An insulated gate bipolar transistor and a manufacturing method thereof

A bipolar transistor and insulated gate technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problem that the breakdown voltage of the device cannot be guaranteed at the same time. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

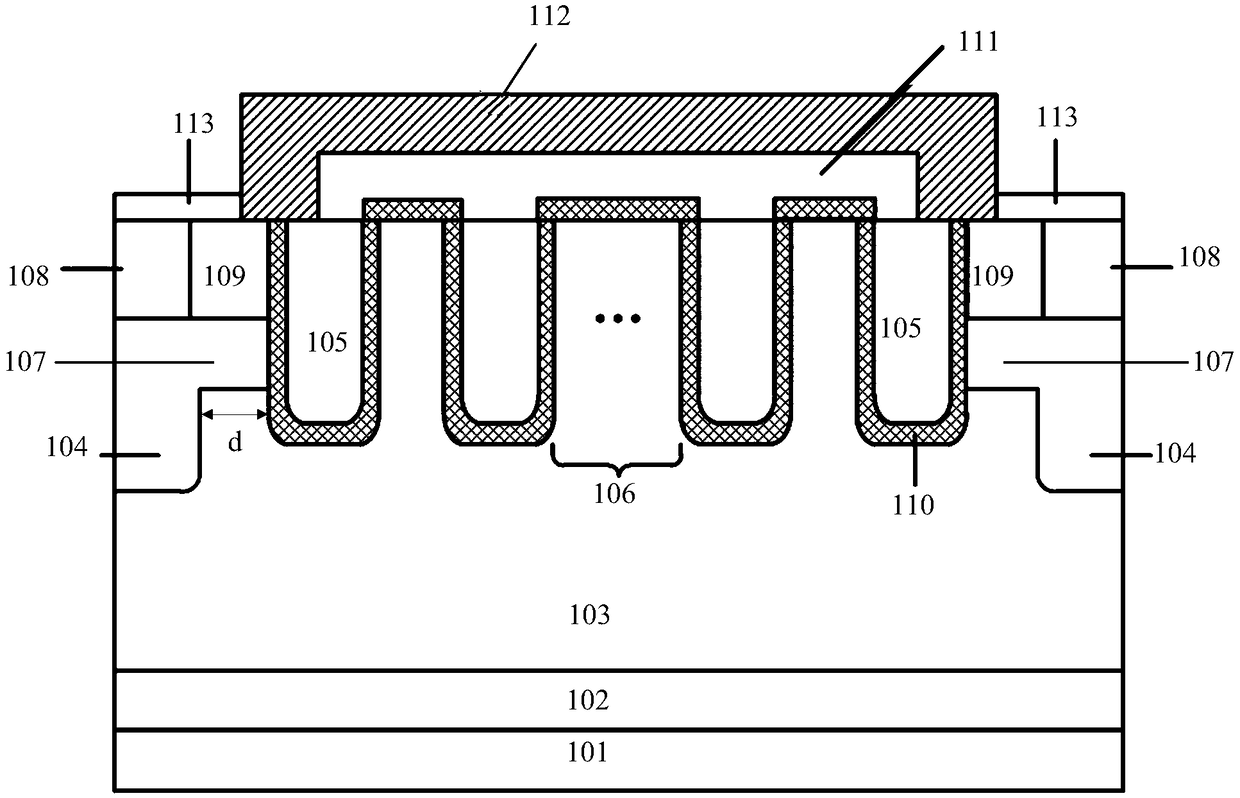

[0046] This embodiment provides an insulated gate bipolar transistor, such as figure 1 As shown, the insulated gate bipolar transistor includes: a substrate 101; a buffer layer 102, an epitaxial layer 103, a buried base region Base region 104, a trench gate 105, and a dummy region 106; wherein,

[0047] The substrate 101 is a SiC substrate of the first heavily doped type. The first heavily doped type may be N-type or P-type. The substrate 101 in this embodiment may be an N-type SiC substrate or a P-type. SiC substrate with a doping concentration of 10 18 ~10 19 cm -3 .

[0048] The buffer layer 102 is a second doping type SiC buffer layer, which is epitaxially formed on the substrate 101; the second doping type can be P-type or N-type, and the buffer layer 102 in this embodiment is a P-type SiC buffer Floor. The doping level and thickness of the buffer layer 102 can be specifically set according to the breakdown voltage, forward conduction voltage drop and dynamic characteristics ...

