Double ring reducer

A technology of reducer and ring plate, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of reducing the number of power split transmission flow, increasing the processing difficulty of crankshaft, and easy wear of tapered roller bearings. , to achieve the effect of small deformation, increased stiffness and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

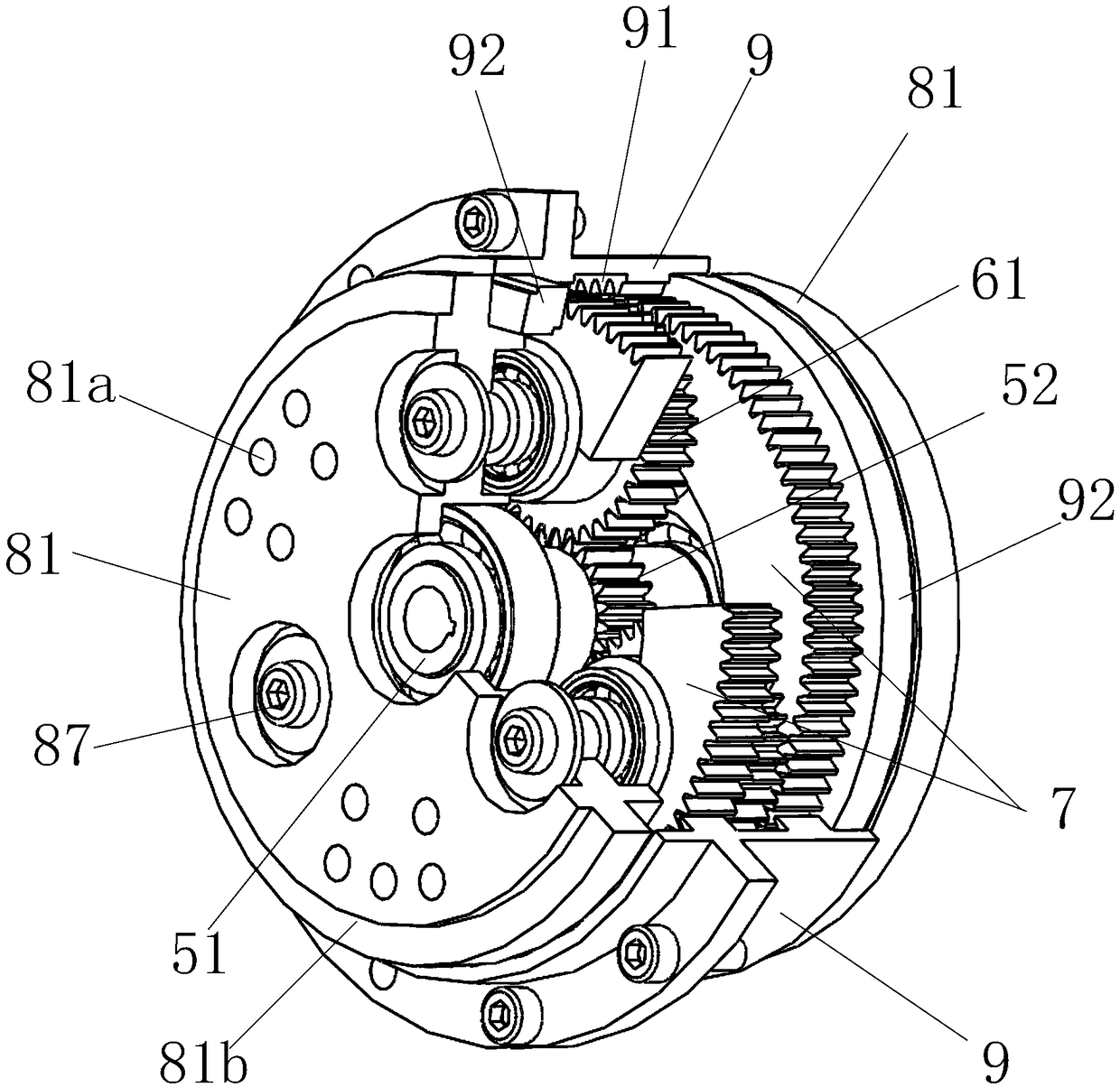

[0040] Such as image 3 and Figure 4 As shown, the present invention provides a double-ring reducer, including a housing 9 with internal teeth 91, a frame 8, a center wheel 5, a cam gear 6, and a ring plate balance wheel 7, wherein the frame 8 and the housing 9 are assembled through bearings 92 connection; the frame 8 includes two end plates 81 and at least one threading rod 82 connected between the two end plates 81, and the two ends of each threading rod 82 are respectively connected with the two end plates 81, so that the frame 8 is a squirrel-cage structure, and the two end plates 81 are supported on the housing 9 through bearings 92, so that the frame 8 can rotate relative to the housing 9, wherein the housing 9 and the two end plates 81 form a closed space, the double-ring reducer All transmission components are located in the enclosed space, wherein the center wheel 5 is arranged in the center of the frame 8, the cam gear 6 is arranged around the center wheel 5, the c...

