A method for preparing ceramic composite armor

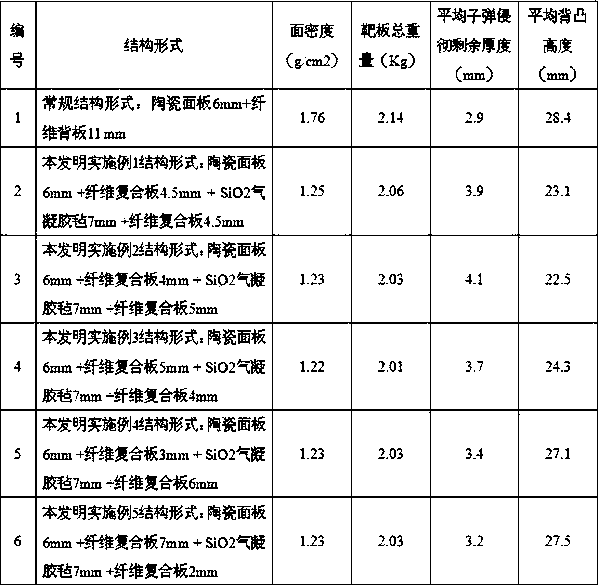

A ceramic composite and armor technology, which is applied to the structure of armor plates, armor, ceramic layered products, etc., can solve the problems of large back convex deformation, insufficient ability to transmit and absorb impact, and bulky weapons and equipment, etc. The effect of convex deformation, improved ballistic performance, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

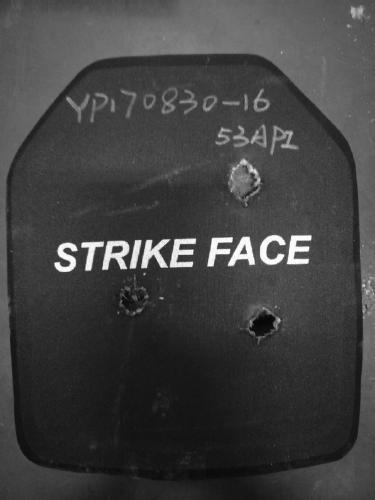

Image

Examples

Embodiment 1

[0029] A method for preparing ceramic composite armor, is characterized in that, comprises the following steps:

[0030] Step 1. Prepare a SiC ceramic board, two UHMWPE fiber composite boards, and a SiO 2 Airgel felt and a mold for preparing the ceramic composite armor, the mold is placed horizontally and the cover plate of the mold is opened, and a release agent is evenly applied on the inner cavity surface of the mold;

[0031] Among them, the thickness of the SiC ceramic plate is 6mm, the thickness of the two UHMWPE fiber composite plates is 4.5mm, and the SiO 2 The thickness of the airgel felt is 7mm, both when the thickness of the SiC ceramic plate provided by the invention is d, the thickness of the two UHMWPE fiber composite plates is 0.6-0.9d, and the SiO 2 The thickness of the airgel blanket is within the preferred thickness range of 1-1.4d;

[0032] Among them, the tensile strength of UHMWPE fiber composite board at room temperature is greater than 3500MPa, and the e...

Embodiment 2

[0044] A method for preparing ceramic composite armor, is characterized in that, comprises the following steps:

[0045] Step 1. Prepare a SiC ceramic board, two UHMWPE fiber composite boards, and a SiO 2 Airgel felt and a mold for preparing the ceramic composite armor, the mold is placed horizontally and the cover plate of the mold is opened, and a release agent is evenly applied on the inner cavity surface of the mold;

[0046] Among them, the thickness of the SiC ceramic plate is 6mm, the thickness of one UHMWPE fiber composite plate is 4mm, the thickness of the other UHMWPE fiber composite plate is 5mm, and the SiO 2 The thickness of the airgel felt is 7mm, both when the thickness of the SiC ceramic plate provided by the invention is d, the thickness of the two UHMWPE fiber composite plates is 0.6-0.9d, and the SiO 2 The thickness of the airgel blanket is within the preferred thickness range of 1-1.4d;

[0047] Among them, the tensile strength of UHMWPE fiber composite b...

Embodiment 3

[0059] A method for preparing ceramic composite armor, is characterized in that, comprises the following steps:

[0060] Step 1. Prepare a SiC ceramic board, two UHMWPE fiber composite boards, and a SiO 2 Airgel felt and a mold for preparing the ceramic composite armor, the mold is placed horizontally and the cover plate of the mold is opened, and a release agent is evenly applied on the inner cavity surface of the mold;

[0061] Among them, the thickness of the SiC ceramic plate is 6mm, the thickness of one UHMWPE fiber composite plate is 4mm, the thickness of the other UHMWPE fiber composite plate is 5mm, and the SiO 2 The thickness of the airgel felt is 7mm, both when the thickness of the SiC ceramic plate provided by the invention is d, the thickness of the two UHMWPE fiber composite plates is 0.6-0.9d, and the SiO 2 The thickness of the airgel blanket is within the preferred thickness range of 1-1.4d;

[0062] Among them, the tensile strength of UHMWPE fiber composite b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com