Embodiment 2

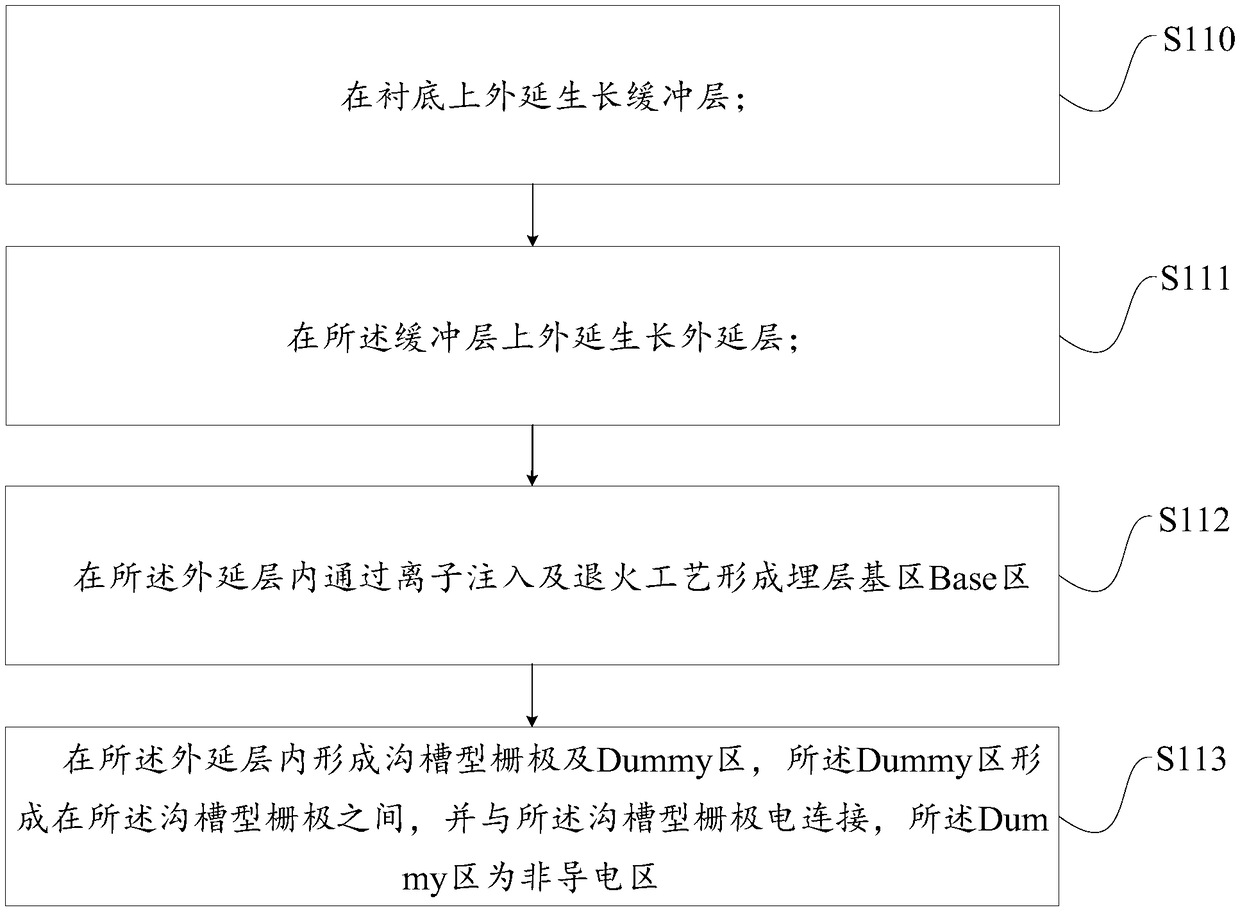

[0065] This embodiment provides a method for manufacturing an insulated gate bipolar transistor, such as figure 2 As shown, the method includes:

[0066] S110, epitaxially grow a buffer layer on the substrate;

[0067] The substrate in this embodiment is a first heavily doped SiC substrate, the first heavily doped type may be N-type or P-type, and the substrate in this embodiment may be an N-type SiC substrate or P-type SiC substrate with a doping concentration of 10 18 ~10 19 cm -3 .

[0068] The buffer layer is a SiC buffer layer of the second doping type, which is epitaxially formed on the substrate; the second doping type may be P-type or N-type, and the buffer layer in this embodiment is a P-type SiC buffer layer. The doping level and thickness of the buffer layer can be specifically set according to the breakdown voltage, forward voltage drop and dynamic characteristics of the transistor device. Dynamic characteristics refer to transistor switching characteristics and capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com