A kind of aramid fiber unidirectional moisture-wicking fabric and its preparation method

A unidirectional moisture-wicking, fabric technology, applied in the direction of fabric surface trimming, textile material processing, liquid/gas/vapor textile processing, etc., can solve the working environment that cannot be used with high flame retardant requirements, the requirements of light and thin cannot be achieved, Unable to achieve light weight and other problems, to achieve excellent dimensional stability, high color fastness, and the effect of improving appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

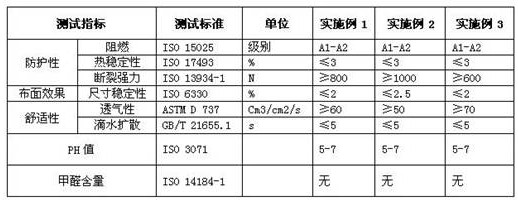

Embodiment 1

[0035] A kind of aramid unidirectional moisture-wicking fabric, which is made of double-ply yarn spun from 90% meta-aramid fiber and 10% silicon-nitrogen flame-retardant viscose fiber through loom weaving. Fabric for light and thin fabrics with moisture guide function, and the weight of the aramid unidirectional moisture guide fabric is 120-200g / m 2 , the width is 1.4-1.6m, preferably 1.5-1.56m.

[0036] Its preparation method comprises the following steps:

[0037] (100) Select the yarn for weaving: select the colored fiber of the stock solution, and use the low-twist spinning process to prepare the 45 / 2 yarn;

[0038] (200) Weaving: Weaving the yarn produced in step (100) according to the specifications of 150gsm, 1 / 1 twill, 75*65, using a PICANOL loom to obtain a gray cloth;

[0039](300) Pre-washing: Put the gray cloth obtained in step (200) in the form of cloth rolls into the jigger for washing, control the washing temperature to 70°C, the speed of cloth rolls to 30rpm,...

Embodiment 2

[0045] An aramid unidirectional moisture-wicking fabric, which is a double-ply yarn spun from 85% meta-aramid fiber, 5% para-aramid fiber and 10% silicon nitrogen flame-retardant viscose fiber through a loom Woven, it is a light and thin fabric with unidirectional moisture-wicking function, and the weight of the aramid unidirectional moisture-wicking fabric is 120-200g / m 2 , the width is 1.4-1.6m, preferably 1.5-1.56m.

[0046] Its preparation method comprises the following steps:

[0047] (100) Select the yarn for weaving: select the colored fiber of the stock solution, and use the low-twist spinning process to prepare the 25 / 2 yarn;

[0048] (200) Weaving: Weaving the yarn produced in step (100) according to the specifications of 200gsm, 1 / 1 twill, 60*45, using a Smit rapier loom to obtain gray cloth;

[0049] (300) Pre-washing: put the gray cloth obtained in step (200) in the form of cloth rolls into the jigger for washing, control the washing temperature to 90°C, the spe...

Embodiment 3

[0055] A kind of aramid unidirectional moisture-wicking fabric, which is made of double-ply yarn spun from 92% meta-aramid fiber and 8% graphene acrylic fiber, and is woven by a loom. Light and thin fabrics with wet function, and the grammage of the aramid unidirectional moisture-wicking fabric is 120-200g / m 2 , the width is 1.4-1.6m, preferably 1.5-1.56m.

[0056] Its preparation method comprises the following steps:

[0057] (100) Select the yarn for weaving: select the colored fiber of the stock solution, and use the low-twist spinning process to prepare the 60 / 2 yarn;

[0058] (200) Weaving: Weaving the yarn produced in step (100) according to the specifications of 120gsm, 2 / 1 twill, 85*65, using THEMA loom to obtain gray cloth;

[0059] (300) Pre-washing: put the gray cloth obtained in step (200) in the form of cloth rolls into the jigger for washing, control the washing temperature to 60°C, the speed of cloth rolls to 20 rpm, and the washing time to 3 hours; after wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com