A composite flexible negative electrode material for lithium battery and a preparation method thereof

A negative electrode material, lithium battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as consumption of active materials, thermal runaway of battery system, battery short circuit, etc., to achieve excellent rate performance, high cycle efficiency, and good cycle life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

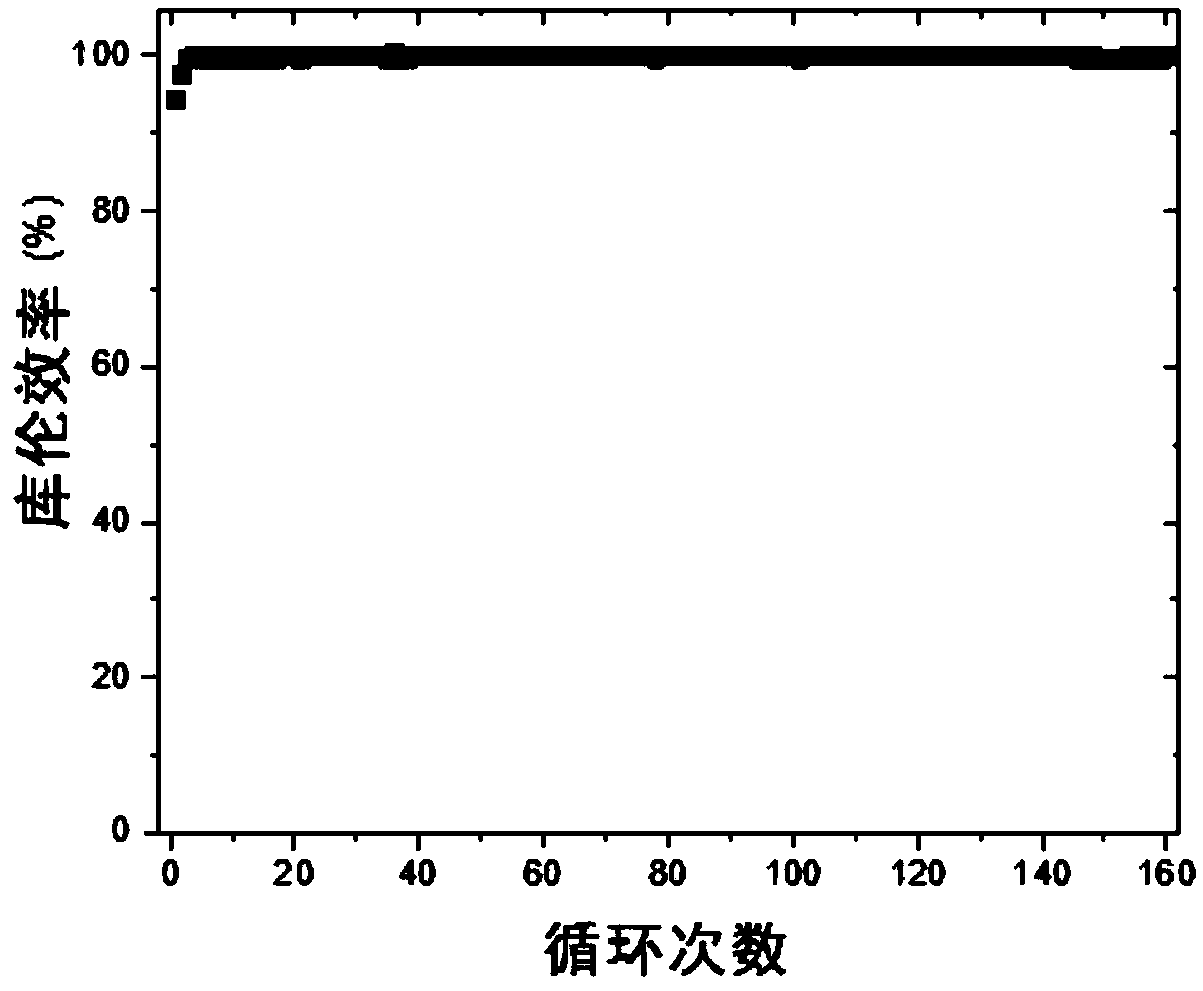

[0030] The thickness is 330μm, the area weight density is 12mg cm -2 , the surface resistivity is less than 3mΩcm 2 The carbon cloth is cut into electrode sheets, and then the two poles of the battery are formed with metal lithium, and the battery is assembled in a glove box. The electrolyte is a DOL / DME (v / v=1:1) solution of 1M LiTFSI, and 1w% of LiNO 3 . At 35% overintercalation, at 1mA cm -2 99.9% Coulombic efficiency can still be maintained when cycling 160 cycles at the highest current density, the results are as follows figure 1 shown.

