High-barrier composite packaging film

A technology of composite packaging film and packaging film, which is applied in the field of packaging materials, can solve the problems of internal substance pollution, invisible packaging film, poor thermal stability, etc., to improve acceptability, improve identification and operability, and improve shelf life. The effect of life and shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

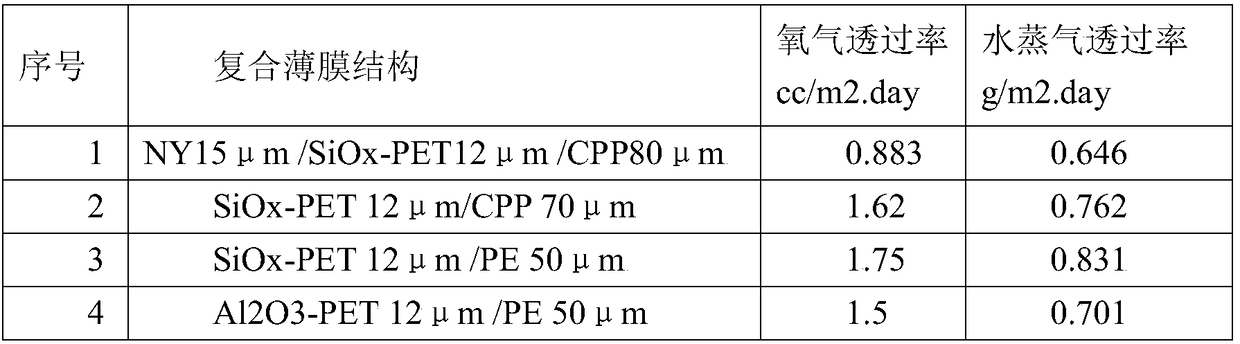

[0025] A polyester film (SiOx-PET 12 μm) coated with a silicon oxide nano-film with a thickness of 0.02 μm was used as a barrier layer, a 80 μm thick cast polypropylene (CPP 80 μm) was used as a composite film heat seal layer, and a 15 μm thick nylon film ( PA15μm) as a composite film mechanical reinforcement layer. The three layers were laminated together by a dry composite process, and placed in a constant temperature oven at 50°C for curing. After curing for 48 hours, a three-layer silicon oxide high barrier composite film of PA15μm / SiOx-PET12μm / CPP80μm was obtained. The weight ratio of glue for dry compounding is: (main agent: curing agent: ethyl acetate) ratio is 5:1:5.8. The amount of gluing is 3.5g / m2. Dry composite line speed is 100m / min.

Embodiment 2

[0027] The polyester film (SiOx-PET12μm) coated with silicon oxide nano-film with a thickness of 0.02μm is used as the barrier layer, and the cast polypropylene (CPP70μm) with a thickness of 70μm is used as the heat-sealing layer of the composite film. The two layers were laminated together by a dry composite process, and placed in a constant temperature oven at 50°C for curing. After curing for 48 hours, a SiOx-PET12μm / CPP70μm double-layer silicon oxide high barrier composite film was obtained. The weight ratio of glue for dry compounding is: (main agent: curing agent: ethyl acetate) ratio is 5:1:5.8. The amount of gluing is 3.5g / m2. Dry composite line speed is 100m / min.

Embodiment 3

[0029] The polyester film (SiOx-PET12 μm) coated with silicon oxide nano-film with a thickness of 0.02 μm is used as the barrier layer, and the heat-sealable polyethylene film (PE50 μm) with a thickness of 50 μm is used as the heat-seal layer of the composite film. The two layers were laminated together by a dry composite process, and placed in a constant temperature oven at 50°C for curing. After curing for 48 hours, a SiOx-PET12μm / PE50μm double-layer silicon oxide high-barrier composite film was obtained. The weight ratio of glue for dry compounding is: (main agent: curing agent: ethyl acetate) ratio is 5:1:5.8. The amount of gluing is 3.5g / m2. Dry composite line speed is 100m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com