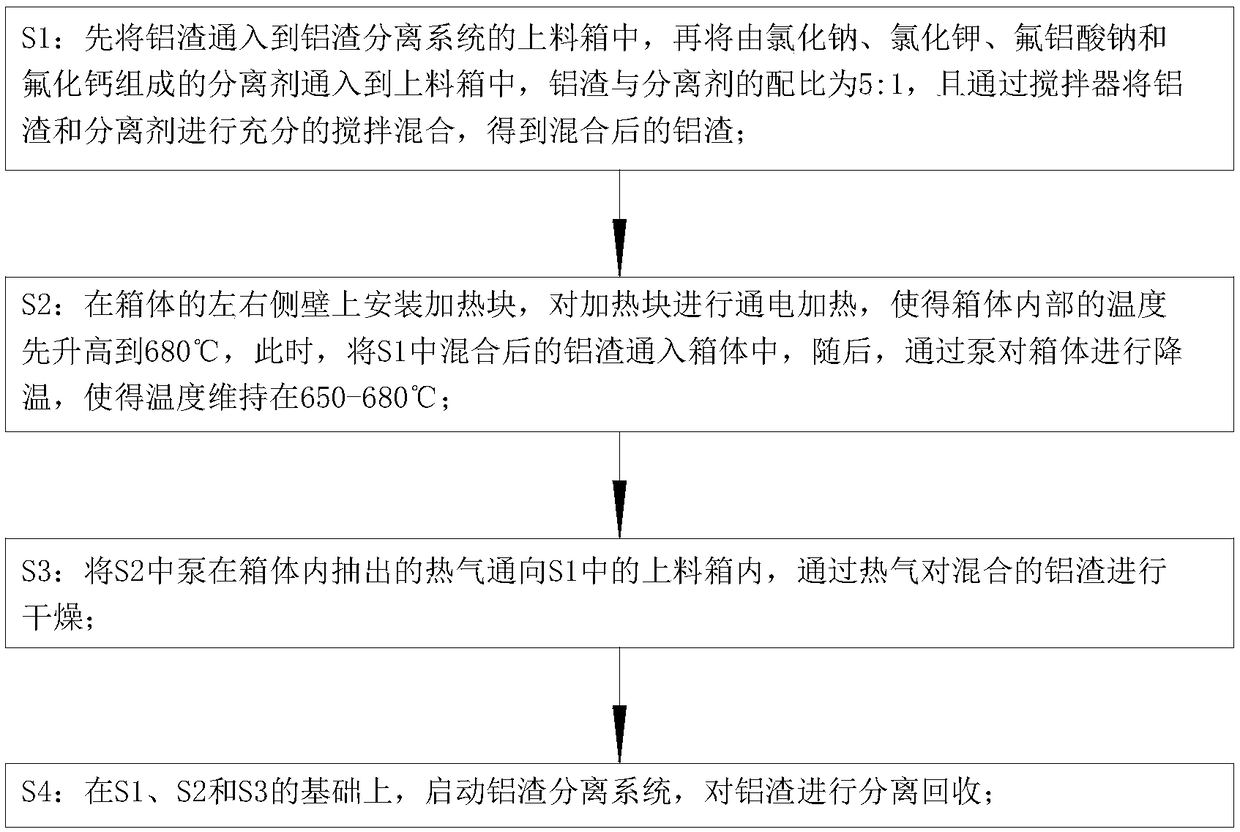

High-efficiency aluminum slag recovery method

A recycling method and technology for aluminum slag, which can be used in the improvement of process efficiency, grain treatment and other directions, can solve the problems of low efficiency of separation and recovery of aluminum slag, and achieve the effect of easy promotion, wide application range and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

