A kind of preparation method of lead-carbon composite material

A composite material, lead-carbon technology, used in electrode manufacturing, lead-acid batteries, electrode rolling/calendering, etc., can solve the problem of not being able to give full play to the advantages of carbon's high conductivity and large capacitance, and achieve mass production. The effect of negative electrode life and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

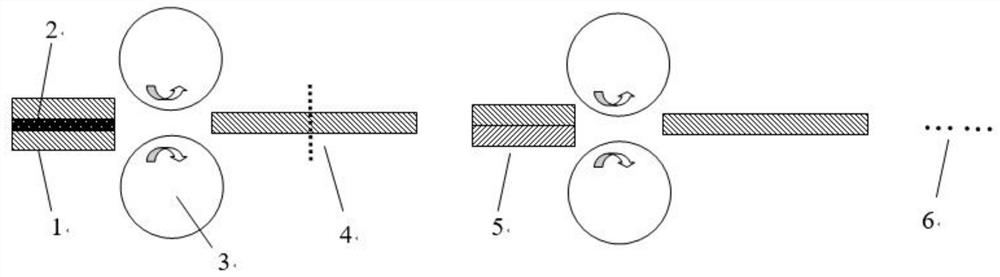

[0025] A preparation method of a lead-carbon composite material, comprising the steps of:

[0026] 1) Preparation of carbon solution: Add 2 grams of graphite into absolute ethanol, then place it in an ultrasonic cleaner at 50°C with an ultrasonic frequency of 80 Hz, and process it for 50 minutes to obtain a uniformly dispersed carbon solution;

[0027] 2) Pretreatment of the surface of the lead plate: the surface of the lead plate is pretreated by degreasing treatment, grinding treatment and acid solution cleaning in sequence; the specific steps of the degreasing treatment are: put the lead plate in a degreasing agent, and heat Soak for 20 minutes, then wash away the residual solution on the surface with deionized water; wherein, the degreasing agent is a tetrasodium solution, and its composition is: 20g / L NaOH, 20g / L NaOH 3 PO 4 , 10g / L Na 2 CO 3 , 4g / L Na 4 SiO 4 . The concrete steps of acid solution cleaning are: acidic solution impregnates the lead plate with smooth ...

Embodiment 2

[0033] A preparation method of a lead-carbon composite material, comprising the steps of:

[0034] 1) Preparation of carbon solution: 0.5 g of graphene was added to acetone, and then placed in an ultrasonic cleaner at 50° C., with an ultrasonic frequency of 80 Hz, and ultrasonically treated for 50 minutes to obtain a uniformly dispersed carbon solution;

[0035] 2) Pretreatment of the surface of the lead plate: the surface of the lead plate is pretreated by degreasing treatment, grinding treatment and acid solution cleaning in sequence; Soak for 10 minutes, then wash away the residual solution on the surface with deionized water; wherein, the degreasing agent is a tetrasodium solution, and its composition is: 20g / L NaOH, 20g / L NaOH 3 PO 4 , 10g / L Na 2 CO 3 , 4g / L Na 4 SiO 4 . The concrete steps of acid solution cleaning are: acidic solution impregnates the lead plate with smooth surface for 5-10 seconds and rinses lead plate with deionized water; acidic solution is made ...

Embodiment 3

[0041] A preparation method of a lead-carbon composite material, comprising the steps of:

[0042] 1) Preparation of carbon solution: Add 33 mg of carbon black to DMF, then place it in an ultrasonic cleaner at 50°C with an ultrasonic frequency of 80 Hz, and process it for 50 minutes to obtain a uniformly dispersed carbon solution;

[0043] 2) Pretreatment of the surface of the lead plate: the surface of the lead plate is pretreated by degreasing treatment, grinding treatment and acid solution cleaning in sequence; the specific steps of the degreasing treatment are: put the lead plate in a degreasing agent, and heat Soak for 20 minutes, then wash away the residual solution on the surface with deionized water; wherein, the degreasing agent is a tetrasodium solution, and its composition is: 20g / L NaOH, 20g / L NaOH 3 PO 4 , 10g / L Na 2 CO 3 , 4g / L Na 4 SiO 4 . The concrete steps of acid solution cleaning are: acidic solution impregnates the lead plate with smooth surface for 5-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com