Embodiment 2

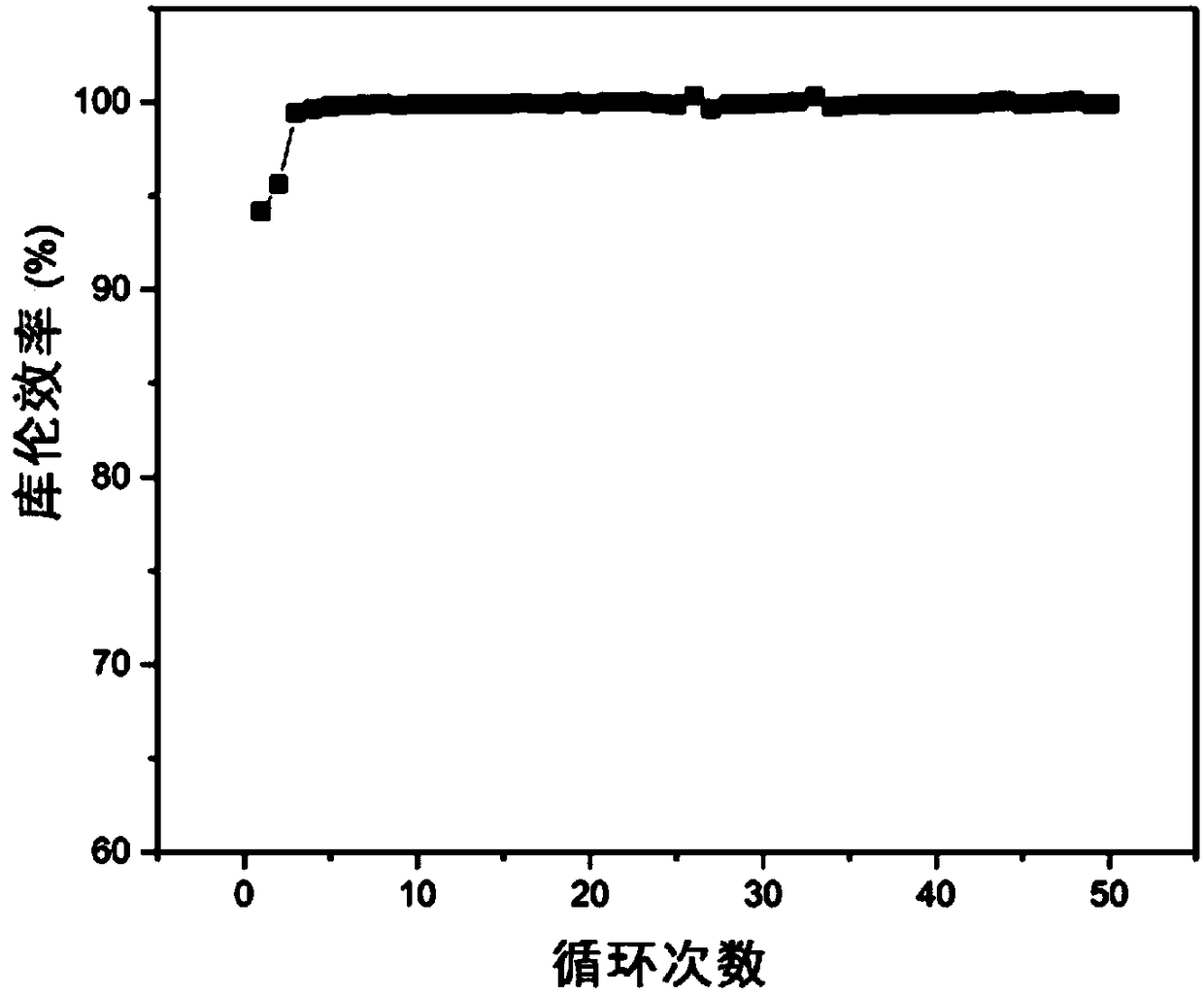

[0032] The thickness is 330μm, the area weight density is 12mg cm -2 , the surface resistivity is less than 3mΩcm 2 The carbon cloth is cut into electrode sheets, and then the two poles of the battery are formed with metal lithium, and the battery is assembled in a glove box. The electrolyte is a DOL / DME (v / v=1:1) solution of 1M LiTFSI, and 1w% of LiNO 3 . At 35% overintercalation, at 3mA cm -2 99.7% Coulombic efficiency can still be maintained when cycling 50 cycles at the same current density, the results are as follows figure 2 shown.

