Processing method for vacuum low-temperature preconditioned sturgeon flesh products

A technology of vacuum low temperature and processing method, which is applied to the preservation of meat/fish, the function of food ingredients, and the preservation of food ingredients as antimicrobial, etc. Long time and other problems, to achieve the effect of good quality maintenance, improve sensory quality, and less weight loss after pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

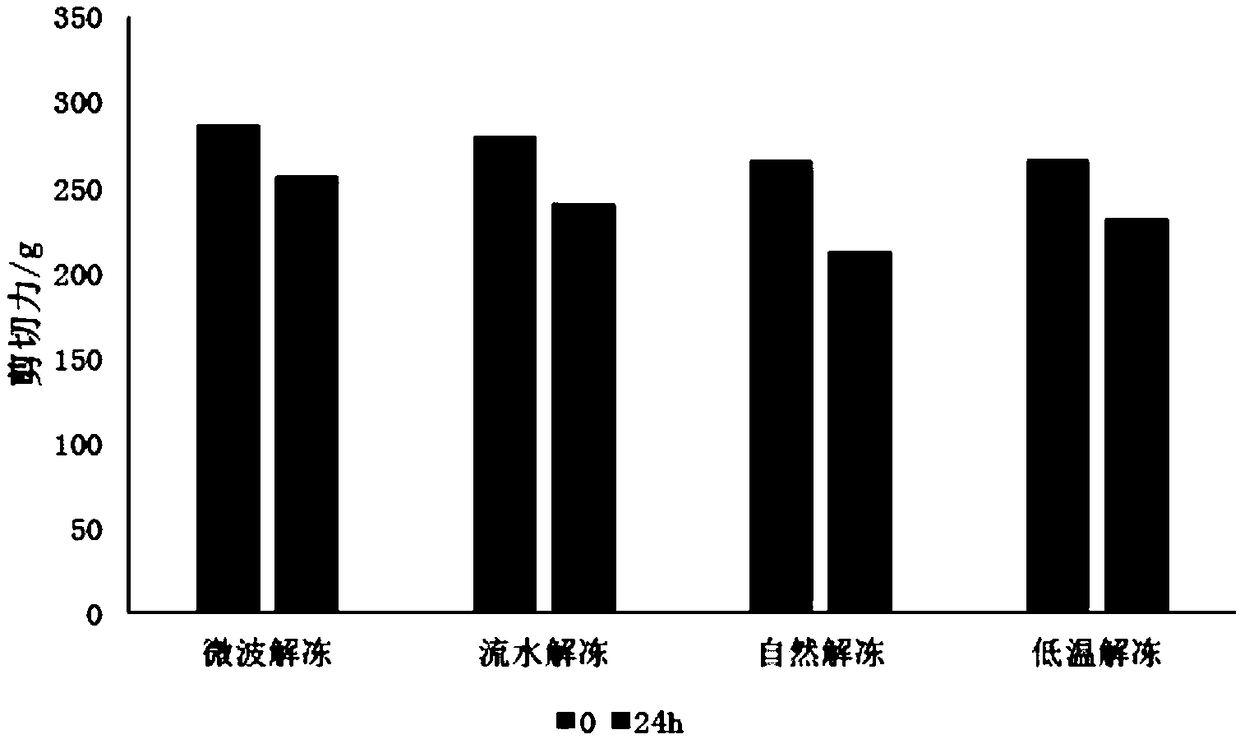

[0028] 1) Thaw raw meat

[0029] Put the frozen sturgeon meat in a thawing solution containing 2% sodium citrate and 0.01% kojic acid, and thaw it with a microwave with a frequency of 910MHz. The method of using the thawing liquid is to place the frozen sturgeon meat in three thawing pools filled with thawing liquid 2 to 2.5 times the weight of the sturgeon meat in turn for thawing. The processing time in the three thawing pools is 2h, 1h, and 0.5h respectively. .

[0030] 2) Plastic surgery

[0031] Slice the thawed sturgeon meat, specifically, cut the fish skin along the back spine of the sturgeon, and cut the back white meat into fillets along the texture, each fillet is 3cm in length, 3cm in width and 2cm in thickness .

