A low-temperature-resistant torsion-resistant cable for wind power generation and its preparation method

A torsion-resistant and low-temperature-resistant technology, used in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc. The tensile strength is enhanced, it is not easy to be pulled off, and the effect of reducing line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

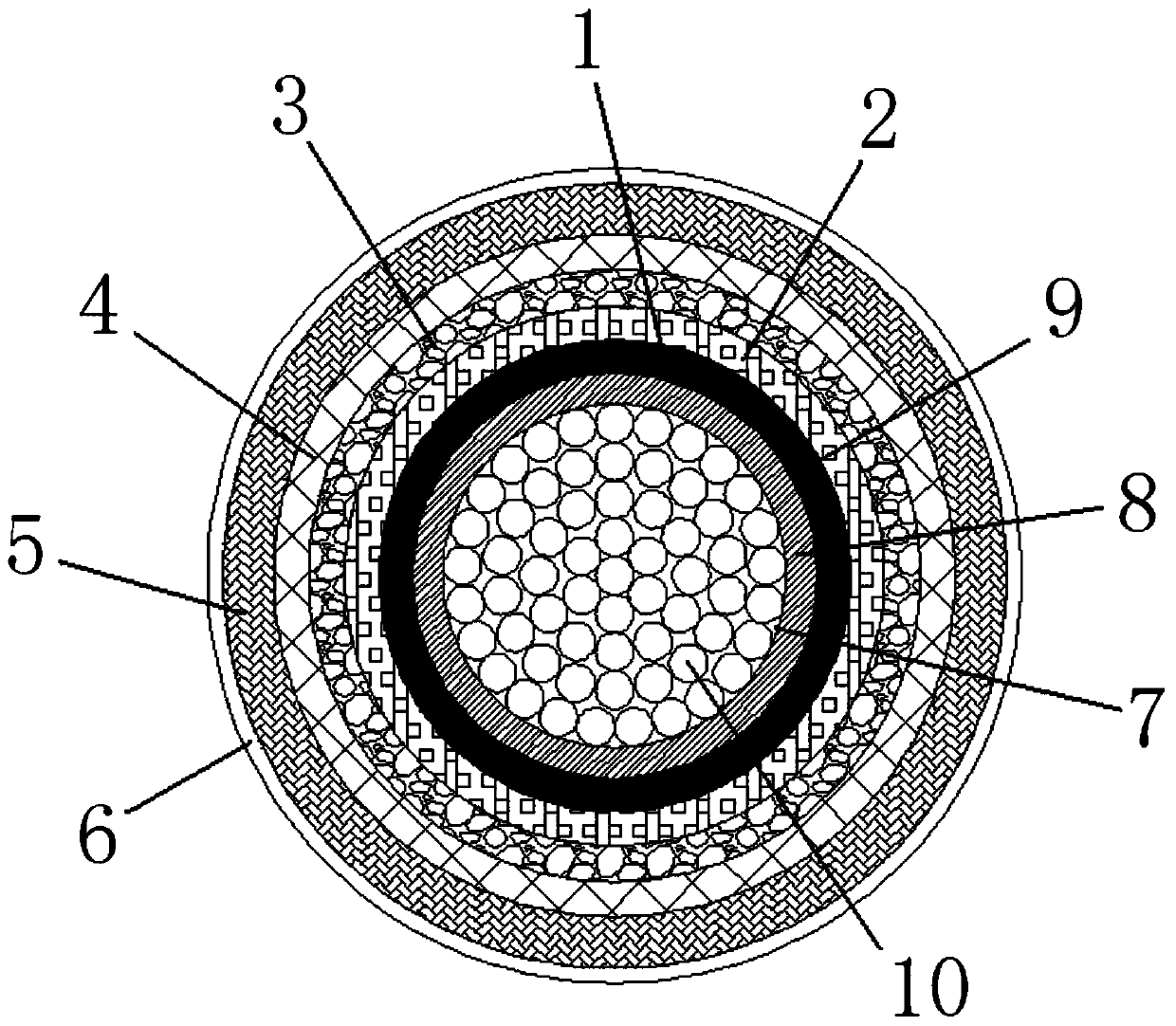

Image

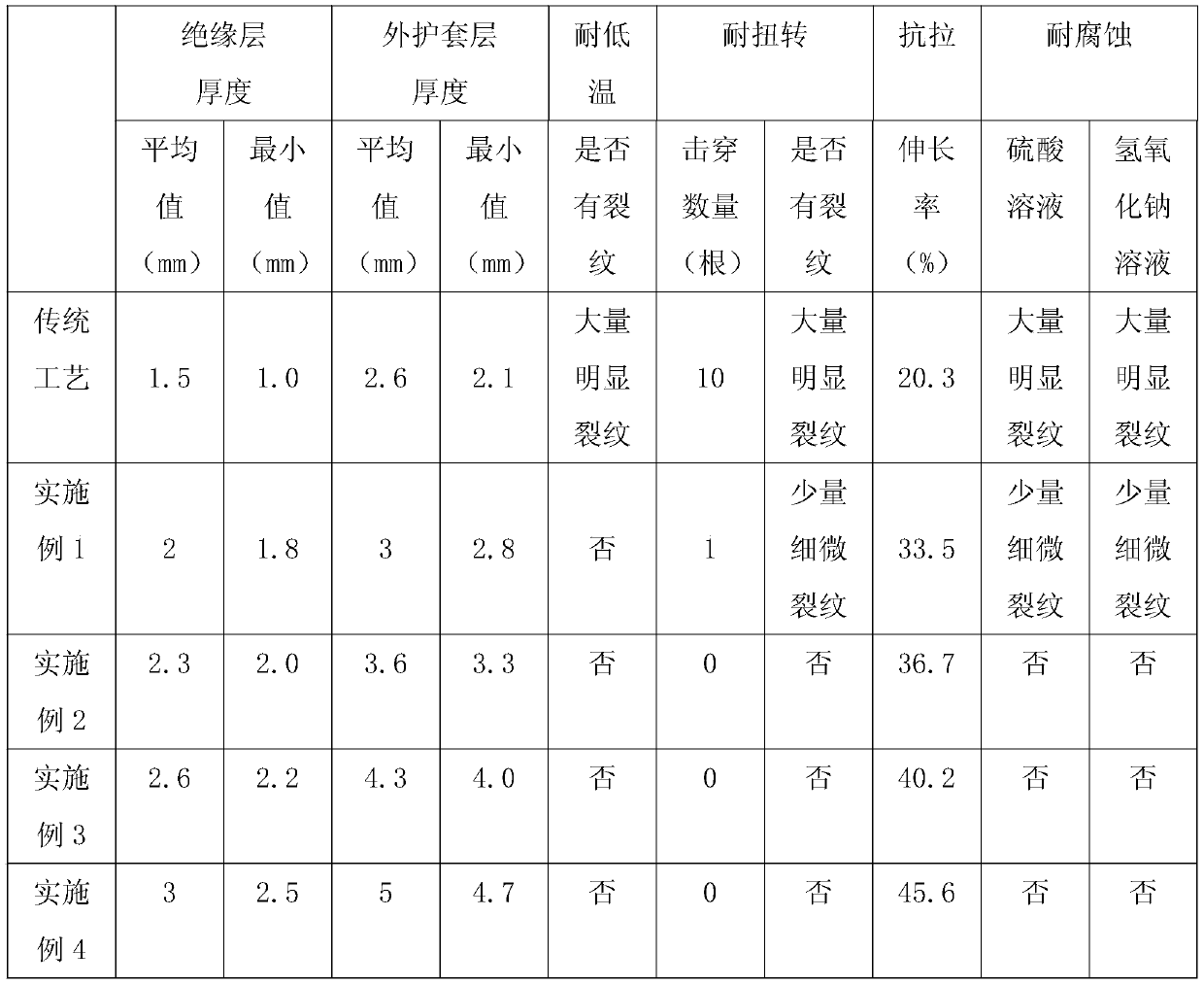

Examples

Embodiment 1

[0058] Embodiment 1 discloses a method for preparing a low-temperature-resistant torsion-resistant cable for wind power generation, including the following preparation steps:

[0059] Step a: wire drawing annealing

[0060] Use a wire drawing machine to stretch the copper rod to obtain copper wire. The speed of the wire drawing machine is 1450-1560r / min, and the diameter of the copper wire is 1-2mm. Then, anneal the copper wire:

[0061] The specific steps of annealing treatment include:

[0062] Put the copper wire into the heating furnace and seal the heating furnace, then raise the temperature in the heating furnace to 500-600°C and keep it warm for 4-5 hours, then take the copper wire out of the heating furnace and put it into a vacuum environment to cool naturally to At room temperature, put the copper wire into the copper antioxidant and soak it for 5-10 minutes, then take it out for drying treatment, and obtain the conductor;

[0063] Step b: Preparation of guide core...

Embodiment 2

[0089] Embodiment 2 discloses a method for preparing a low-temperature-resistant torsion-resistant cable for wind power generation, including the following preparation steps:

[0090] Step a: wire drawing annealing

