Acrylate pressure sensitive adhesive and preparation method thereof, and electronic product

A pressure-sensitive adhesive and acrylate technology, applied in adhesives, ester copolymer adhesives, adhesive types, etc., can solve the problem of unsatisfactory high temperature resistance of double-sided adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] According to the second aspect of the present invention, the present invention provides the preparation method of described acrylate pressure-sensitive adhesive, comprising the following steps:

[0078] (a) Mix 30-35% of the mixed solution and 30-50% of the solvent, heat up to 85-90°C, add 15-25% of the initiator, and react for 25-35min; wherein, the mixed solution is soft Monomer, hard monomer, cross-linking monomer, heat-resistant monomer and tackifying resin are mixed;

[0079] (b) Add 65-75% of the mixed solution, 60-70% of the initiator and 50-70% of the solvent to the solution obtained in step (a) synchronously dropwise, after reacting for 80-100min, add the remaining initiator , After 25-35min, an acrylate pressure-sensitive adhesive was obtained.

[0080]It should be noted that the initiator in the above "adding the remaining initiator" exists in the form of an initiator solution, and the solvent of the initiator solution is the same as that used in the present...

Embodiment 1

[0094] 1. Acrylic pressure sensitive adhesive

[0095] An acrylate pressure-sensitive adhesive, mainly prepared from the following raw materials in parts by weight: the soft monomer is 50 parts of butyl acrylate and 25 parts of isooctyl acrylate; the hard monomer is 20 parts of vinyl acetate and 3 parts of acrylic acid Isobornyl ester; cross-linking monomers are 0.6 parts of acrylamide, 0.1 parts of 1,6-hexanediol diacrylate, 3.2 parts of glycidyl methacrylate, 1.5 parts of hydroxyethyl acrylate and 3 parts of acrylic acid; The body is 5 parts of bismaleimide; the initiator is 0.4 parts of benzoyl peroxide; the tackifying resin is 5 parts of hydrogenated rosin, the solvent is 160 parts of ethyl acetate and the curing agent is 0.6 parts of diisocyanate trimer N3390 .

[0096] 2. Preparation of acrylate pressure-sensitive adhesive

[0097] (1) Mix the soft monomer, hard monomer, cross-linking monomer, heat-resistant monomer and tackifying resin according to the ratio of step 1...

