Styrenic thermoplastic elastomer/polystyrene composite membrane and preparation method thereof

A thermoplastic elastomer and styrene-based technology, which is applied in the field of quaternary ammonium salt type anion exchange membrane alkaline fuel cells, can solve the problem that polystyrene lacks toughness, swelling and damage, mechanical stability and ion transport properties are difficult to give full play to benzene. The performance of ethylene-based thermoplastic elastomers, etc., to achieve good mechanical properties and dimensional stability, and improve the effect of ion transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

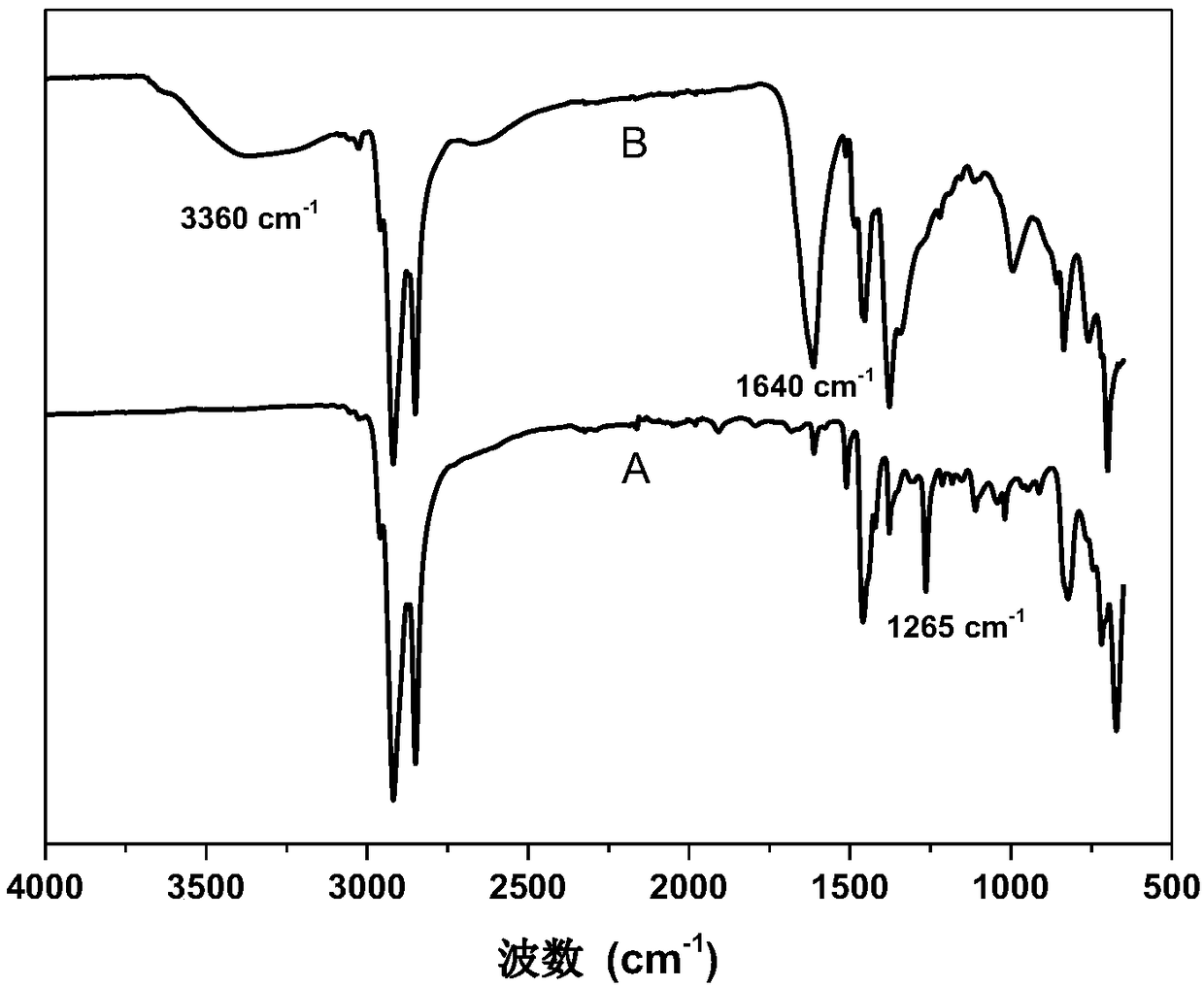

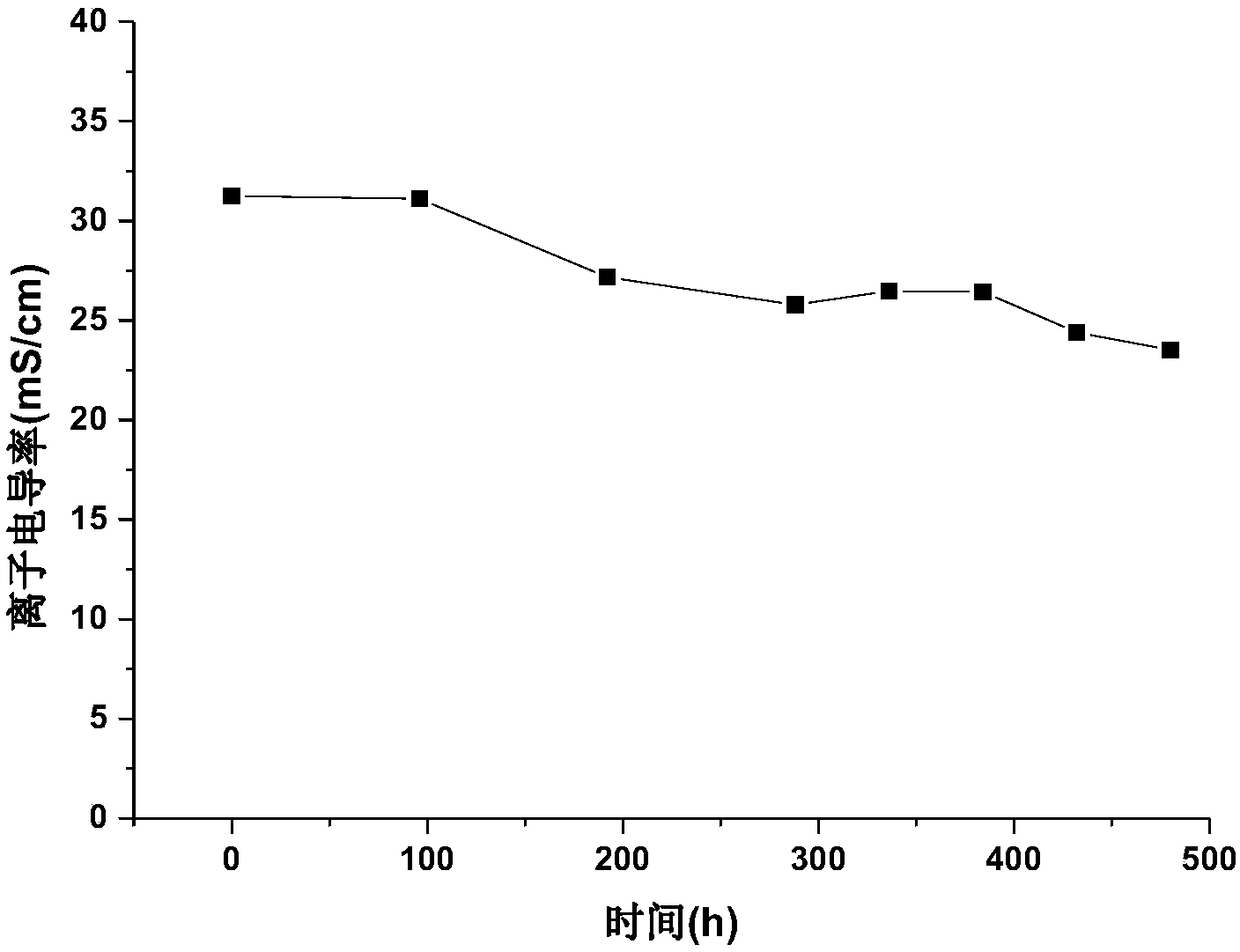

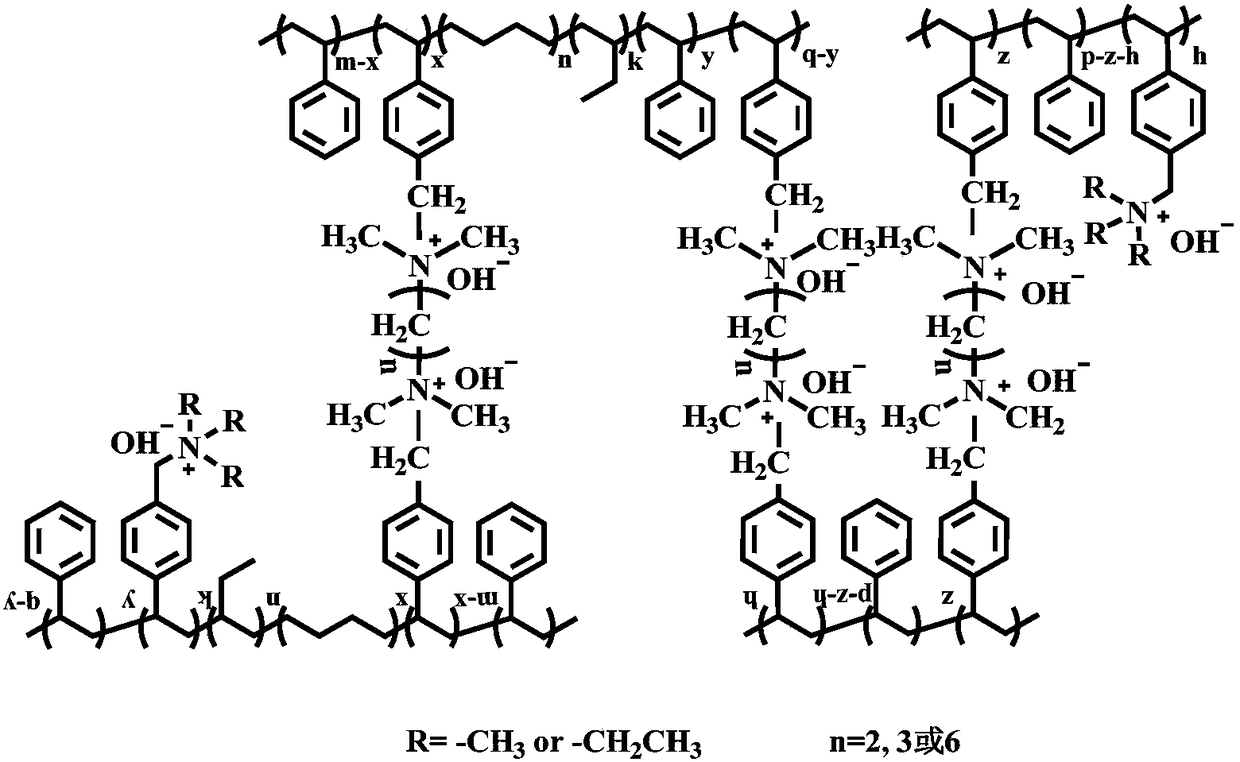

[0021] 2g of SEBS (6mmol styrene unit) was added into a three-necked flask equipped with a magnetic stirring bar, and 30mL of carbon tetrachloride was added thereto. After it was dissolved at 35°C, 0.56 mL (4.8 mmol) of anhydrous tin tetrachloride was added to the above solution under an ice-water bath and stirred for 30 minutes. Then 1.8 g (9.6 mmol) BCMB was added dropwise to the solution, and reacted at 18° C. for 24 hours. After the reaction is over, pour the reaction solution into dilute