Hydrogen fuel cell automobile thermal management system

A thermal management system and fuel cell technology, applied in fuel cells, electric vehicles, power management, etc., can solve the problems of low heat exchange in the main circulation loop, inability to control the amount of coolant circulation, and uncontrollable coolant conductivity, etc. To achieve the effect of good heat dissipation, controllable conductivity, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

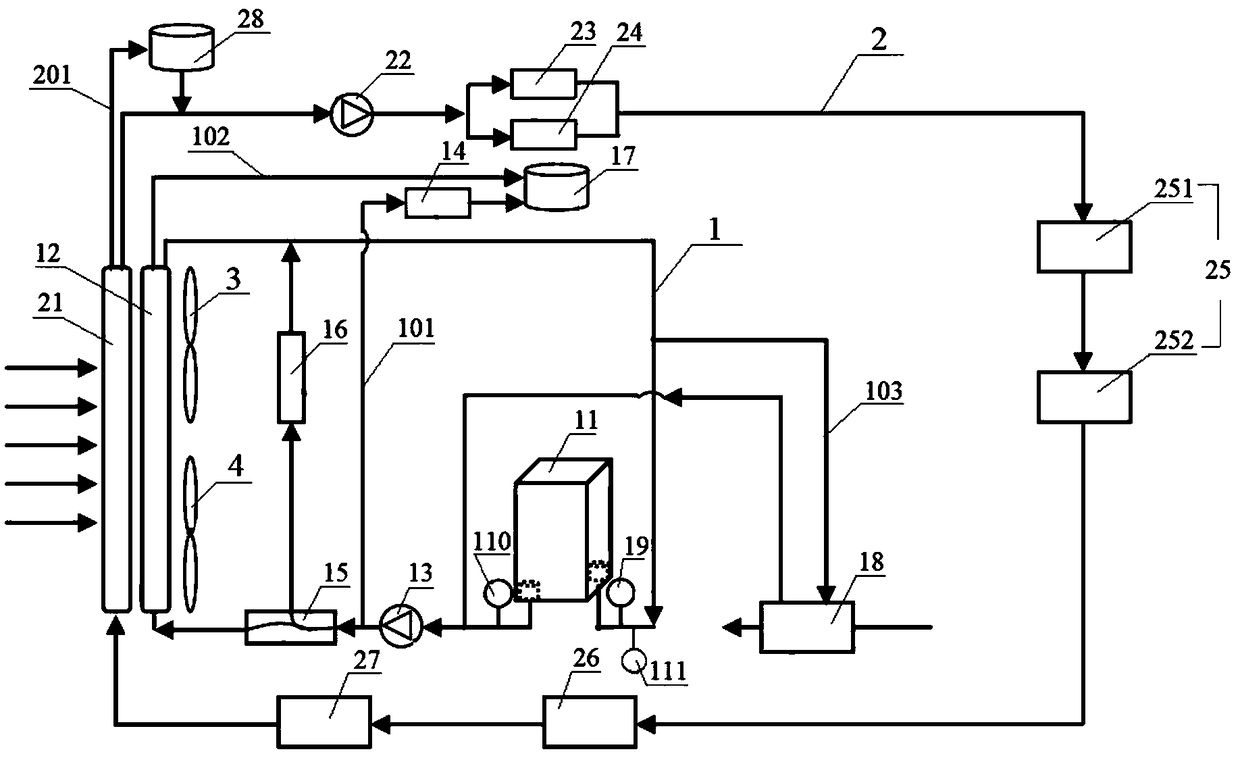

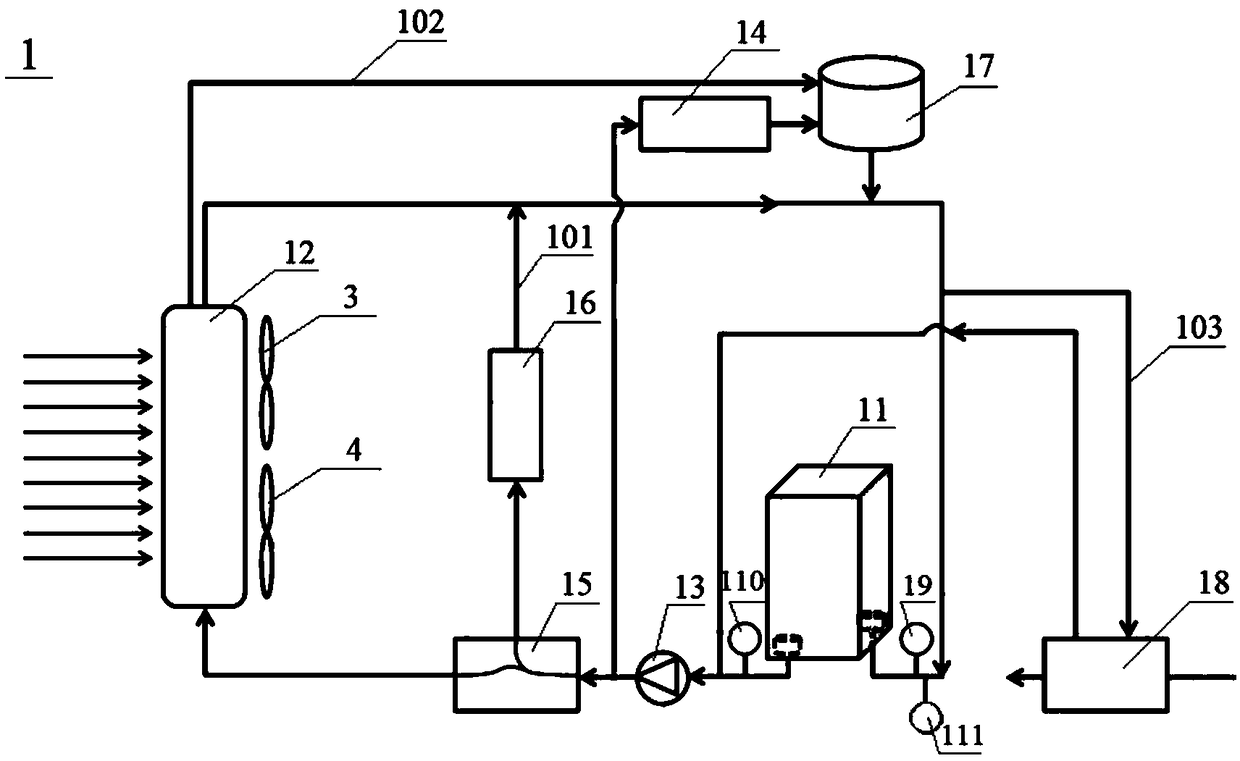

[0127] This embodiment provides a thermal management system for a hydrogen fuel cell vehicle, including a first cooling circuit 1 and a second cooling circuit 2 .

[0128] For the first cooling circuit 1, the first radiator 12, the first temperature sensor 19, the pressure sensor 111, the 36kW hydrogen fuel stack 11, the second temperature sensor 110, the circulation pump 13, the After the thermostat 15 is connected in series to form the main circulation loop, the heater 16, the first branch 101 provided with the deionizer 14, the second branch 102 provided with the first expansion tank 17, and the intercooler 18 are respectively installed. The third branch 103 of . Wherein, the ion exchange capacity of the deionizer 14 is 200meq / g, and the cooling liquid circulation volume of the first branch 101 is 5% of the cooling liquid circulation volume of the main circulation loop.

