Multi-core optical fiber coupler and preparation method thereof

A multi-core fiber and coupler technology, which is applied in the coupling of optical waveguides, instruments, light guides, etc., can solve the problem that the cost and performance of multi-core fiber couplers are difficult to achieve, and achieves low processing difficulty, convenient fusion and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the multi-core optical fiber coupler provided by the invention comprises the following steps:

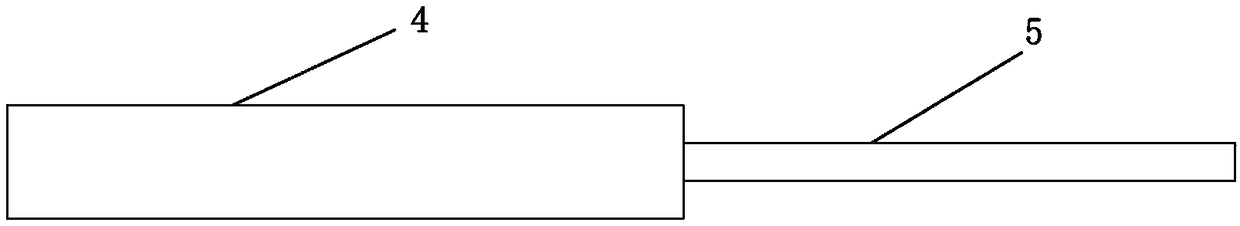

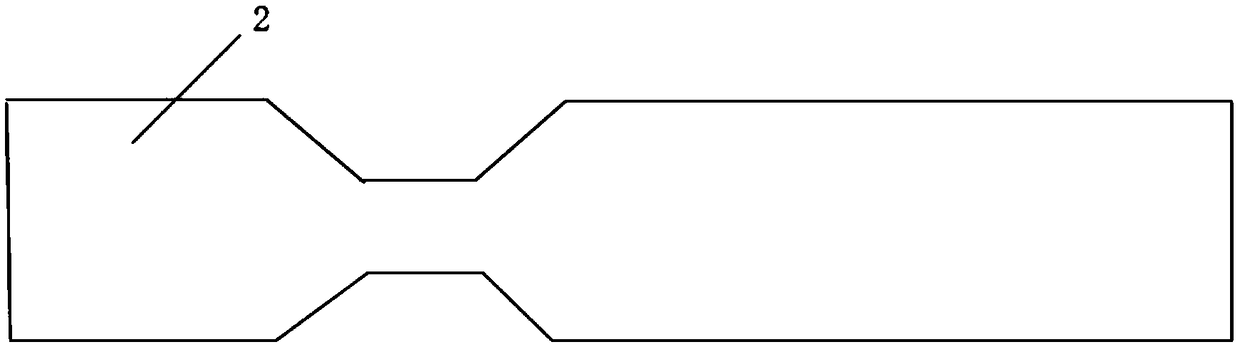

[0041] (1) After stripping off part of the coating layer on the surface of N single-mode optical fibers, N first intermediate pieces are obtained; the first intermediate piece is divided into two parts, one part is an optical fiber comprising only a core layer and a cladding layer, and the other part It is a complete optical fiber including core, cladding and coating. Preferably, the coating layer of N single-mode optical fibers is stripped, and then the first intermediate piece is obtained after dedusting with a dust-free paper dipped in alcohol; the first intermediate piece is divided into two parts, and the front part is composed of a core layer and a cladding Layered optical fiber, the length is 4 to 6 cm, the rear end part is a complete optical fiber including the core layer, cladding and coating layer, the length is 1.5 to 3 meters, and N is an...

Embodiment 2

[0063] Embodiment 2 provides a kind of preferred preparation method of the multi-core optical fiber coupler based on the low-melting point sleeve, the circular sleeve adopted in step (2), one end of which can be made into a bell mouth to facilitate the insertion of the optical fiber without damaging the single-mode Optical fiber coating.

Embodiment 3

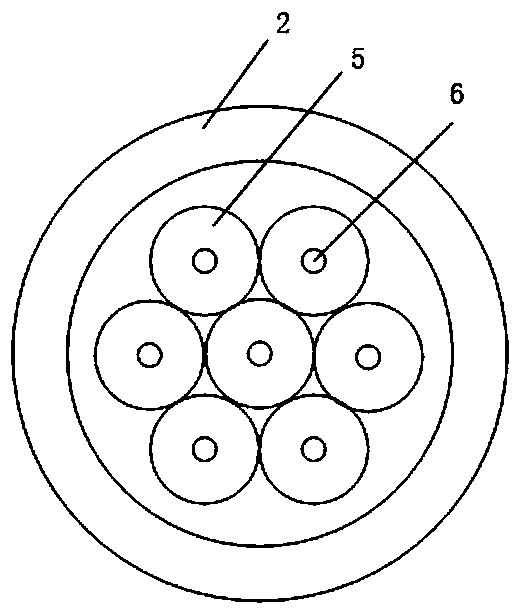

[0064] Embodiment 3 provides a kind of preferred preparation method of the multi-core fiber coupler based on the low-melting point sleeve, the circular sleeve adopted in step (2), is the same cylinder as the geometric distribution of the multi-core optical fiber core casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com