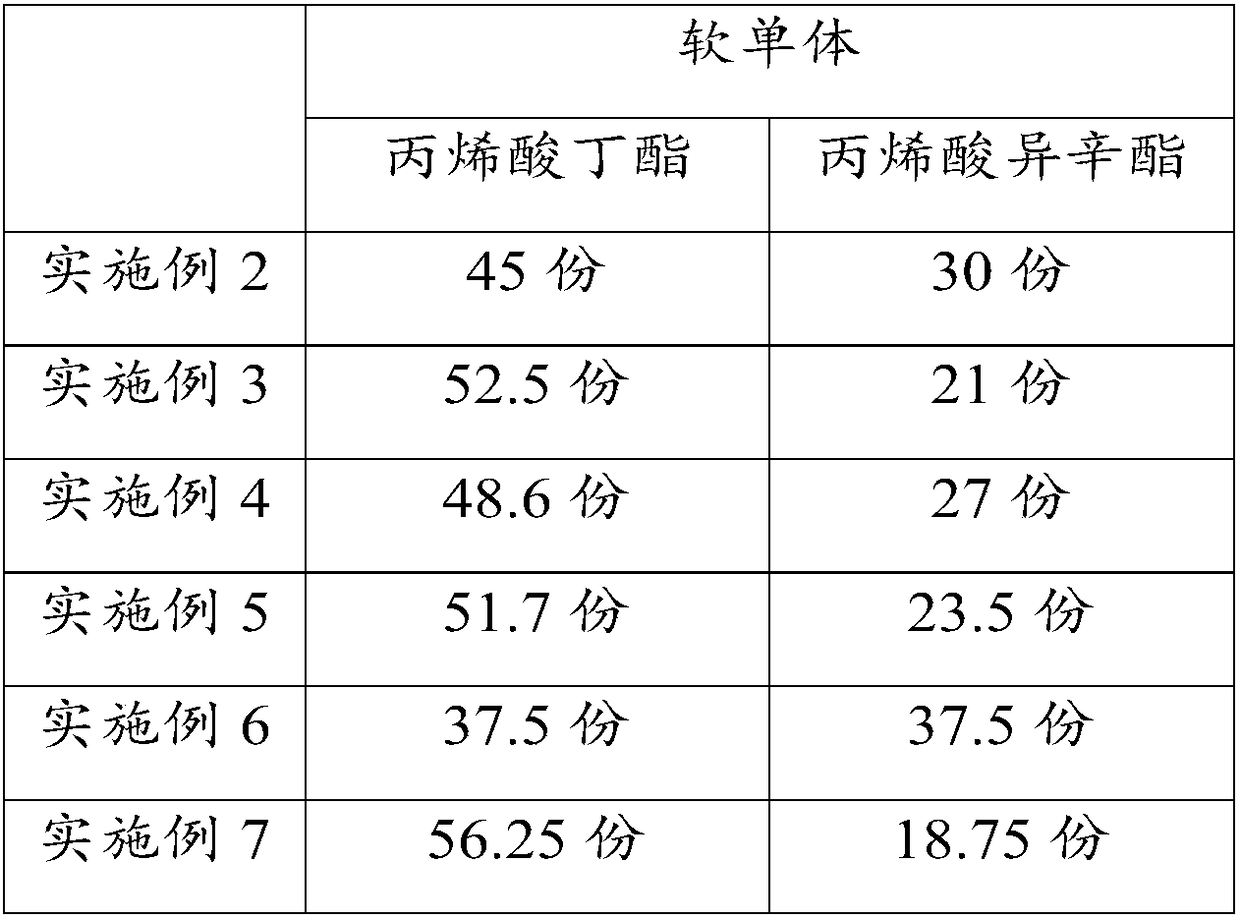

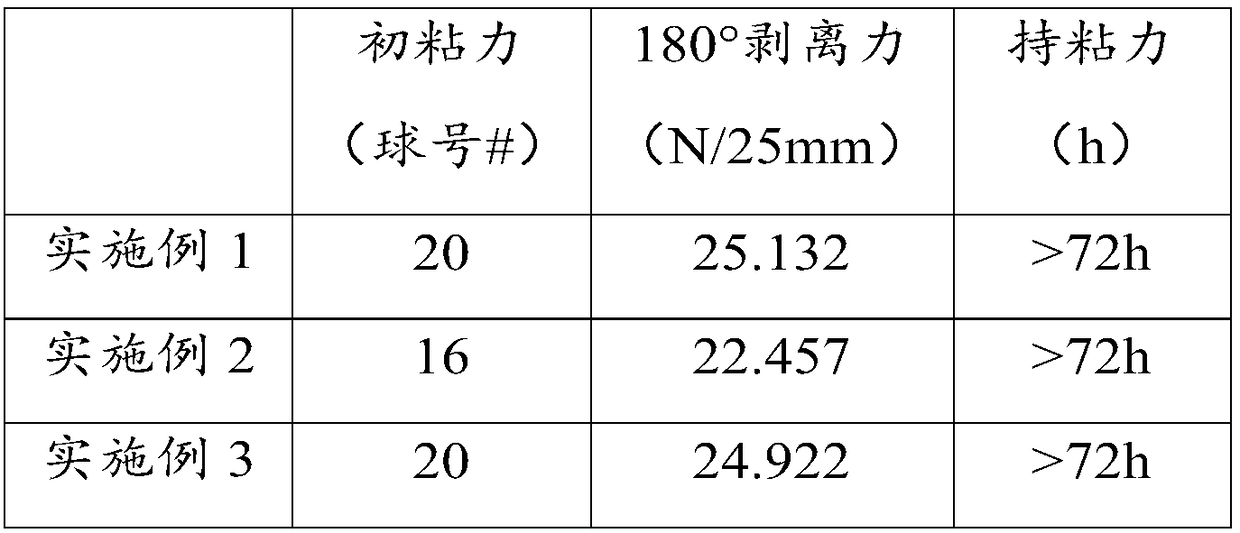

Embodiment 2-7

[0102] The differences between Examples 2-7 and Example 1 are shown in Table 1.

[0103] The difference of table 1 embodiment 2-7 and embodiment 1 soft monomer content

[0104]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stickiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com