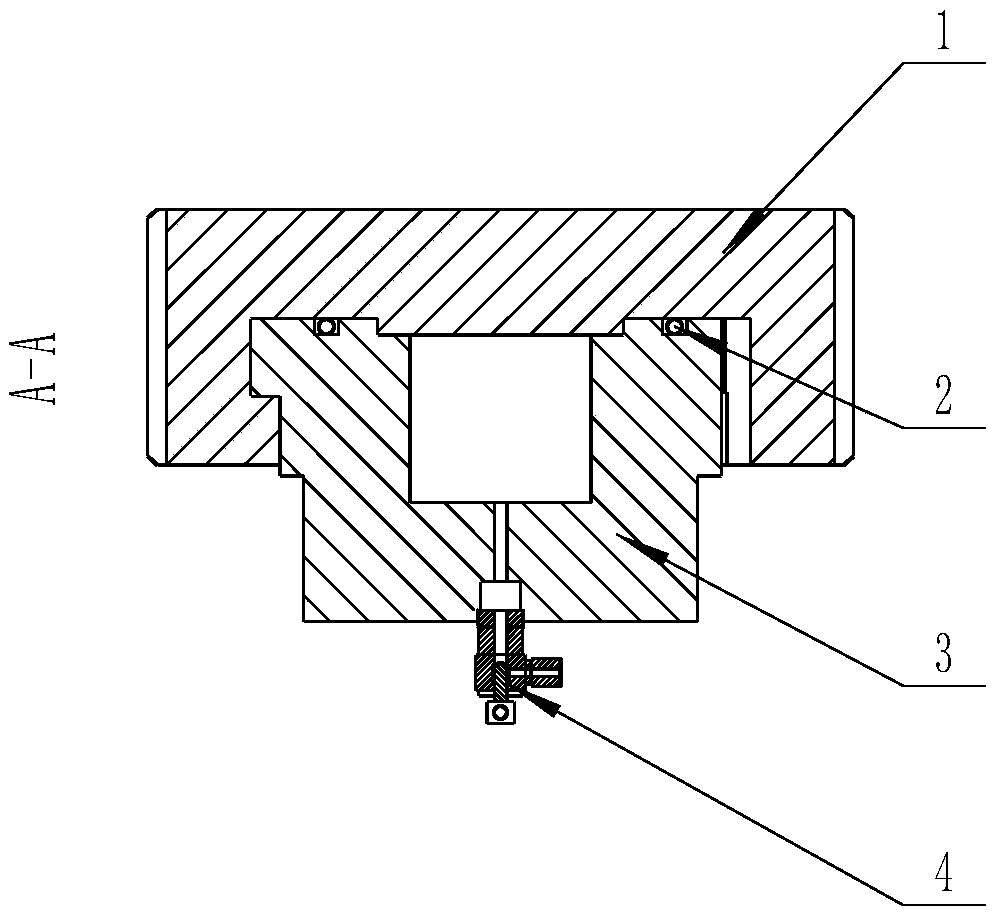

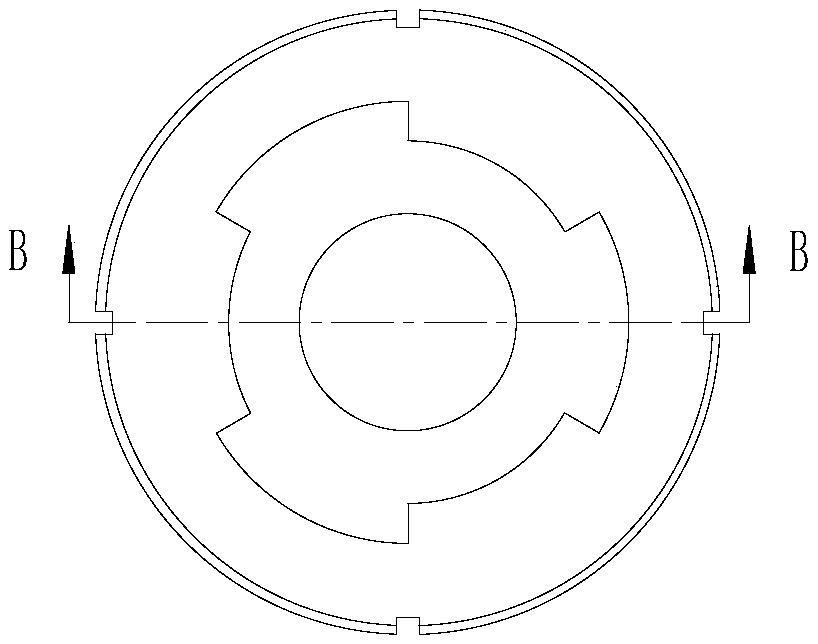

[0025] refer to Figure 1 to Figure 5 , this embodiment gives a specific structure and manufacturing and assembly examples of a warm-pressurized fuel shock decomposition device. The thermal-pressure fuel shock decomposition device at least includes an explosion upper cover 1 , a sealing ring 2 , a fuel container 3 and a gas valve 4 .

[0026] refer to image 3 and Figure 4 , Explosion upper cover 1 is integrally formed with a cylindrical aluminum alloy cavity, with an outer diameter of 180mm, an inner diameter of 120mm, a height of 66mm, a top thickness of 25mm, the upper and lower end surfaces are horizontal, and the transition between the upper and lower end surfaces and the outer surface is a 45° chamfer. , the outer surface is evenly distributed with 4 limit grooves that run through up and down, the groove width is 14mm, and the depth is 6mm. The inner top of the concave cavity is a protruding circular platform with a diameter of 60mm and a height of 4mm. On the inner...

Embodiment 2

[0030] This example gives an example of impact decomposition of powdered ditetraethylammonium dodecahydrododecaborate using the warm-pressure fuel impact decomposition device prepared in Example 1.

[0031] The test dose is 50g, and the packing density is 0.995g / cm 3 . The main explosive is pure TNT powder column with a density of 1.5g / cm 3 , diameter 40mm, dosage 50g. The detonator is used to detonate directly, and the decomposed gas products are collected in the gas collection bag through the gas valve and detected by gas chromatography. The detected gas components include H 2 、CH 4 NH 3 , The solid residue is mainly unreacted fuel, elemental boron and a small amount of carbon black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com