A dual-phase in-situ nano-reinforced titanium-based composite material and its preparation method

A titanium-based composite material and nano-enhanced technology, which is applied in the direction of additive processing, additive manufacturing, and process efficiency improvement, can solve problems such as easy contamination, reduced wettability, and difficult-to-form geometric structures, and achieve enhanced dislocations Strengthening effect, enhanced fine grain strengthening effect, effect of refining material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

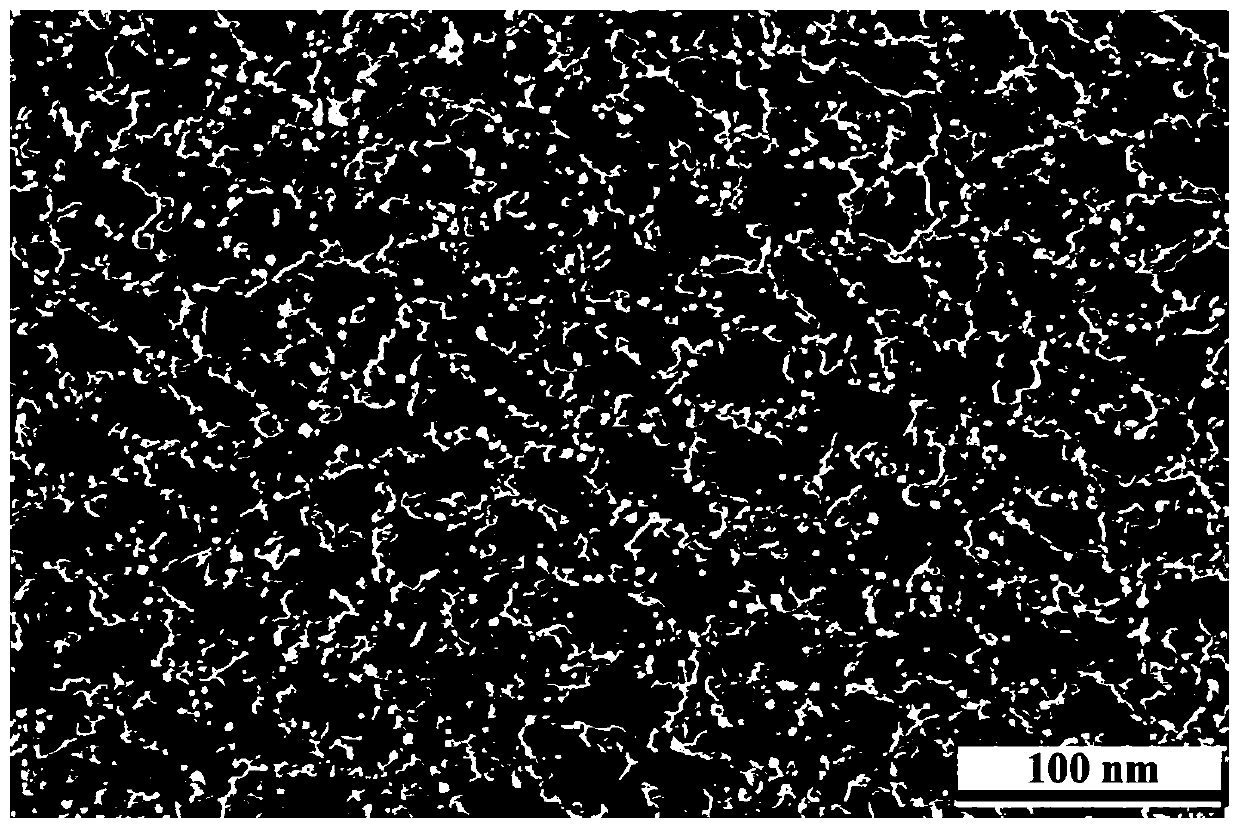

Image

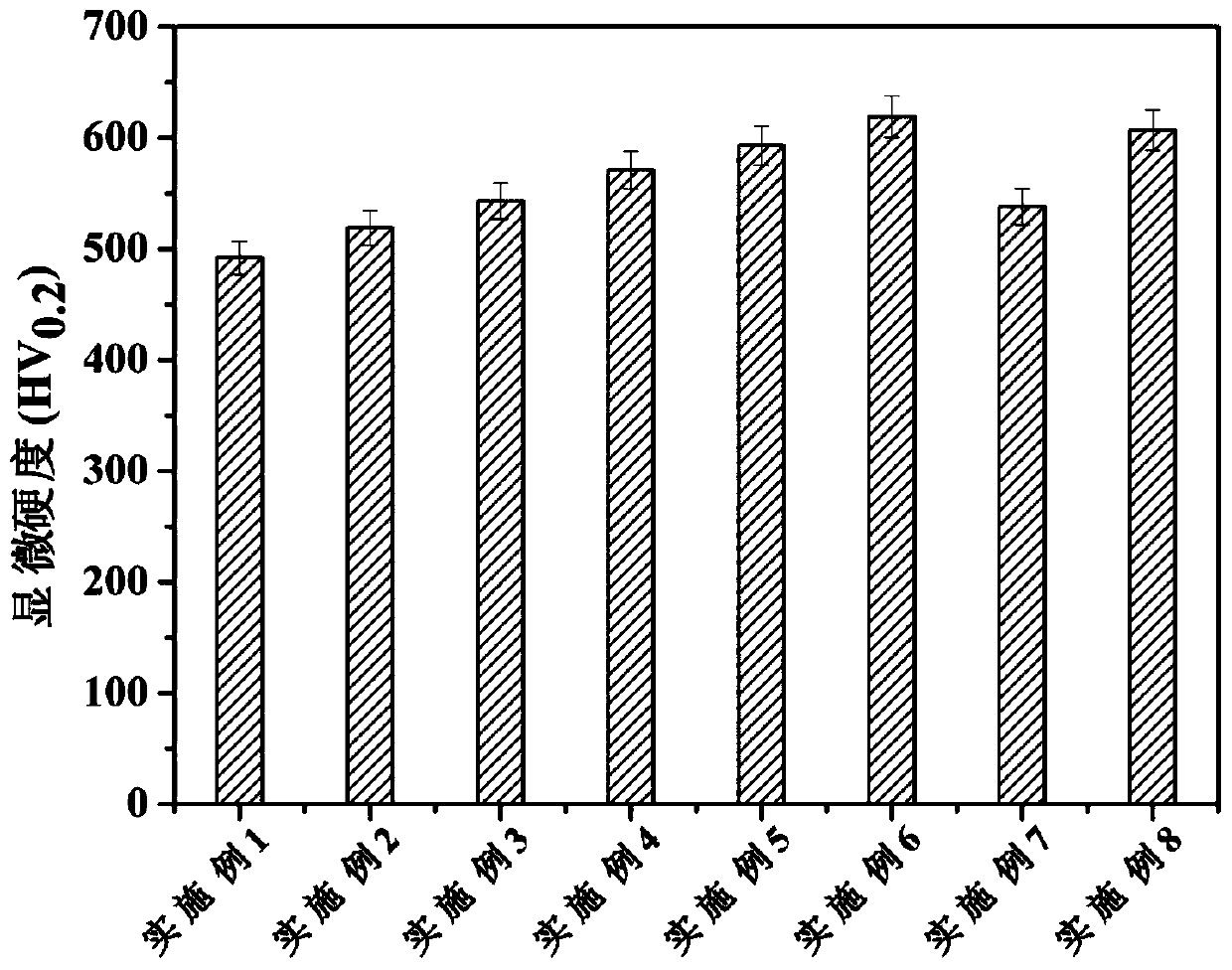

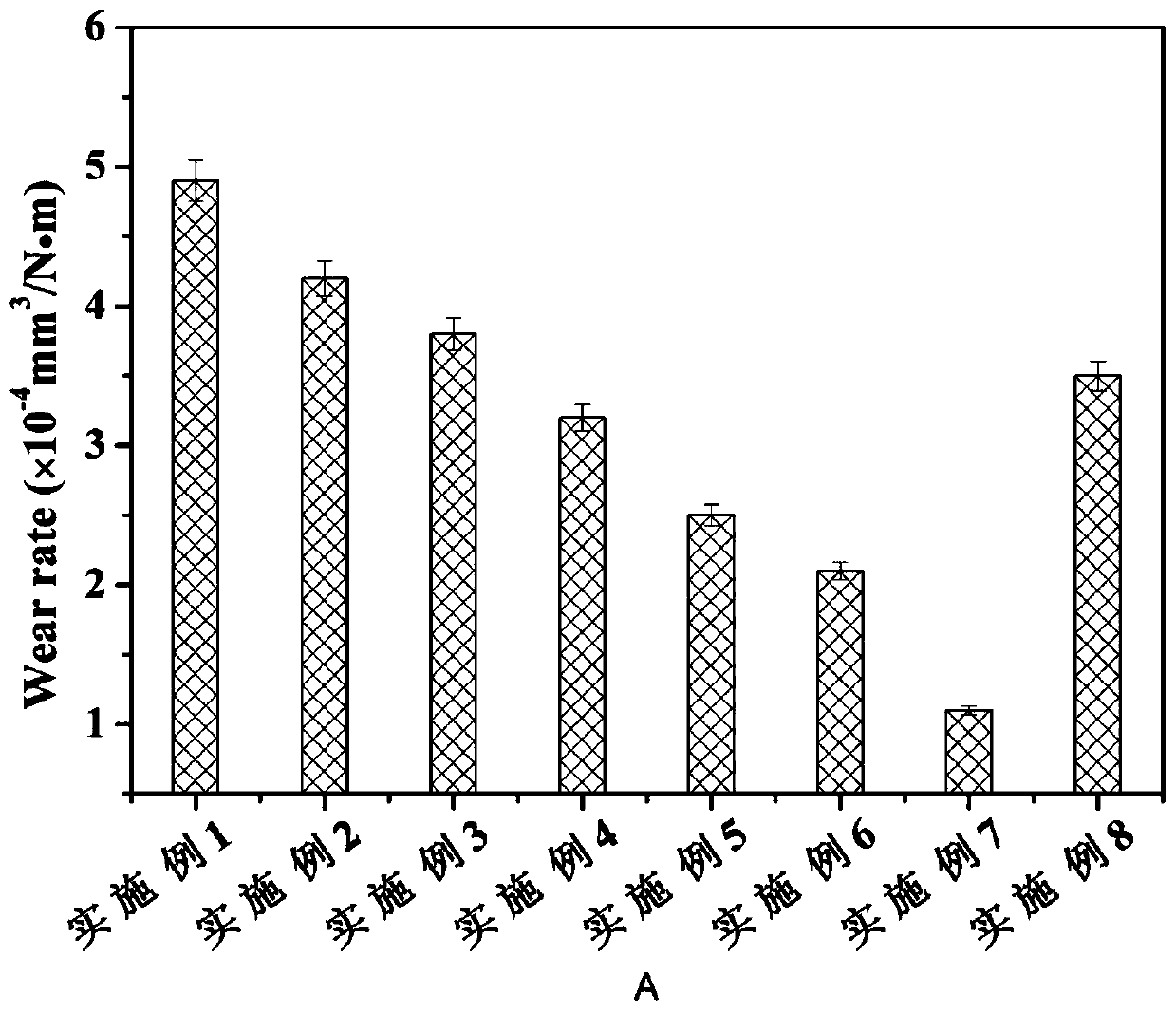

Examples

Embodiment 1

