Thiobacillus ferrooxidans with high production of magnetosome and application thereof

A technology of Thiobacillus ferrooxidans and ferrous oxide, applied in the biological field, can solve problems such as scarcity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] The technical solution of the present invention is not limited to the specific implementations listed below, but also includes any combination of the specific implementations.

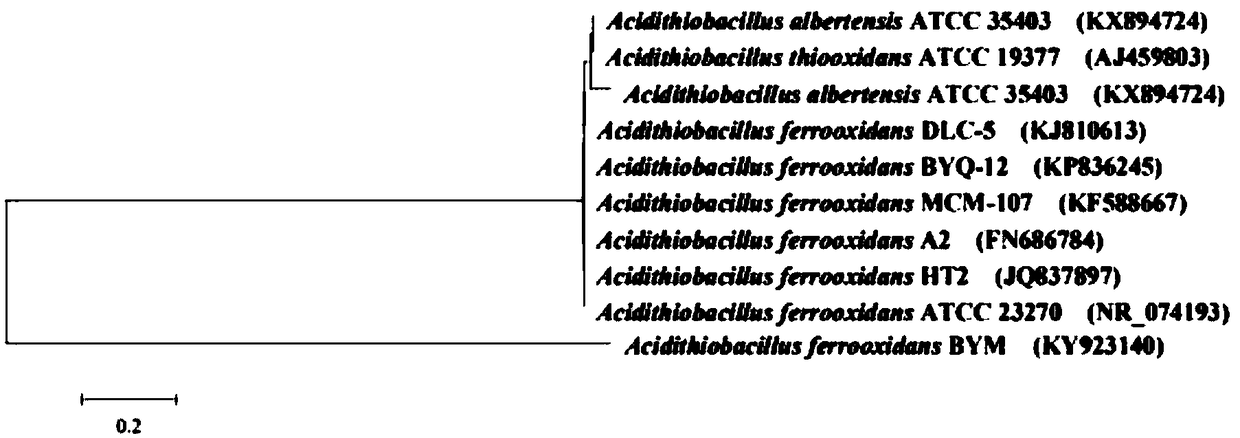

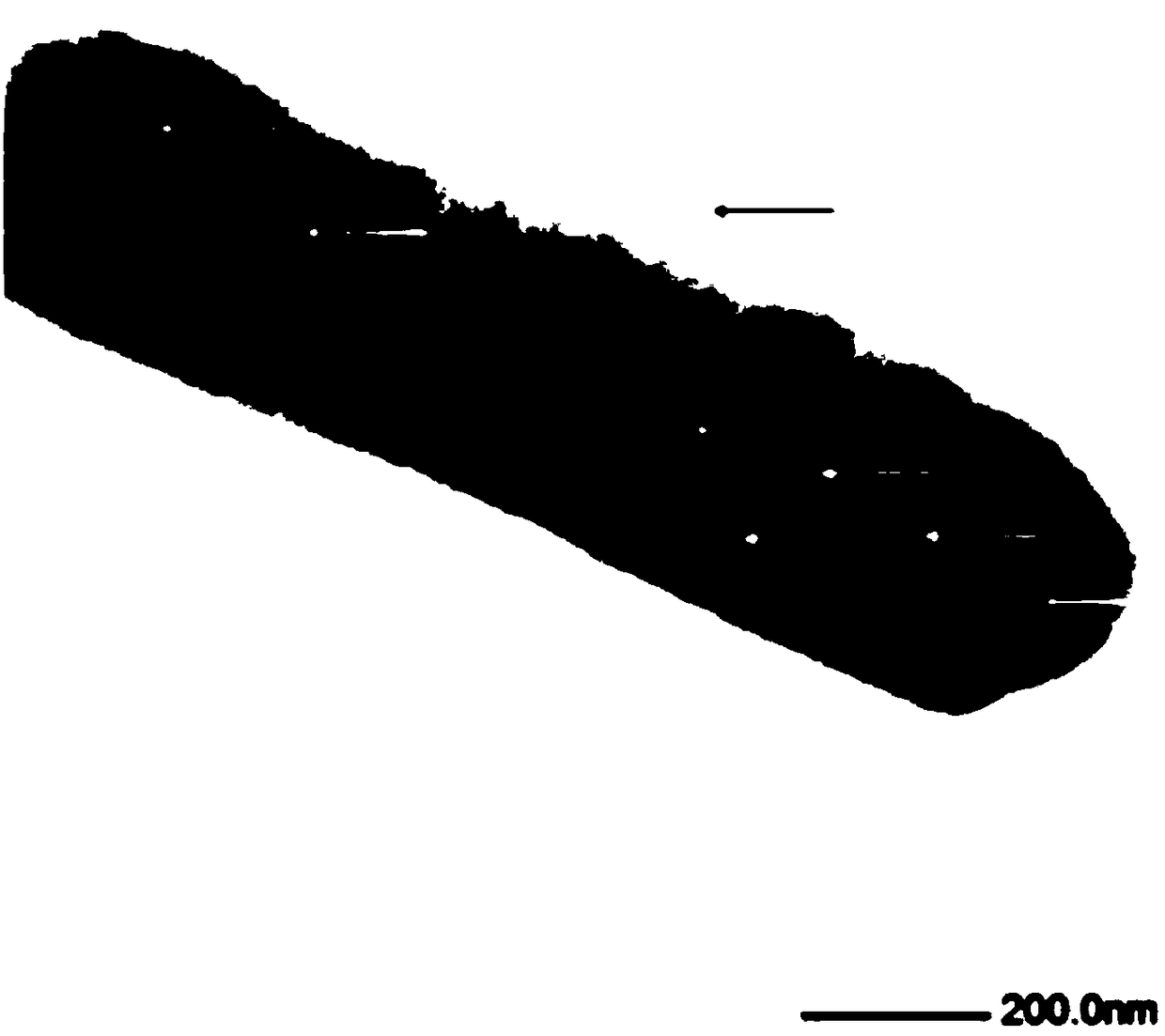

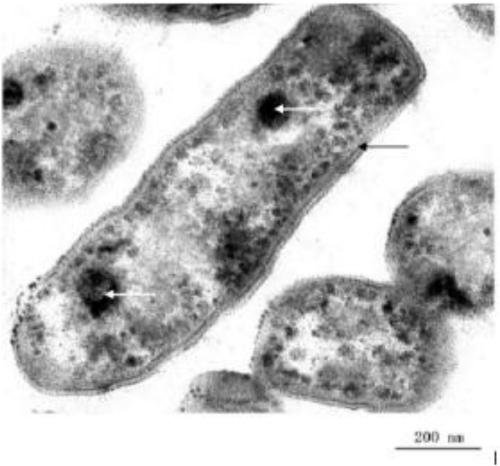

[0028] The invention provides a high-yield magnetosome-producing Thiobacillus ferrooxidans BYM (Acidithiobacillus ferrooxidans BYM, A. ferrooxidans BYM) and its application. A strain of A.ferrooxidansBYM with high magnetosome production was bred by the combination of Race-track liquid magnetophoresis separation and semi-solid plate magnetophoresis separation. The strain has the advantage of being easy to cultivate, the growth period is 24-36 hours, and 6.28 mg of magnetosomes are produced per 1 g of bacteria. The laboratory can use the high-yield magnetosome strain A.ferrooxidans BYM as a biological factory to produce magnetosomes, and the produced magnetosomes can be used for drug carriers and other purposes.

[0029] The following is an introduction through a specific implementation manner. ...

specific Embodiment approach 1

[0032] Acidithiobacillus ferrooxidans (A. ferrooxidans) was isolated from a water sample of a copper mine in Baiyin City, Gansu Province.