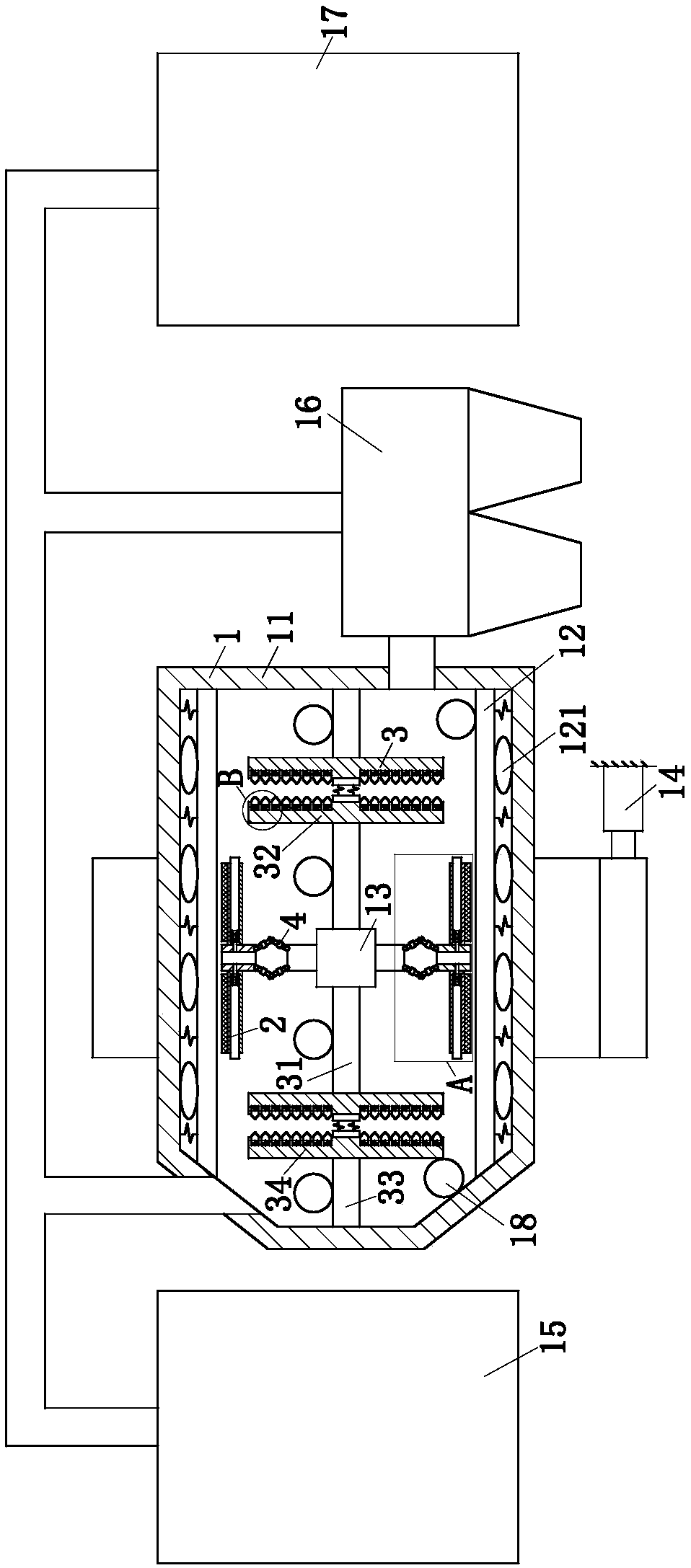

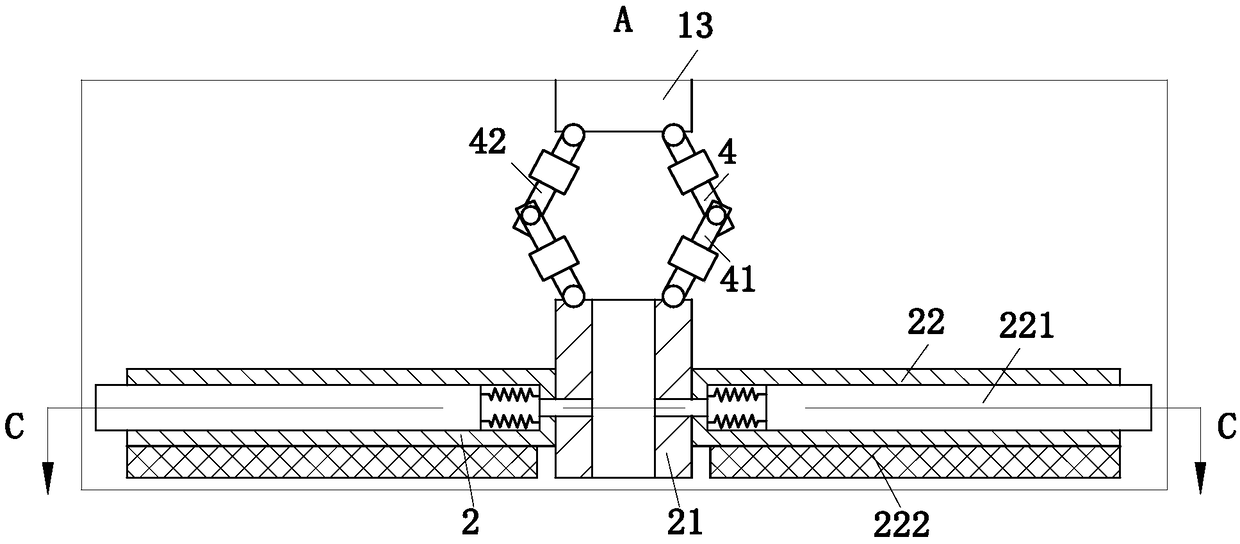

[0039] As an embodiment of the present invention, a number of No. 1 grooves are provided on the grinding and smashing disk 22, and the No. 1 grooves are circumferentially distributed on the grinding and smashing disk 22, and a crushing rod 221 is provided on the No. 1 groove; the crushing rod 221 It is fixedly connected to the No. 1 groove by a spring, and the crushing rod 221 is threadedly connected to the inner wall of the No. 1 groove. The gas generated during the expansion and contraction of the No. 1 double-head cylinder 41 and the No. 2 double-head cylinder 42 acts on the crushing rod 221 to make the crushing The rod 221 is unscrewed to crush the aluminum slag. In the present invention, by setting the breaking rod 221, on the one hand, the gas produced by the No. 1 double-head cylinder 41 and the No. 2 double-head cylinder 42 is utilized, thereby improving the utilization rate of resources; The gas produced by 41 and No. 2 double-head cylinder 42 acts on the crushing rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com