[0027] Step (1): According to the mass ratio of spherical AlSi12 alloy powder and pure titanium powder dedicated to laser 3D printing to 1:99, weigh them respectively, wherein the particle size of the spherical pure titanium powder is 15-53 μm, the purity is 99.7%, and the particle size of the spherical AlSi12 alloy powder is The diameter is 10-30 μm, and the purity is 99.7%. Under the protection environment of high-purity argon gas with a purity of 99.99%, the high-energy ball milling process is used at a speed of 200rpm. Forward rotation ball milling for 10 minutes, intermittent air cooling for 5 minutes, followed by reverse ball milling for 10 minutes, Alternating 5 cycles, ball milling and mixing the spherical powder and then drying to obtain a uniformly mixed composite material forming powder;

[0028]Step (2): Place the uniformly mixed dry pure titanium-AlSi12 alloy composite material forming powder in the step (1) in the powder cylinder of the laser selective melting equ...

Embodiment 2

[0030] Different from Example 1, in this example, the titanium alloy is set as Ti in step (1) 6 Al 4 V, the mass ratio of spherical AlSi12 alloy powder to pure titanium powder is set to 1:54, the ball mill speed is set to 300rpm, and the energy density in step (2) is set to 200J / m 3 , other parameters are the same as in Example 1.

Embodiment 3

[0032] Different from embodiment 2, in this embodiment, the titanium alloy is set as Ti in step (1) 2 Al 1.5 Mn alloy, ball mill speed is set to 200rpm, the laser body energy density is set to 120J / m in step (2) 3 . Other parameters are identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com