Steel plate having thickness of 150 mm, low compression ratio and low Z-direction performance, and production method thereof

A production method and compression ratio technology, applied in the field of metallurgy, can solve problems such as long waiting time and reduce production rhythm, and achieve the effects of increasing production rhythm, increasing production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

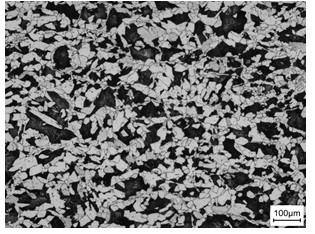

Image

Examples

Embodiment 1

[0026] Table 1 shows the chemical composition and mass percentage of the 150 mm thick low compression ratio Z-direction performance steel plate Q420C-Z35 in this example.

[0027] The production method of the 150mm thick low compression ratio Z-direction performance steel plate Q420C-Z35 in this embodiment includes smelting, continuous casting, heating, controlled rolling and controlled cooling processes, and the specific process steps are as follows:

[0028] (1) Smelting process: After RH vacuum degassing treatment, [H] in molten steel is 0.0001%;

[0029] (2) Continuous casting process: the casting speed of the continuous casting machine is 0.85m / min, the superheat of molten steel in the tundish is 23°C, and the technology of continuous casting dynamic light reduction and casting slab solidification end heavy reduction technology is adopted, and the solid phase ratio is distributed according to the solid phase ratio. Segment reduction, the total reduction of the slab is 21m...

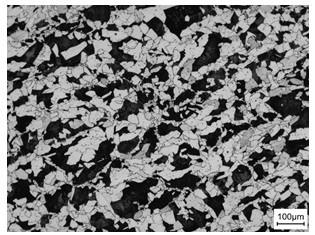

Embodiment 2

[0036] Table 1 shows the chemical composition and mass percentage of the 150 mm thick low compression ratio Z-direction performance steel plate in this example.

[0037] The production method of the 150mm thick low compression ratio Z-direction performance steel plate Q420C-Z35 in this embodiment includes smelting, continuous casting, heating, controlled rolling and controlled cooling processes, and the specific process steps are as follows:

[0038] (1) Smelting process: After RH vacuum degassing treatment, [H] in molten steel is 0.0001%;

[0039] (2) Continuous casting process: The casting speed of the continuous casting machine is 0.89m / min, the superheat of molten steel in the tundish is 17°C, and the technology of continuous casting dynamic light reduction and casting slab solidification end heavy reduction technology is adopted, and the solid phase ratio is distributed according to the solid phase ratio. Segment reduction, the total reduction of the slab is 19mm, the red...

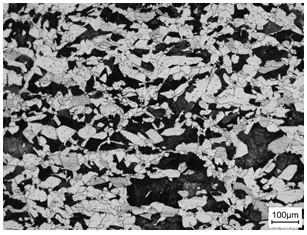

Embodiment 3

[0046] Table 1 shows the chemical composition and mass percentage of the 150 mm thick low compression ratio Z-direction performance steel plate Q345B-Z15 in this example.

[0047] The production method of the 150mm thick low compression ratio Z-direction performance steel plate Q345B-Z15 in this embodiment includes smelting, continuous casting, heating, controlled rolling and controlled cooling processes, and the specific process steps are as follows:

[0048] (1) Smelting process: After RH vacuum degassing treatment, [H] in molten steel is 0.0002%;

[0049] (2) Continuous casting process: the casting speed of the continuous casting machine is 0.85m / min, the superheat of molten steel in the tundish is 15°C, the technology of continuous casting dynamic light reduction and casting slab solidification end heavy reduction technology is adopted, and the solid phase ratio is distributed according to the solid phase ratio. Segment reduction, the total reduction of the slab is 19mm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com