Embodiment 2

[0058] Figure 8 Shown is a schematic diagram of the structure of the four-flow double-ring reducer of the embodiment of the present invention. The number of convex gears 6 and the number of passing rods 82 are increased to 4 sets, and the rest of the structure is the same as that of Embodiment 1. Under the condition that the external dimensions of the reducer remain unchanged and the transmission ratio remains unchanged, a higher transmission power than that of the three-stream double-ring reducer can be obtained. In other embodiments, it can be 1 stream, 2 streams, 5 streams, 6 streams, etc.

[0059] The double-ring reducer of the present invention has the following advantages:

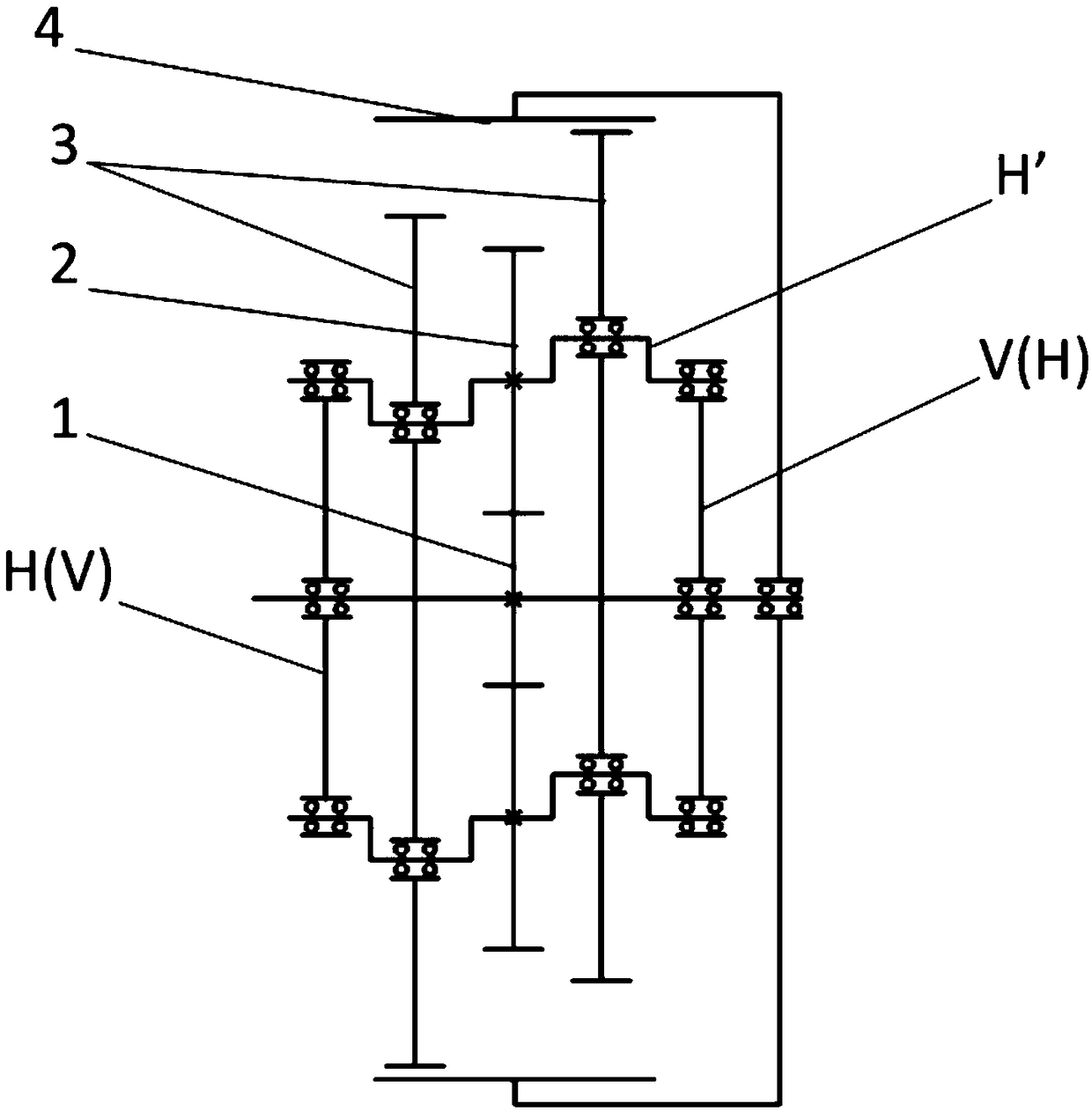

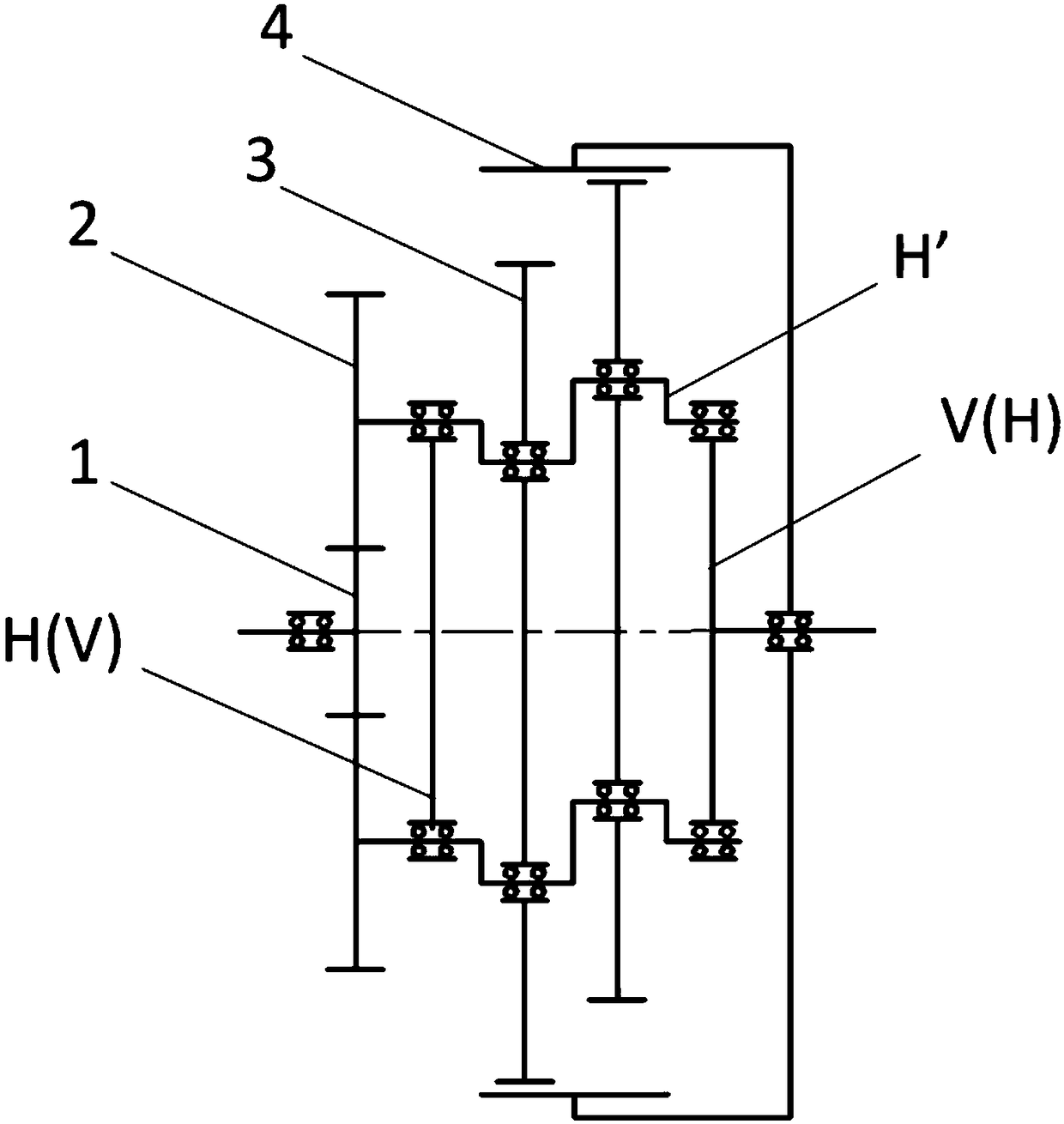

[0060] Compare figure 1 Shown prior art RV reducer with figure 2 As shown, it can be seen from the schematic diagram of the transmission mechanism of the double-ring reducer of the present invention that the planetary gear of the RV reducer is supported by a cantilever on the crankshaft, while th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com