Preparation method of TPU for submachine gun transparent magazine

A submachine gun and transparent technology, which is applied in the field of preparation of TPU for submachine gun transparent magazines, can solve the problems of no transparent products and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

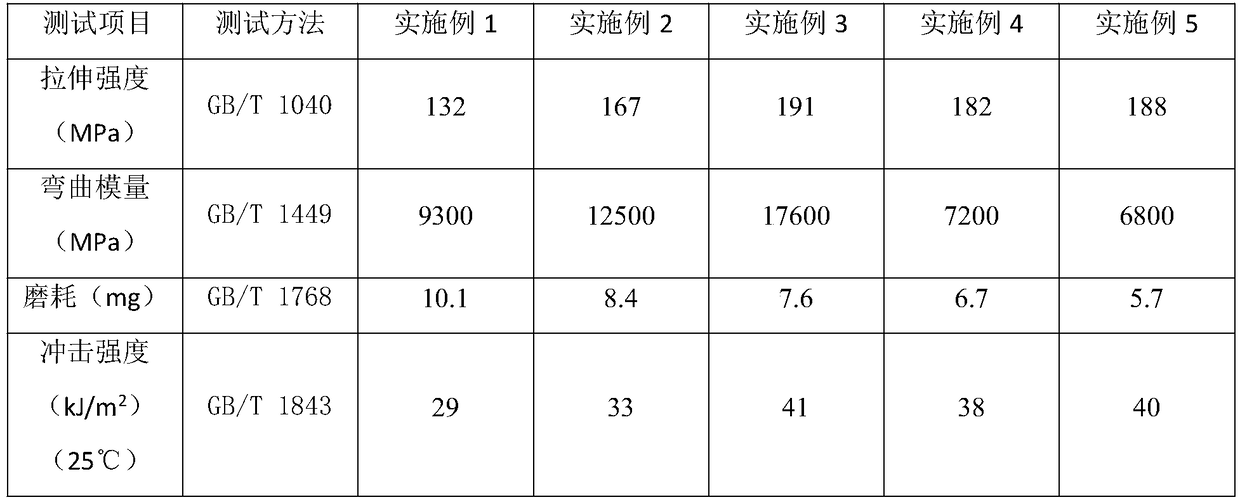

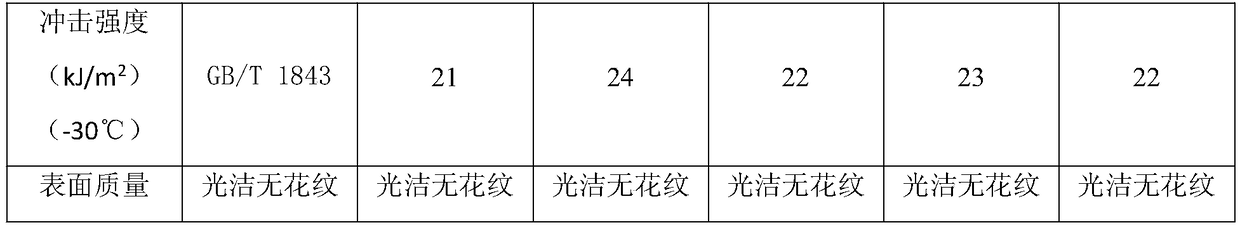

Examples

Embodiment 1

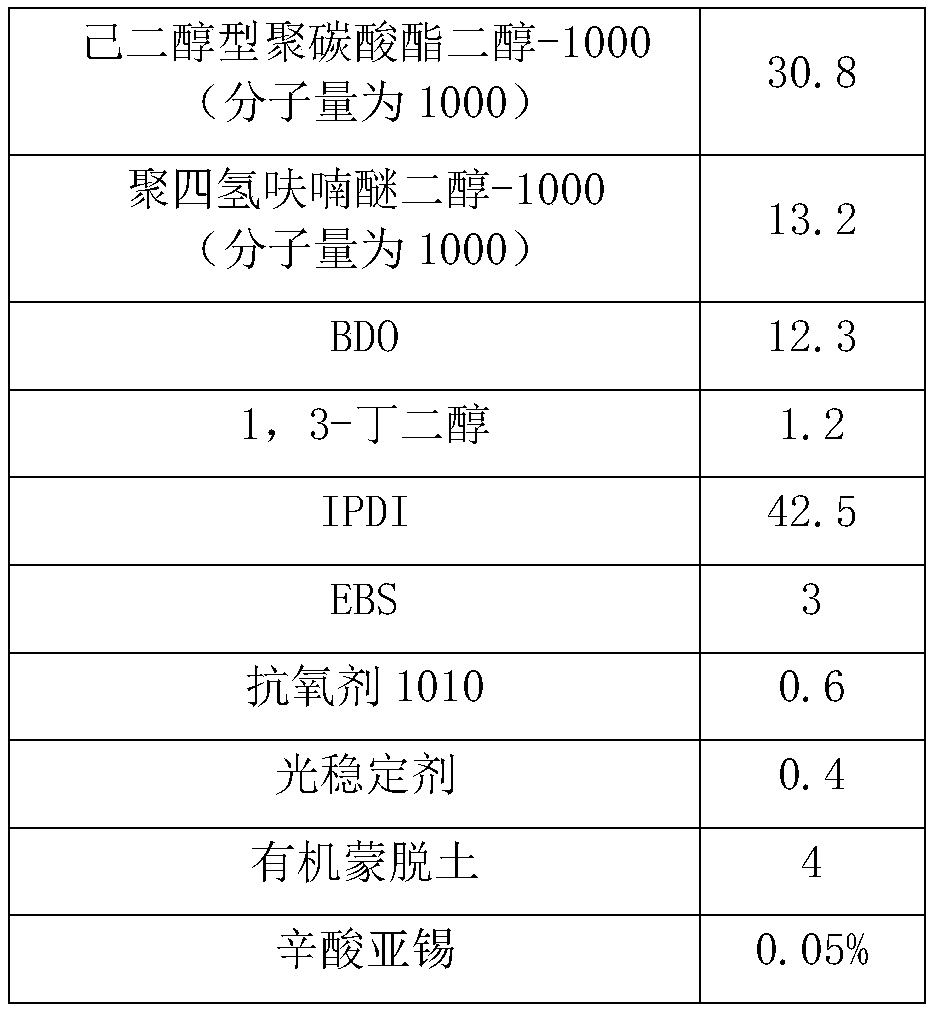

[0020] The formula of TPU particles is shown in Table 1:

[0021] Table 1

[0022]

[0023] (1) Fully mix the macromolecular glycol, antioxidant, lubricant, light stabilizer, and organotin catalyst according to the mass ratio, and heat to 120°C;

[0024] (2) Heating the diisocyanate to 60°C in another reaction kettle;

[0025] (3) Heat the chain extender to 60°C; inject the three components into the sprue of the twin-screw extruder according to the above-mentioned mass ratio setting flow rate, fully mix and completely react in the twin-screw extruder, and set the screw temperature to 130-240°C;

[0026] (4) Organic montmorillonite nanoparticles are added to the material at the twin-screw exhaust port through a side feeder, and are evenly mixed with the material in the screw;

[0027] (5) Cut the particles under water and dry at 80-110°C to obtain TPU particles with a Shore hardness of 75D;

[0028] (6) Take 60 parts of dried TPU particles and 10 parts of compatibilizer,...

Embodiment 2

[0033] Prepared according to the process of Example 1, the ratio of TPU particles to glass fibers is 50:50.

Embodiment 3

[0035] Prepared according to the process of Example 1, the ratio of TPU particles to glass fibers is 40:60.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com