A method for preparing a lead-carbon composite material by iterative calendering

A composite material and calendering technology, applied in electrode rolling/calendering, electrode manufacturing, lead-acid batteries, etc., can solve problems such as the inability to give full play to the advantages of high carbon conductivity and large capacitance, and achieve large-scale production in batches and improve negative electrodes. The effect of easy control of life and reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

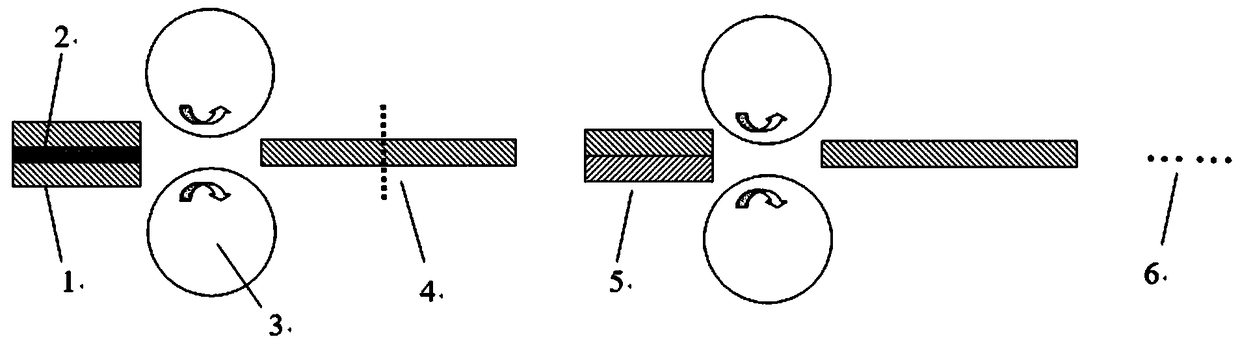

Image

Examples

Embodiment 1

[0026] A method for preparing lead-carbon composite material by iterative rolling includes the following steps:

[0027] 1) Preparation of carbon solution: Add 2 grams of graphite to absolute ethanol, and then place it in an ultrasonic cleaner at 50°C, with an ultrasonic frequency of 80 Hz, and ultrasonic treatment for 50 minutes to obtain a uniformly dispersed carbon solution;

[0028] 2) Pretreatment of the lead plate surface: the lead plate surface is pretreated by degreasing treatment, grinding treatment and acid solution cleaning in sequence; the specific steps of the degreasing treatment are: putting the lead plate into the degreasing agent at 40℃ Soak for 20 minutes, then wash off the residual solution on the surface with deionized water; among them, the degreaser is tetrasodium solution, and its composition is: 20g / L NaOH, 20g / L Na 3 PO 4 , 10g / L Na 2 CO 3 , 4g / L Na 4 SiO 4 . The specific steps of acid solution cleaning are as follows: the acid solution soaks the lead plate...

Embodiment 2

[0034] A method for preparing lead-carbon composite material by iterative rolling includes the following steps:

[0035] 1) Preparation of carbon solution: add 0.5 g of graphene to acetone, and then place it in an ultrasonic cleaner at 50°C with an ultrasonic frequency of 80 Hz and ultrasonic treatment for 50 minutes to obtain a uniformly dispersed carbon solution;

[0036] 2) Pretreatment of the lead plate surface: the lead plate surface is pretreated by degreasing treatment, polishing treatment and acid solution cleaning in sequence; the specific steps of the degreasing treatment are: putting the lead plate into the degreasing agent at 60℃ Soak for 10 minutes, then wash off the residual solution on the surface with deionized water; among them, the degreaser is a tetrasodium solution, and its composition is: 20g / L NaOH, 20g / L Na 3 PO 4 , 10g / L Na 2 CO 3 , 4g / L Na 4 SiO 4 . The specific steps of acid solution cleaning are as follows: the acid solution soaks the lead plate with a sm...

Embodiment 3

[0042] A method for preparing lead-carbon composite material by iterative rolling includes the following steps:

[0043] 1) Preparation of carbon solution: 33mg of carbon black was added to DMF, and then placed in an ultrasonic cleaner at 50°C, the ultrasonic frequency was 80 Hz, and ultrasonic treatment was performed for 50 minutes to obtain a uniformly dispersed carbon solution;

[0044] 2) Pretreatment of the lead plate surface: the lead plate surface is pretreated by degreasing treatment, grinding treatment and acid solution cleaning in sequence; the specific steps of the degreasing treatment are: putting the lead plate into the degreasing agent at 40℃ Soak for 20 minutes, then wash off the residual solution on the surface with deionized water; among them, the degreaser is tetrasodium solution, and its composition is: 20g / L NaOH, 20g / L Na 3 PO 4 , 10g / L Na 2 CO 3 , 4g / L Na 4 SiO 4 . The specific steps of acid solution cleaning are as follows: the acid solution soaks the lead pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com