Alignment film orientation method, alignment film substrate and display panel

An alignment film and orientation technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of residual fluff, strict light source requirements, and narrow viewing angle of liquid crystal display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

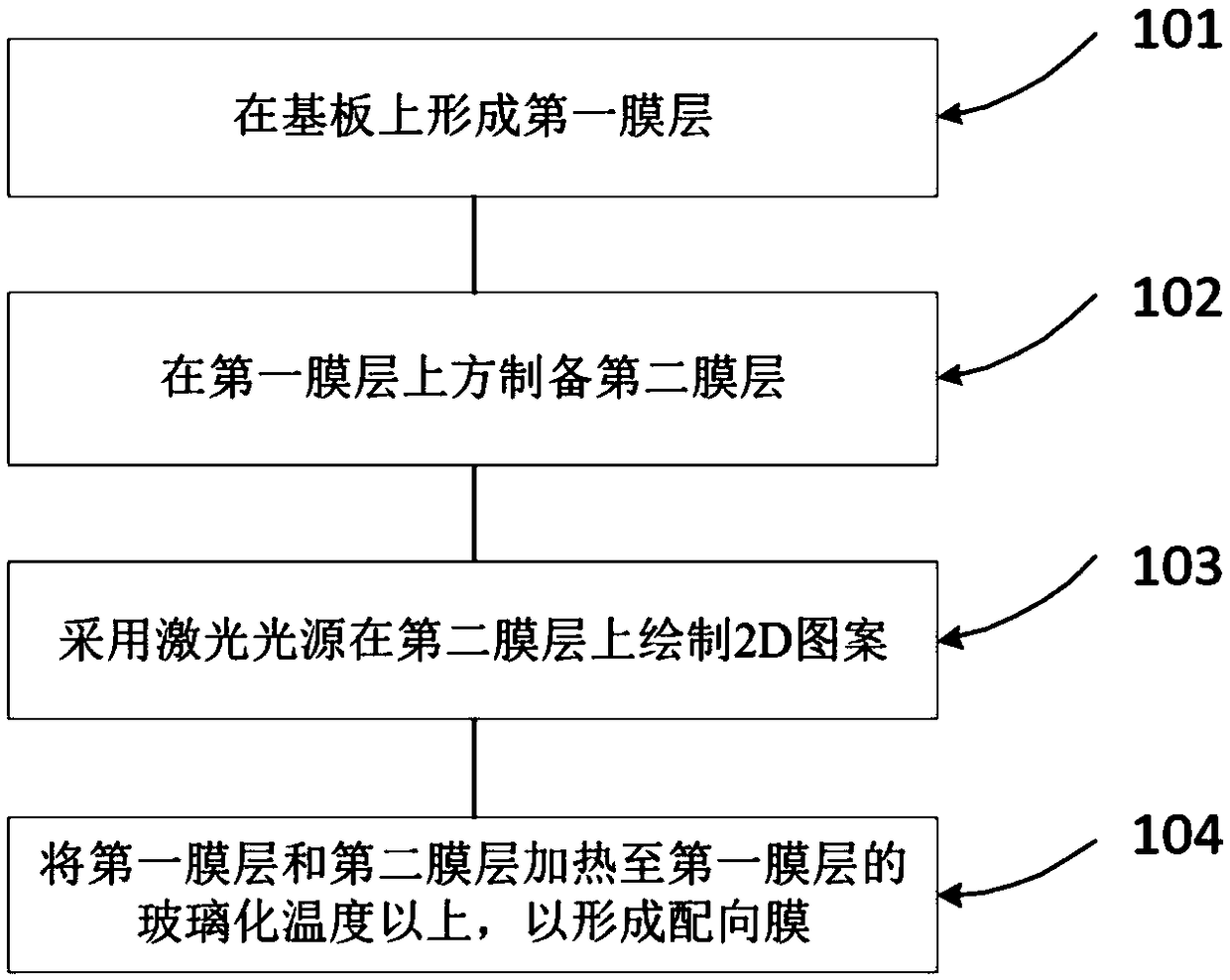

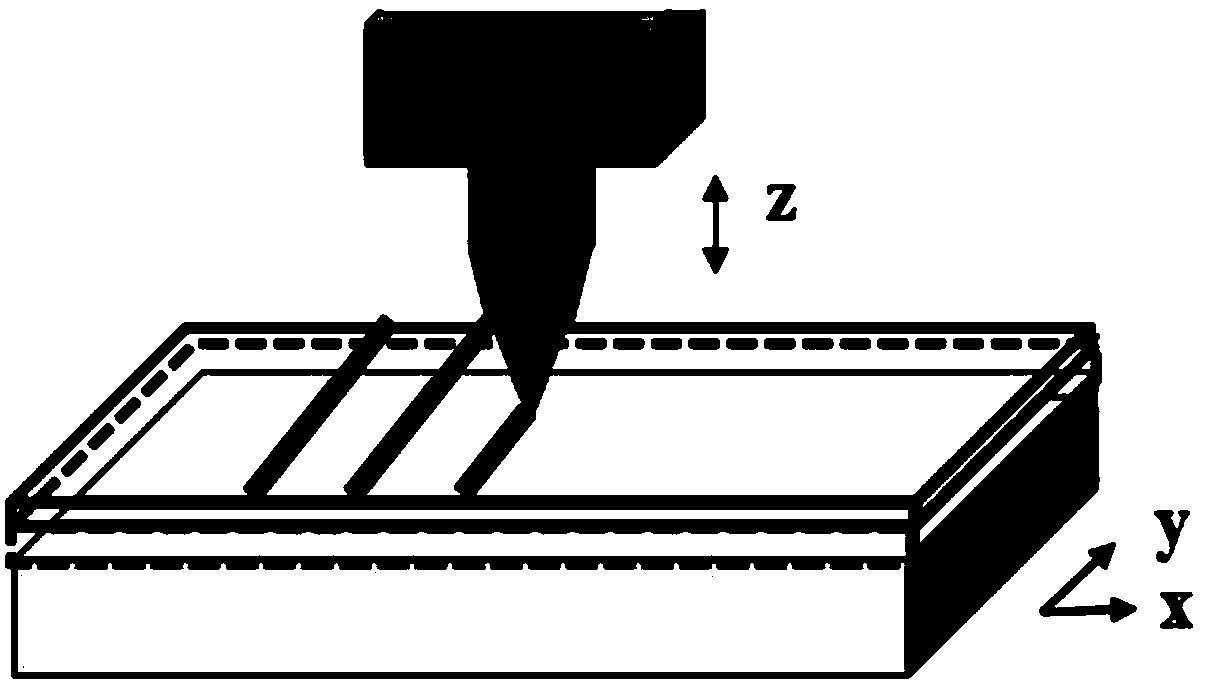

[0022] figure 1 The alignment method for the alignment film provided in Embodiment 1 of the present invention, such as figure 1 As shown, the alignment film orientation method includes the following steps:

[0023] S101, forming a first film layer on the substrate;

[0024] For example, the first film layer solution can be coated on the substrate, and then annealed and solidified to form the first film layer. Annealing acts to evaporate the solvent and solidify the film. The substrate can be selected from glass, silicon wafer or plastic, mainly depending on the use requirements. The plastic substrate can be bent to adapt to flexible development solutions. It should be noted that if a plastic substrate is used, the glass transition temperature of the plastic should be higher than the glass transition temperature of the first film layer, so as to avoid the vitrification change of the substrate caused by heating and affect the accumulated stress of the first film layer. The f...