[0033] Acidophilus ferrooxidans (A.ferrooxidans) was inoculated in the liquid culture medium, and the liquid culture medium was prepared according to the following ratio: in every 1000ml liquid culture medium, by 2.4g (NH 4 ) 2 SO 4 , 0.1g of KCl, 0.5g of K 2 HPO 4 , 0.5g of MgSO 4 ·7H 2 O, 0.01g of Ca(NO 3 ) 2 , 40g of FeSO 4 and the remainder of distilled water, and adjust the pH to 2.0.

[0034] According to the inoculum amount of 8-12% (v / v), in this embodiment, the acidophilic Thiobacillus ferrooxidans (A. ferrooxidans) is inoculated in the liquid medium. Cultivate on a shaker at 120 rpm at a temperature of 30° C., and cultivate for 24 to 48 hours until the logarithmic phase is ready for use.

specific Embodiment approach 2

[0035] Separation of Thiobacillus ferrooxidans Race-track liquid magnetophoresis:

[0036] ① Take the bacterium liquid cultured to the logarithmic phase in Embodiment 1, and filter it with a microporous membrane (the pore size is 0.22 μm) to obtain acidophilic Thiobacillus ferrooxidans (A.ferrooxidans) thallus;

[0037] ② Use 1mL of H at pH 2 2 SO 4 Rinse the solution and centrifuge at 2000rmp for 5min;

[0038] ③Take the supernatant, centrifuge at 10000rmp for 5min, and take the precipitate;

[0039] ④ Repeat steps ② and ③ 3 times to obtain precipitation;

[0040] ⑤ Suspend with 500 μL of 0K solution, and collect in Pasteur tube for 30 minutes;

[0041] ⑥Take 3 Pasteur tubes, and add the bacterial solution to the end of the Pasteur tubes. After 30 minutes of magnetic collection, take the tip 2cm, suck out the liquid with a 1ml syringe, inject it into the liquid medium, and cultivate it on a shaker at 120rpm at a temperature of 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com