Method for producing nickel sulfate solution by taking nickel oxide as raw material,

A technology of nickel oxide and nickel sulfate, applied in the direction of nickel sulfate, etc., which can solve the problems of difficult nickel oxide treatment, high acidity, and difficulty in reducing pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

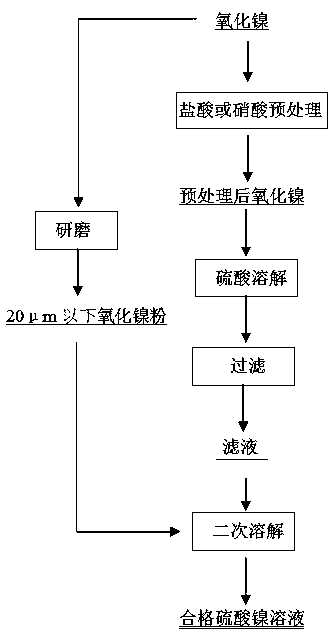

Method used

Image

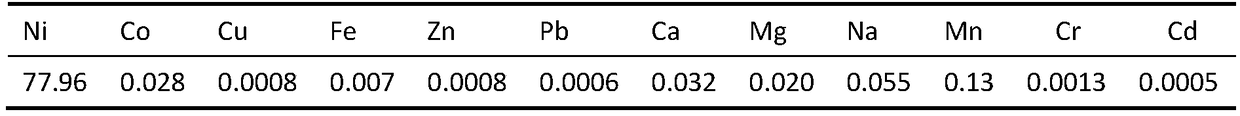

Examples

Embodiment 1

[0028] a. Hydrochloric acid pretreatment of nickel oxide

[0029] Hydrochloric acid with a hydrogen ion concentration of 10mol / L is used to pretreat nickel oxide. The pretreatment temperature is 95°C, the liquid-solid ratio of hydrochloric acid to nickel oxide is 4:1 (the volume of hydrochloric acid is 2.4L, and the weight of nickel oxide is 0.6kg), and the treatment time is 10 minutes. Solid separation, the obtained solid was washed with pure water at room temperature, the liquid-solid ratio of pure water to the obtained solid was 4:1 (the volume of pure water was 2L, and the weight of nickel oxide was 0.5kg), and the washing times were 3 times.

[0030] b. Sulfuric acid dissolves nickel oxide

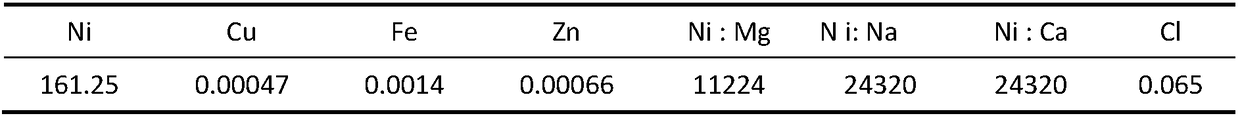

[0031] Dissolve the nickel oxide obtained in step a with a hydrogen ion concentration of 5.5 mol / L sulfuric acid, the reaction temperature is 90 °C, the liquid-solid ratio is 5:1 (the volume of sulfuric acid is 2.5 L, the weight of nickel oxide is 0.5 kg), and the solid-liquid separat...

Embodiment 2

[0038] a. Hydrochloric acid pretreatment of nickel oxide

[0039] Hydrochloric acid with a hydrogen ion concentration of 7mol / L is used to pretreat nickel oxide. The pretreatment temperature is 85°C, the liquid-solid ratio of hydrochloric acid to nickel oxide is 3:1 (the volume of hydrochloric acid is 1.8L, and the weight of nickel oxide is 0.6kg), and the treatment time is 5 minutes. Solid separation, the obtained solid was washed with pure water at room temperature, the liquid-solid ratio of washing water to nickel oxide was 3:1 (the volume of pure water was 1.71L, and the weight of nickel oxide was 0.57kg), and the number of washings was 4 times.

[0040] b. Sulfuric acid dissolves nickel oxide

[0041] Dissolve nickel oxide with sulfuric acid, the hydrogen ion concentration is 4.5mol / L, the reaction temperature is 85°C, the sulfuric acid volume is 2.3L, the nickel oxide weight is 0.57kg, the hydrogen ion concentration is 0.88mol / L, and the nickel ion is 106.23g / L by solid-...

Embodiment 3

[0048] a. Nitric acid pretreatment of nickel oxide

[0049] Nitric acid with an initial hydrogen ion concentration of 8mol / L, the pretreatment temperature is 75°C, the liquid-solid ratio of nitric acid to nickel oxide is 1:1 (acid volume 1L, nickel oxide weight 1kg), pretreatment time 8min, liquid-solid separation, and solid Wash with pure water at room temperature, the liquid-solid ratio of washing water to nickel oxide is 1:1 (the volume of pure water is 1L, the weight of nickel oxide is 1kg), and the number of washings is 6 times.

[0050] b. Sulfuric acid dissolves nickel oxide

[0051] Dissolve nickel oxide in sulfuric acid with a hydrogen ion concentration of 3mol / L, the reaction temperature is 75°C, the volume of sulfuric acid is 1.9L, the weight of nickel oxide is 0.95kg, and the solid-liquid separation obtains nickel sulfate with a hydrogen ion concentration of 0.58mol / L and a nickel ion of 71g / L solution.

[0052] c. Secondary dissolution of nickel oxide powder

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com