Tungsten-nickel-iron alloy polishing liquid and alloy surface polishing and metallographic preparation method

A technology of tungsten-nickel-iron alloy and polishing liquid, which is applied in the fields of polishing processing and material surface structure determination, can solve the problems of poor surface quality, corrosion, complex metallographic preparation process, etc., and achieves a small height difference between phases and a clear and complete metallographic structure. , The effect of metallographic surface structure is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

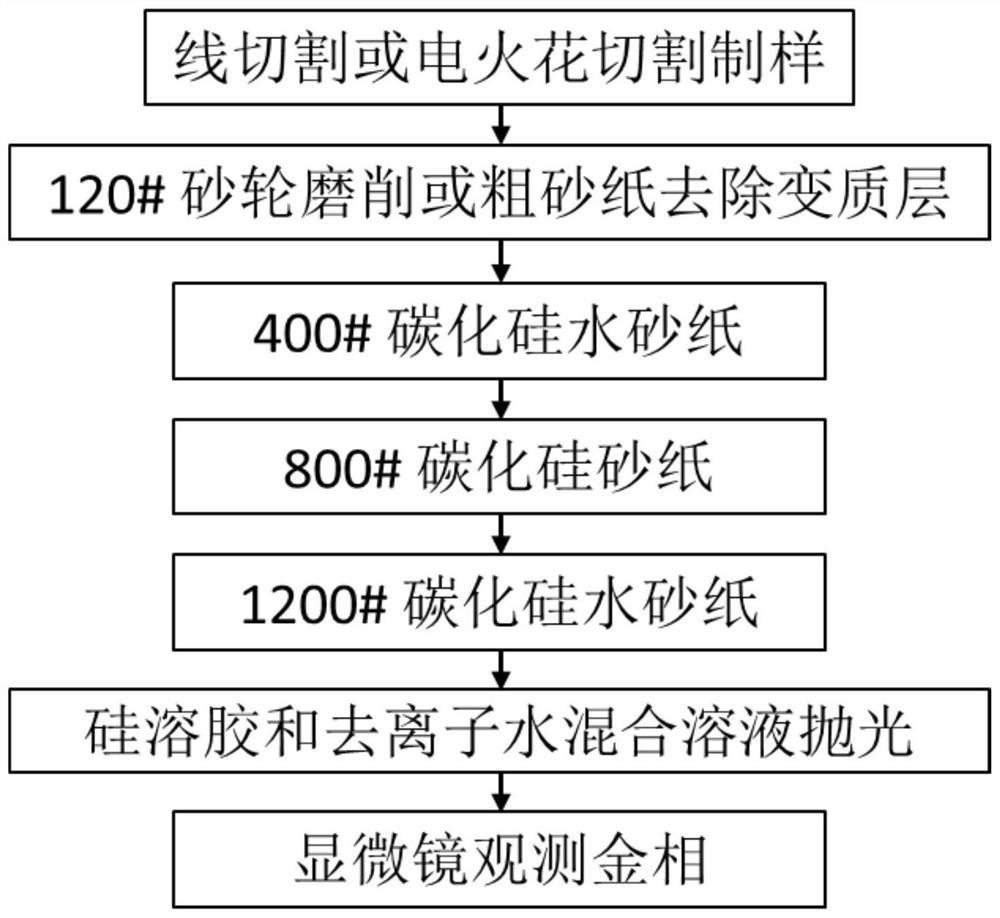

Method used

Image

Examples

Embodiment 1

[0034] A tungsten-nickel-iron alloy chemical mechanical polishing liquid, comprising nano abrasive particles, oxidizing agent, viscosity regulator, pH regulator and deionized water; the content of the nano abrasive particles is 30% of the polishing liquid; the content of the oxidizing agent is polishing 0.01 of the liquid; the viscosity regulator is adjusted according to the actual situation, and the final kinematic viscosity of the polishing liquid reaches 15-20mm 2 / s range; the pH value of the tungsten-nickel-iron alloy chemical mechanical polishing solution is pH 2.5-pH 3.5.

[0035] The nano abrasive particles include colloidal silicon dioxide, and the average abrasive particle diameter is 20-100nm. The oxidizing agent includes citric acid; the viscosity modifier includes glycerin. The pH regulator includes citric acid.

Embodiment 2

[0037] A tungsten-nickel-iron alloy chemical mechanical polishing liquid, comprising nano abrasive particles, oxidizing agent, viscosity regulator, pH regulator and deionized water; the content of the nano abrasive particles is 5.0wt.% of the polishing liquid; the content of the oxidizing agent It is 2.0wt.% of the polishing liquid; the viscosity regulator is adjusted according to the actual situation, and the final viscosity value of the polishing liquid reaches 40-45mm 2 / s range; the pH value of the tungsten-nickel-iron alloy chemical mechanical polishing solution is pH 6.5-pH 7.5, and the specific pH value is determined according to specific procedures.

[0038] The nano-abrasive particles include colloidal aluminum oxide, and the average abrasive particle size is 20-100nm. The oxidizing agent includes oxalic acid; the viscosity regulator includes polyethylene glycol. The pH regulator includes sodium dihydrogen phosphate.

Embodiment 3

[0040] A tungsten-nickel-iron alloy chemical mechanical polishing liquid, comprising nano abrasive particles, oxidizing agent, viscosity regulator, pH regulator and deionized water; the content of the nano abrasive particles is 15wt.% of the polishing liquid; the content of the oxidizing agent is 1.0wt.% of the polishing liquid; the viscosity regulator is adjusted according to the actual situation, and the final viscosity value of the polishing liquid reaches 30-35mm 2 / s range; the pH value of the tungsten-nickel-iron alloy chemical mechanical polishing solution is pH 9.5-pH 10.5, and the specific pH value is determined according to specific procedures.

[0041] The nano-abrasive particles include colloidal aluminum oxide, and the average abrasive particle size is 20-100nm. The oxidizing agent includes oxalic acid; the viscosity regulator includes polyethylene glycol. Described pH adjusting agent comprises citric acid, sodium hydroxide.

[0042] Preparation of tungsten-nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com