Embodiment 3

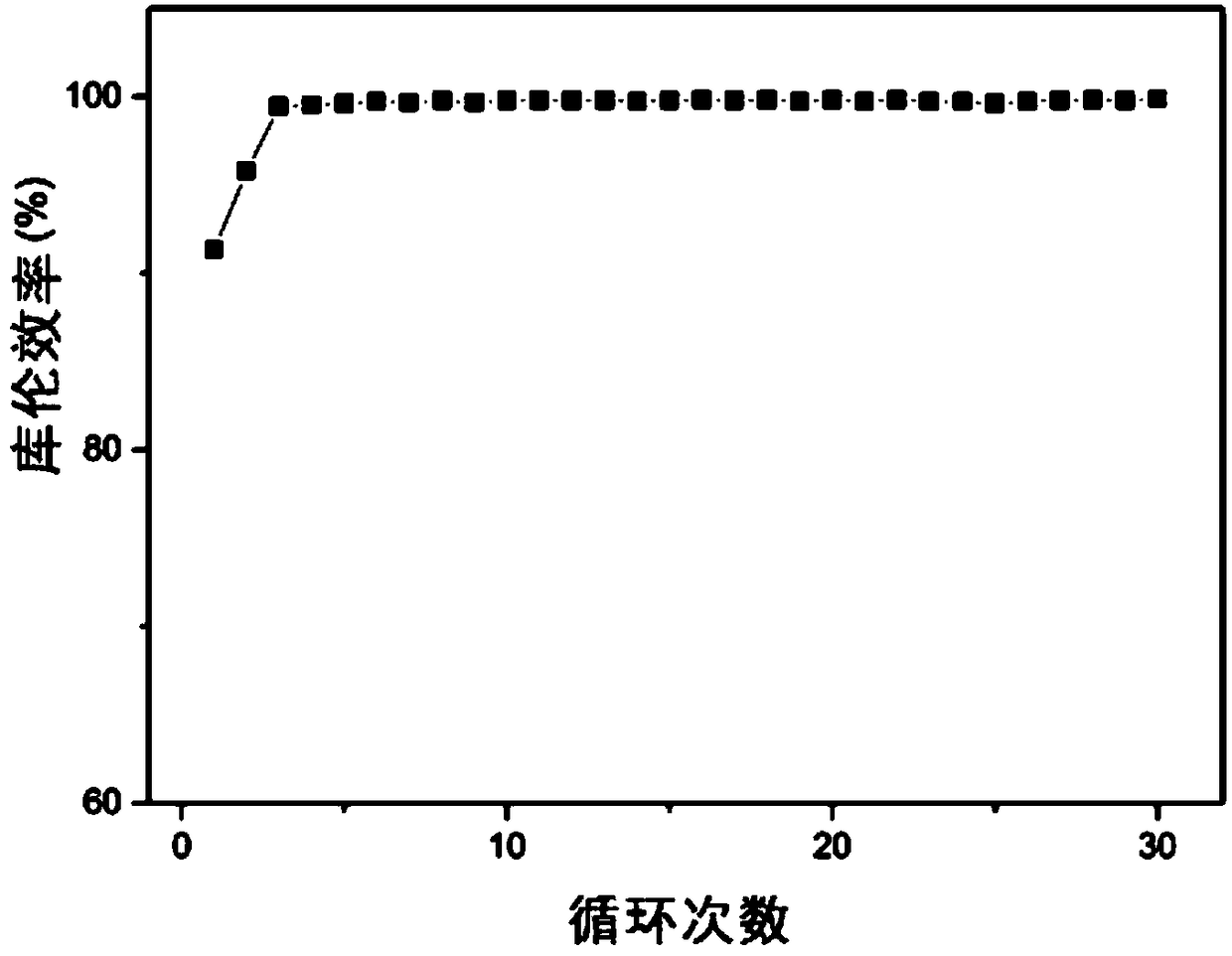

[0034] The thickness is 330μm, the area weight density is 12mg cm -2 , the surface resistivity is less than 3mΩcm 2 The carbon cloth is cut into electrode sheets, and then the two poles of the battery are formed with metal lithium, and the battery is assembled in a glove box. The electrolyte is a DOL / DME (v / v=1:1) solution of 1M LiTFSI, and 1w% of LiNO 3 . At 35% overintercalation, at 5mA cm -2 99.6% Coulombic efficiency can still be maintained when cycling for 30 cycles at the highest current density. The results are as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com