[0091] Use a wire drawing machine to stretch the copper rod to obtain copper wire. The speed of the wire drawing machine is 1450-1560r / min, and the diameter of the copper wire is 1-2mm. Then, anneal the copper wire:

[0092] The specific steps of annealing treatment include:

[0093] Put the copper wire into the heating furnace and seal the heating furnace, then raise the temperature in the heating furnace to 500-600°C and keep it warm for 4-5 hours, then take the copper wire out of the heating furnace and put it into a vacuum environment to cool naturally to At room temperature, put the copper wire into the copper antioxidant and soak it for 5-10 minutes, then take it out for drying treatment, and obtain the conductor;

[0094] Step b: Preparation of guide core...

Embodiment 3

[0120] Embodiment 3 discloses a method for preparing a low-temperature-resistant torsion-resistant cable for wind power generation, including the following preparation steps:

[0121] Step a: wire drawing annealing

[0122] Use a wire drawing machine to stretch the copper rod to obtain copper wire. The speed of the wire drawing machine is 1450-1560r / min, and the diameter of the copper wire is 1-2mm. Then, anneal the copper wire:

[0123] The specific steps of annealing treatment include:

[0124] Put the copper wire into the heating furnace and seal the heating furnace, then raise the temperature in the heating furnace to 500-600°C and keep it warm for 4-5 hours, then take the copper wire out of the heating furnace and put it into a vacuum environment to cool naturally to At room temperature, put the copper wire into the copper antioxidant and soak it for 5-10 minutes, then take it out for drying treatment, and obtain the conductor;

[0125] Step b: Preparation of guide core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com