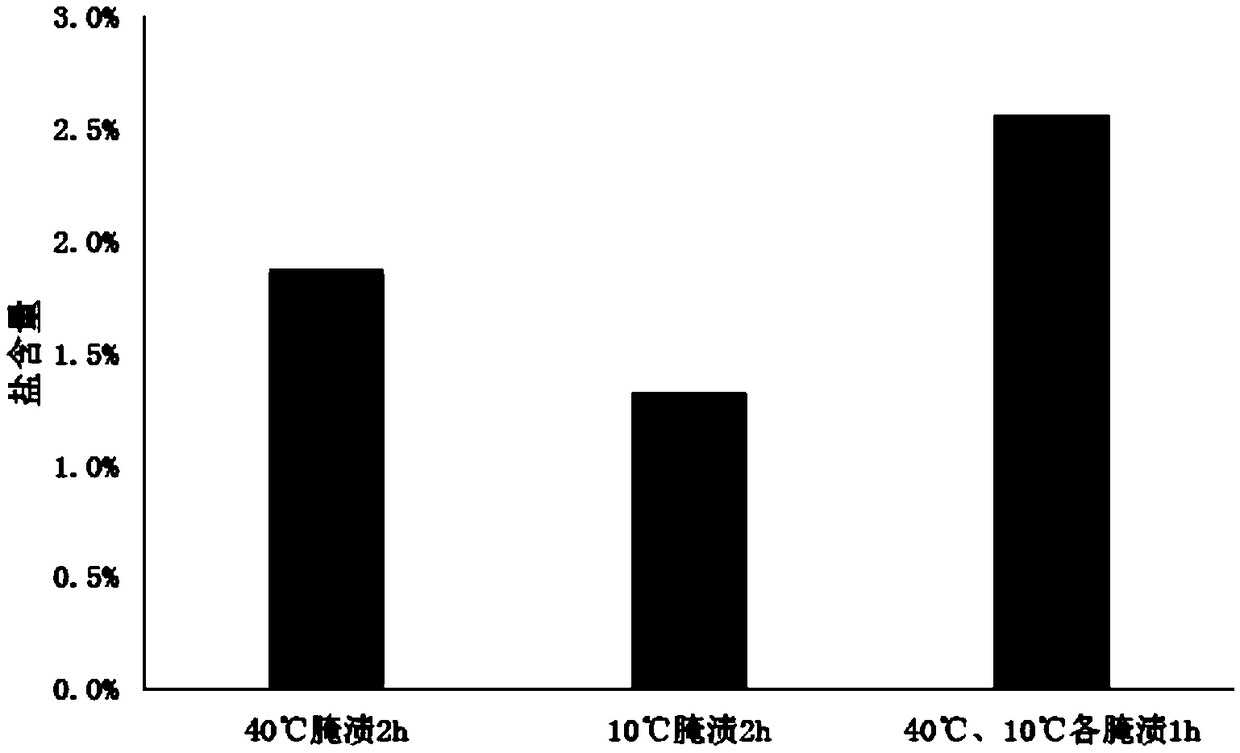

[0032] 3) Vacuum secondary pickling

[0033] Soak the shaped fish fillets in the pickling solution, the formula of the pickling solution is 0.015% of gallic acid, 2% of salt and 1% of xylitol. Under the condition of vacuum degree of 45kPa.

[0034] ...

Embodiment 2

[0046] 1) Thaw raw meat

[0047] Put the frozen sturgeon meat in a thawing solution containing 3% sodium citrate and 0.015% kojic acid, and thaw it with a microwave with a frequency of 920MHz. The method of using the thawing liquid is to place the frozen sturgeon meat in three thawing pools filled with thawing liquid 2 to 2.5 times the weight of the sturgeon meat in turn for thawing. The processing time in the three thawing pools is 2h, 1h, and 0.5h respectively. .

[0048] 2) Plastic surgery

[0049] Slice the thawed sturgeon meat, specifically, cut the skin along the back spine of the sturgeon, and cut the back white meat into fillets along the texture, each fillet is 5cm in length, 5cm in width and 3cm in thickness .

[0050] 3) Vacuum secondary pickling

[0051] Soak the shaped fish fillets in a pickling solution, the formula of which is 0.01% gallic acid, 3% salt and 1.5% xylitol. Under the condition of 55kPa.

[0052] 4) Low temperature pre-curing

[0053]The pick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com