Telescoping extraction device for efficiently recovering valuable components of manganese slag

An extraction device and technology of manganese slag, applied in the field of retractable extraction device, can solve the problems of high cost, restricting the development of electrolytic manganese slag, low efficiency, etc., and achieve the effect of efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

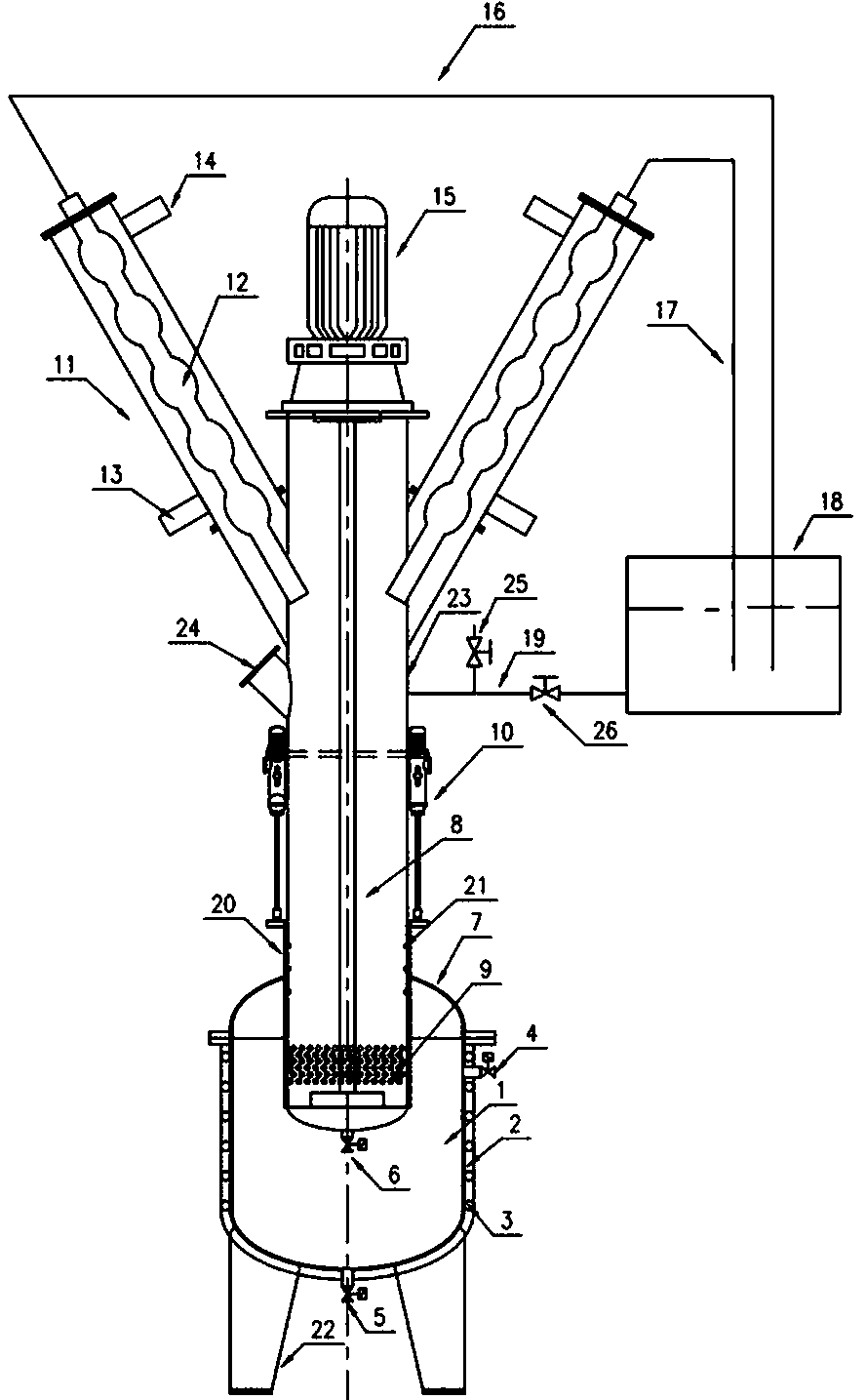

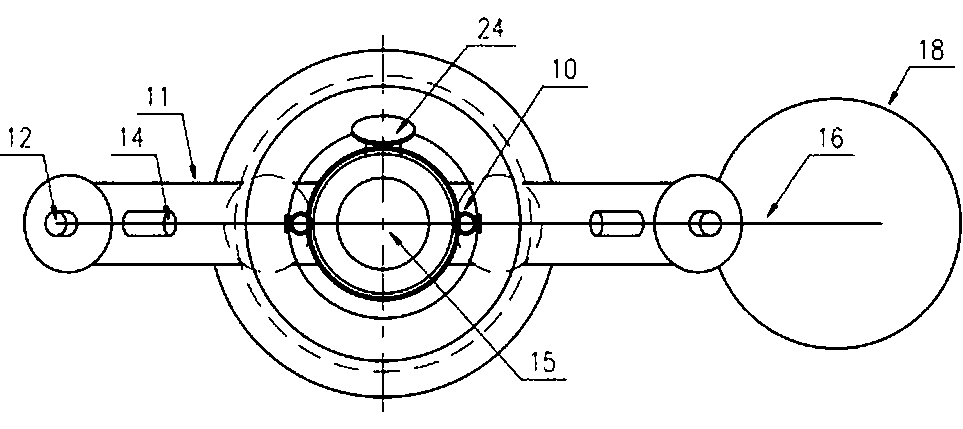

[0022] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0023] Such as figure 1 and figure 2 The telescopic extraction device for efficiently recovering valuable components of manganese slag as shown includes a heating tank body 1, a heating tank cover 7, an agitator 8, a hydraulic telescopic rod 10, a condensation pipe 11, a recovery tank 18 and a sliding pipe 23, and the heating tank body The bottom is provided with a liquid outlet valve 5, the upper part is provided with a liquid inlet valve 4, the outer wall is provided with a jacket 2, and the jacket is provided with a heating coil 3, and the upper end of the heating tank 1 is connected with the heating tank cover 7 through a flange. There is a sleeve 20 in the center of the heating tank cover, and the sliding tube 23 is inserted into the sleeve 20, which can slide up and down flexibly in the sleeve 20. The bottom of the sliding tube 23 is provided with a drain valve,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com