Composition, preparation method of heat transfer medium, phase-change refrigeration method of hydrate and phase-change refrigeration system of hydrate

A technology of composition and hydrate accelerator, which is applied in the direction of refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of hydrate accumulation and sedimentation blockage in the use of cooling capacity, and achieve great economic and social value and additional energy consumption Low, energy efficient and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] According to one embodiment of the present invention, based on the total amount of the composition, the content of carbon dioxide is 2-20% by weight, the content of water is 10-60% by weight, and the content of oil-based carrier fluid is 20-80% by weight , the usage amount of the hydrate accelerator and the slurry stabilizer is respectively 0.01-35% by weight and 0.01-4% by weight. Preferably, based on the total amount of the composition, the content of water is 20-50% by weight, the content of oil-based carrier liquid is 21-70% by weight, and the amount of hydrate accelerator and slurry stabilizer is 2-20% respectively. % by weight and 0.1 to 2% by weight. Preferably, relative to the total amount of the composition, the content of carbon dioxide is 5-15% by weight, the content of water is 20-50% by weight, the content of oil-based carrier fluid is 20-70% by weight, the hydrate accelerator and the slurry The dosages of the stabilizers are 4-15% by weight and 0.5-1.5% b...

Embodiment 1

[0078] This example is used to illustrate the preparation method of the heat transfer medium, the hydrate phase-change refrigeration method and the hydrate phase-change refrigeration system of the present invention.

[0079] (1) Preparation of refrigerant working fluid:

[0080] Mix 50 parts by mass of water, 11.76 parts by mass of hydrate accelerator tetrahydrofuran, 0.5 parts by mass of inhibitor sorbitol tristearate and 0.5 parts by mass of surfactant Span 80, and then mix 22.8 parts by mass of No. 5 mineral white oil (commercially purchased from Mojiezuo Petrochemical (Shanghai) Co., Ltd., the brand is MOROKE) is mixed evenly to form a stable oil-water emulsion, which is the refrigerant;

[0081] (2) Phase change refrigeration:

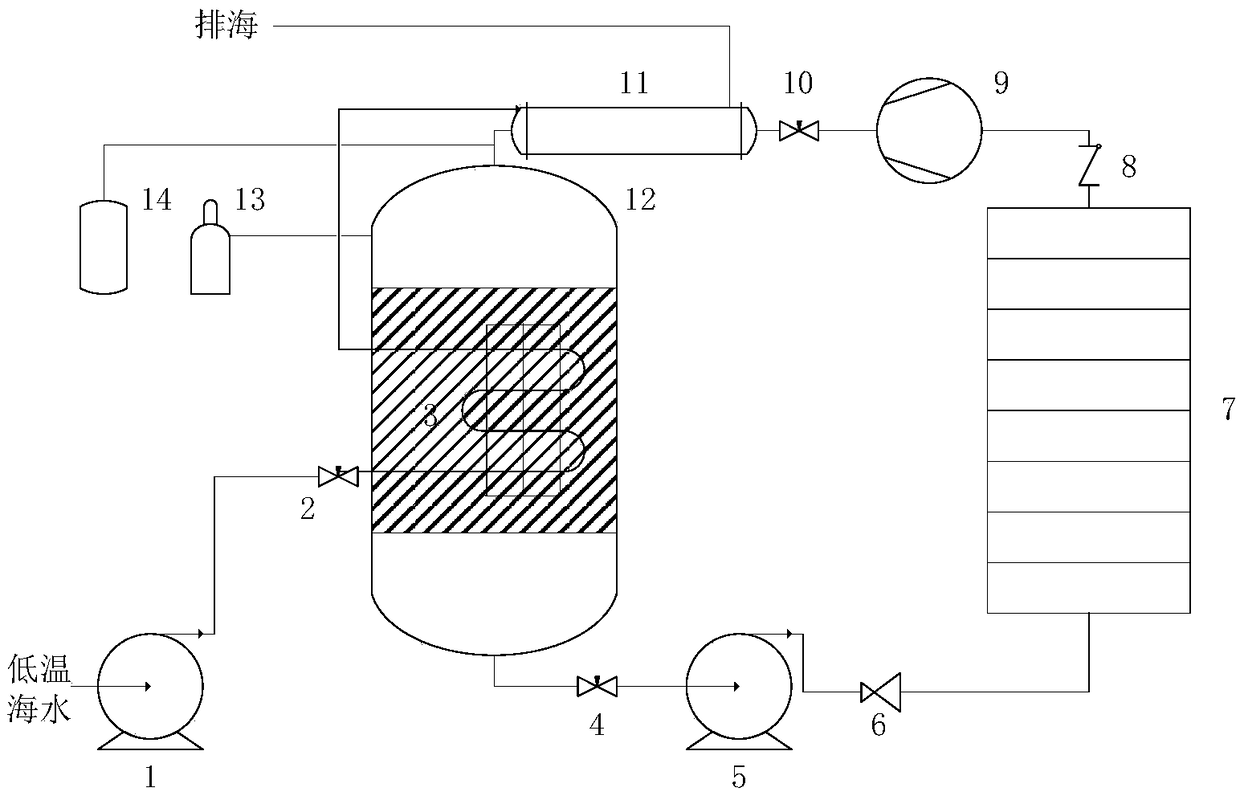

[0082] Add oil-water emulsion figure 1 In the reaction tank of the first heat exchange device 3 of the shown phase-change refrigeration system, then feed 14.44 parts by mass of high-pressure carbon dioxide to fully mix it with the refrigerant to...

Embodiment 2

[0086] This example is used to illustrate the preparation method of the heat transfer medium, the hydrate phase-change refrigeration method and the hydrate phase-change refrigeration system of the present invention.

[0087] (1) Preparation of refrigerant working fluid:

[0088] With the water of 35 mass parts, the hydrate accelerator cyclopentane of 4.0 mass parts, the hydrate accelerator tetrabutylammonium bromide of 4.0 mass parts, the polymerization inhibitor glyceryl monostearate of 0.5 mass parts and 0.5 mass parts 45.9 parts by mass of the surfactant Tween 80 were mixed uniformly, and then 45.9 parts by mass of No. 5 mineral white oil (commercially purchased from Mojiezuo Petrochemical (Shanghai) Co., Ltd., the trade mark was MOROKE / Morunke) were mixed uniformly to form a stable The oil-water emulsion is the refrigerant;

[0089] (2) Phase change refrigeration:

[0090] Add oil-water emulsion figure 1 In the reaction tank of the first heat exchange device 3 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com