Embodiment 2

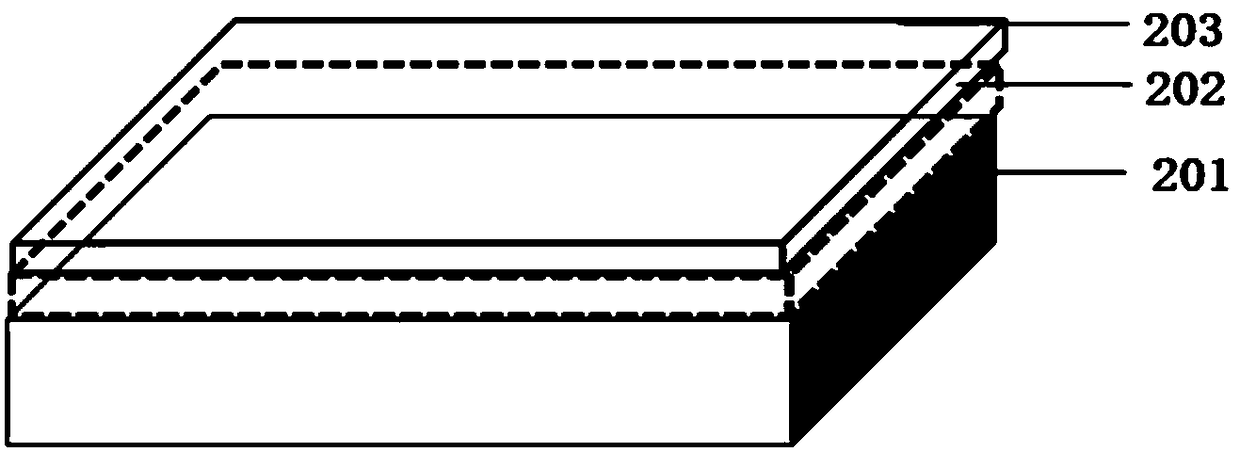

[0037] An embodiment of the present invention provides an alignment film substrate, which is prepared by using the alignment film orientation method in Embodiment 1.

[0038] The alignment film substrate provided by the embodiment of the present invention adopts a double-layer film structure and is manufactured by a non-contact patterning method, which realizes any patterned orientation of liquid crystals and avoids related problems caused by contact friction. By optimizing the process parameters , can realize the fabrication of the alignment film substrate with nanoscale wrinkle period.

Embodiment 3

[0040] An embodiment of the present invention provides a display panel, which includes the alignment film substrate in the second embodiment.

[0041] Compared with the traditional display panel, the display panel in the embodiment of the present invention has a larger viewing angle, which greatly improves the user's visual experience. At the same time, the alignment film substrate of the display panel is made in a non-contact manner, which avoids the possible existence of contact friction. The problem of destroying the transistor on the lower side of the matching film substrate and remaining fluff and shavings that affect the display effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com