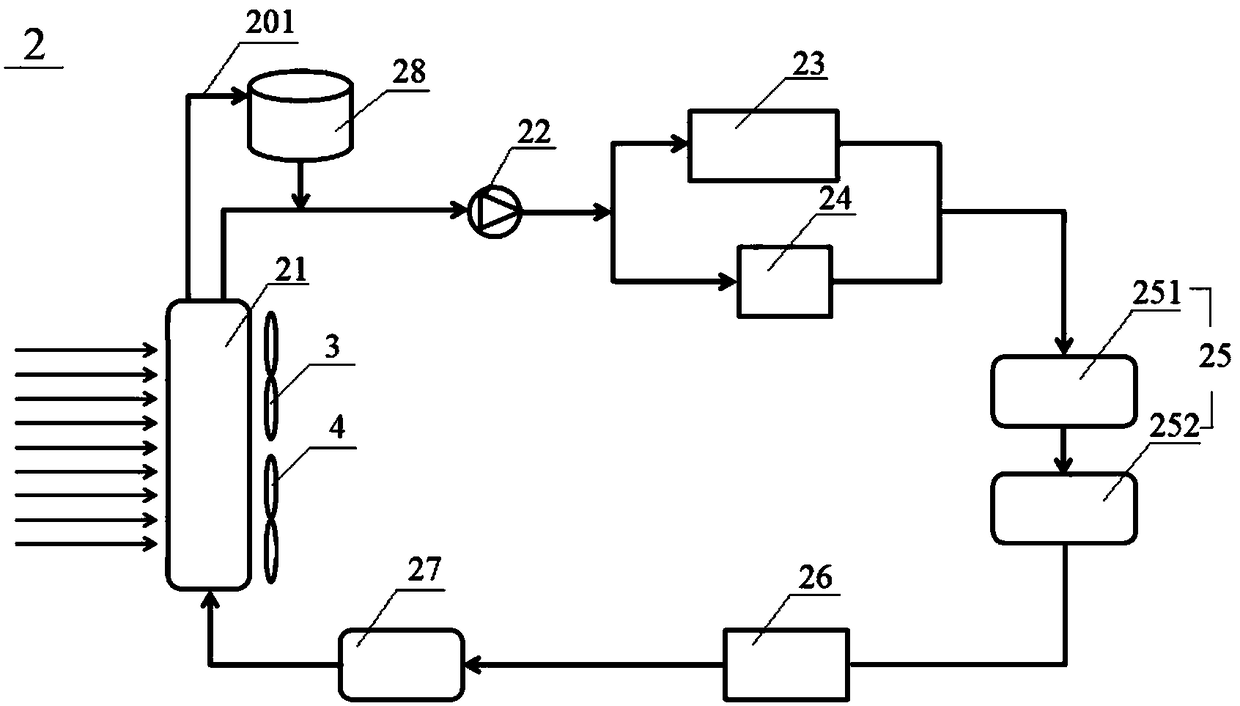

[0129] For the second cooling circuit 2, the second radiator 21, electronic water pump 22, air compres...

Embodiment 2

[0137]This embodiment provides a thermal management system for a hydrogen fuel cell vehicle, including a first cooling circuit 1 and a second cooling circuit 2 .

[0138] For the first cooling circuit 1, the first radiator 12, the first temperature sensor 19, the pressure sensor 111, the 36kW hydrogen fuel stack 11, the second temperature sensor 110, the circulation pump 13, the After the thermostat 15 is connected in series to form the main circulation loop, the heater 16, the first branch 101 provided with the deionizer 14, the second branch 102 provided with the first expansion tank 17, and the intercooler 18 are respectively installed. The third branch 103 of . Wherein, the ion exchange capacity of the deionizer 14 is 330meq / g, and the cooling liquid circulation volume of the first branch 101 is 5% of the cooling liquid circulation volume of the main circulation loop.

[0139] For the second cooling circuit 2, the second radiator 21, electronic water pump 22, air compress...

Embodiment 3

[0147] This embodiment provides a thermal management system for a hydrogen fuel cell vehicle, including a first cooling circuit 1 and a second cooling circuit 2 .

[0148] For the first cooling circuit 1, the first radiator 12, the first temperature sensor 19, the pressure sensor 111, the 36kW hydrogen fuel stack 11, the second temperature sensor 110, the circulation pump 13, the After the thermostat 15 is connected in series to form the main circulation loop, the heater 16, the first branch 101 provided with the deionizer 14, the second branch 102 provided with the first expansion tank 17, and the intercooler 18 are respectively installed. The third branch 103 of . Wherein, the ion exchange capacity of the deionizer 14 is 490meq / g, and the cooling liquid circulation volume of the first branch 101 is 5% of the cooling liquid circulation volume of the main circulation loop.

[0149] For the second cooling circuit 2, the second radiator 21, electronic water pump 22, air compres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com