Anode sulfur poisoning regeneration device and regeneration method for solid oxide fuel cell

A solid oxide, fuel cell technology, used in the disposal/recycling of fuel cells, fuel cells, battery recycling, etc., can solve problems such as insecurity and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

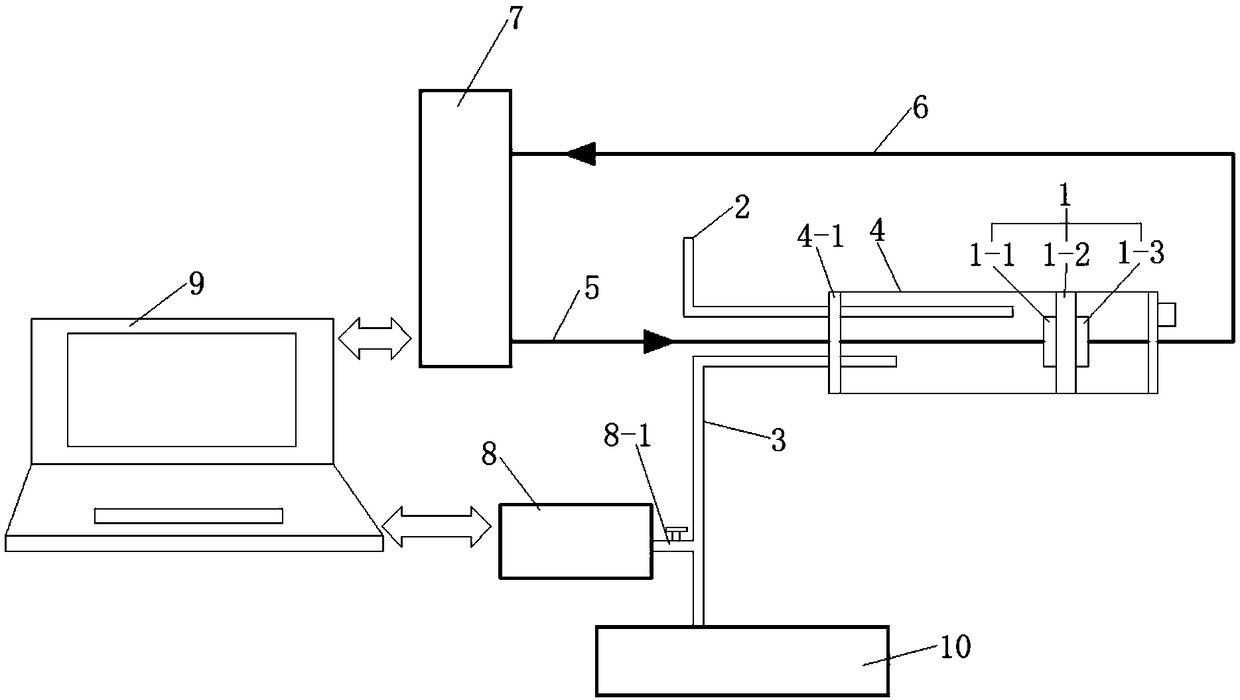

[0015] Specific Embodiment 1: The solid oxide fuel cell anode sulfur poisoning regeneration device in this embodiment includes a solid oxide fuel cell 1, an air inlet pipe 2, an air outlet pipe 3, a battery fixing pipe 4, an anode current lead 5, a cathode current lead 6, an electric ChemStation 7, Mass Spectrometer 8 and H 2 S absorption pool 10, solid oxide fuel cell 1 is fixed in one end of battery fixing tube 4, electrolyte 1-2 is sandwiched between battery anode 1-1 and battery cathode 1-3, the other end of battery fixing tube 4 Sealed by the sealing cover 4-1, the battery anode 1-1 is in the anode gas chamber formed by the sealing of the battery fixing tube 4 and the sealing cover 4-1, the battery cathode 1-3 is in the cathode gas chamber, and the cathode gas chamber is opened with air intake The inlet pipe 2 communicates with the anode gas chamber and extends into the battery fixing pipe 4, one end of the gas outlet pipe 3 communicates with the anode gas chamber, and th...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solid oxide fuel cell 1 is an anode-supported type, an electrolyte-supported type or a cathode-supported type.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the cross-sectional shape of the solid oxide fuel cell 1 is circular or square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com