hydrochloric acid solution to remove the catalyst, then pour it into ethanol to obtain the crude product, dissolve it in tetrahydrofuran and precipitate it with ethanol again, and wash it with ethanol and water until there is no chloride ion in the solution Then vacuum dry at 35°C for 12 hours.

[0022] Weigh 0.5g chloromethylated SEBS, dissolve it with 10ml chloroform at room temperature, add 0.079mL TMHDA under ice-water bath after the dissolution is complete, stir vigorously for 5 min...

Embodiment 2

[0025] 2g of SEBS (6mmol styrene unit) was added into a three-necked flask equipped with a magnetic stirring bar, and 30mL of carbon tetrachloride was added thereto. After it was dissolved at 35°C, 0.70 mL (6 mmol) of anhydrous tin tetrachloride was added to the above solution under an ice-water bath and stirred for 30 minutes. Then, 3.4 g (18 mmol) of BCMB was added dropwise to the solution, and reacted at 18° C. for 24 hours. After the reaction is over, pour the reaction solution into dilute hydrochloric acid solution to remove the catalyst, then pour it into ethanol to obtain the crude product, dissolve it in toluene and precipitate it with ethanol again, and wash it with ethanol and water until there is no chloride ion in the solution Then vacuum dry at 35°C for 12 hours.

[0026] 2gPS(M n =11000) (20 mmol styrene unit) was added to a three-necked flask equipped with a magnetic stirrer, and 60 mL of carbon tetrachloride was added thereto. After it was dissolved at 35° C...

Embodiment 3

[0031]2g of SEBS (6mmol styrene unit) was added into a three-necked flask equipped with a magnetic stirring bar, and 30mL of carbon tetrachloride was added thereto. After it was dissolved at 35°C, 0.84 mL (7.2 mmol) of anhydrous tin tetrachloride was added to the above solution under an ice-water bath and stirred for 30 minutes. Then 5.4 g (28.8 mmol) of BCMB was added dropwise to the solution, and reacted at 18° C. for 24 hours. After the reaction is over, pour the reaction solution into dilute hydrochloric acid solution to remove the catalyst, then pour it into ethanol to obtain the crude product, dissolve it in xylene and precipitate it with ethanol again, and wash it with ethanol and water until there is no chlorine in the solution After ionization, dry in vacuum at 35°C for 12 hours.

[0032] 2gPS(M n =8000) (20 mmol styrene unit) was added to a three-necked flask equipped with a magnetic stirrer, and 60 mL of carbon tetrachloride was added thereto. After it was dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com