A kind of equipment and process for continuous production of rubber vulcanization accelerator tetramethylthiuram disulfide

A technology of tetramethylthiuram disulfide and rubber vulcanization, which is applied in organic chemistry and other fields, and can solve problems such as large investment, hidden dangers, safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

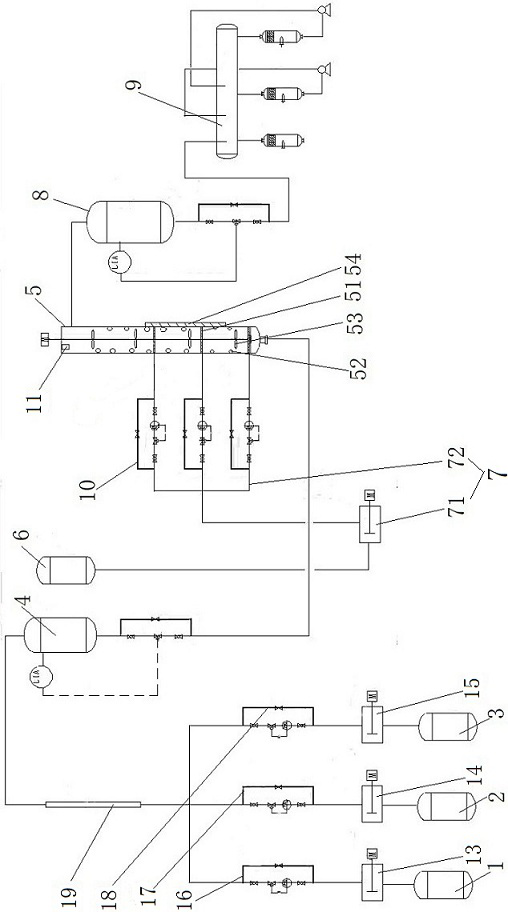

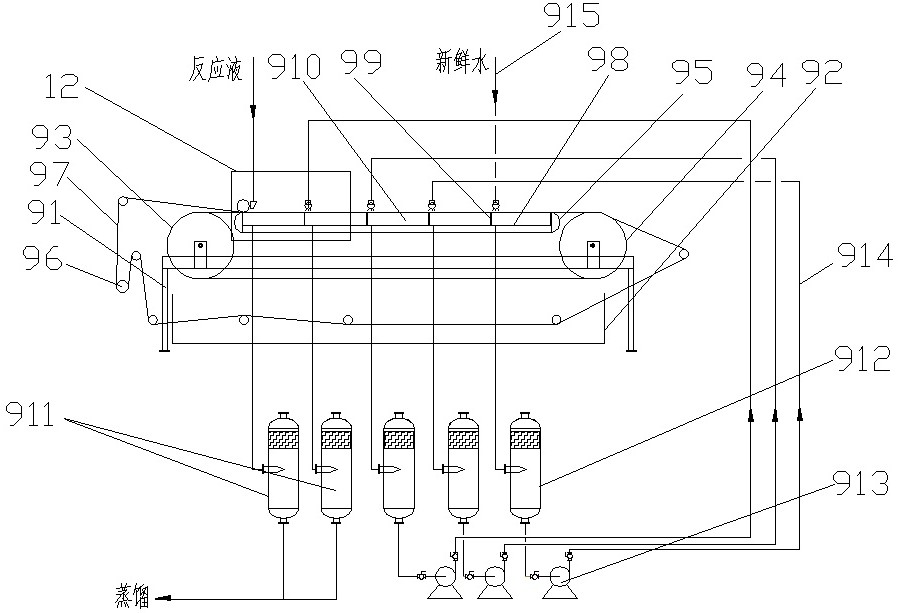

Method used

Image

Examples

specific Embodiment approach 2

[0044] Specific embodiment two: according to the steps adopted in the technique of the above-mentioned continuous production of rubber vulcanization accelerator tetramethylthiuram disulfide, the solvent is used at 2000L / h, dimethylamine is at 280L / h, and carbon disulfide is at a flow rate of 140L / h Pump into the mixing tank 4 through the static mixer 19, and pump into the tower reactor 5 with a metering pump while maintaining a certain liquid level, and the hydrogen peroxide in the hydrogen peroxide tank 6 enters the tower reactor in three stages at a flow rate of 140 L / h , keep the reaction temperature at 45°C, after the reaction, the solid separated by the reverse elution device 9 is dried by drying equipment, and the material is quantified for 8 hours, and the finished product of rubber vulcanization accelerator tetramethylthiuram disulfide is produced in total The amount is 2.04 tons, and the recovery rate is 96% based on dimethylamine, and the initial melting point of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com