Low-temperature thermal barrier powder coating and preparation method thereof

A powder coating, low-temperature heat technology, applied in powder coating, epoxy resin coating, coating, etc., can solve the problems that powder coating cannot be sprayed with heat-sensitive materials, low curing temperature, short curing time, etc., and achieve excellent blooming Performance and mechanical properties, effect of low curing temperature and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

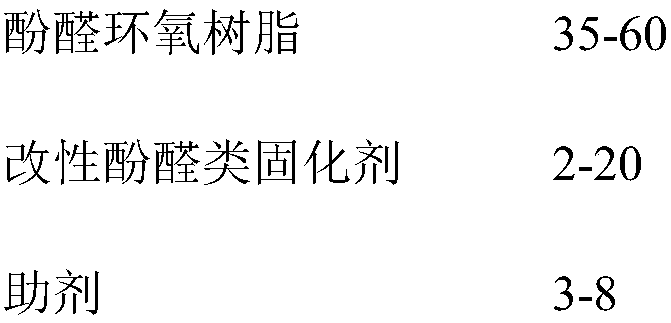

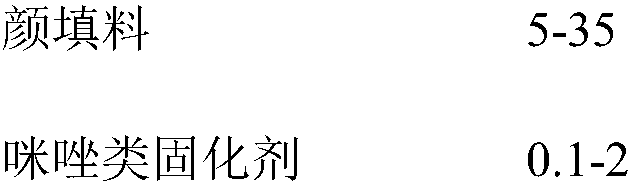

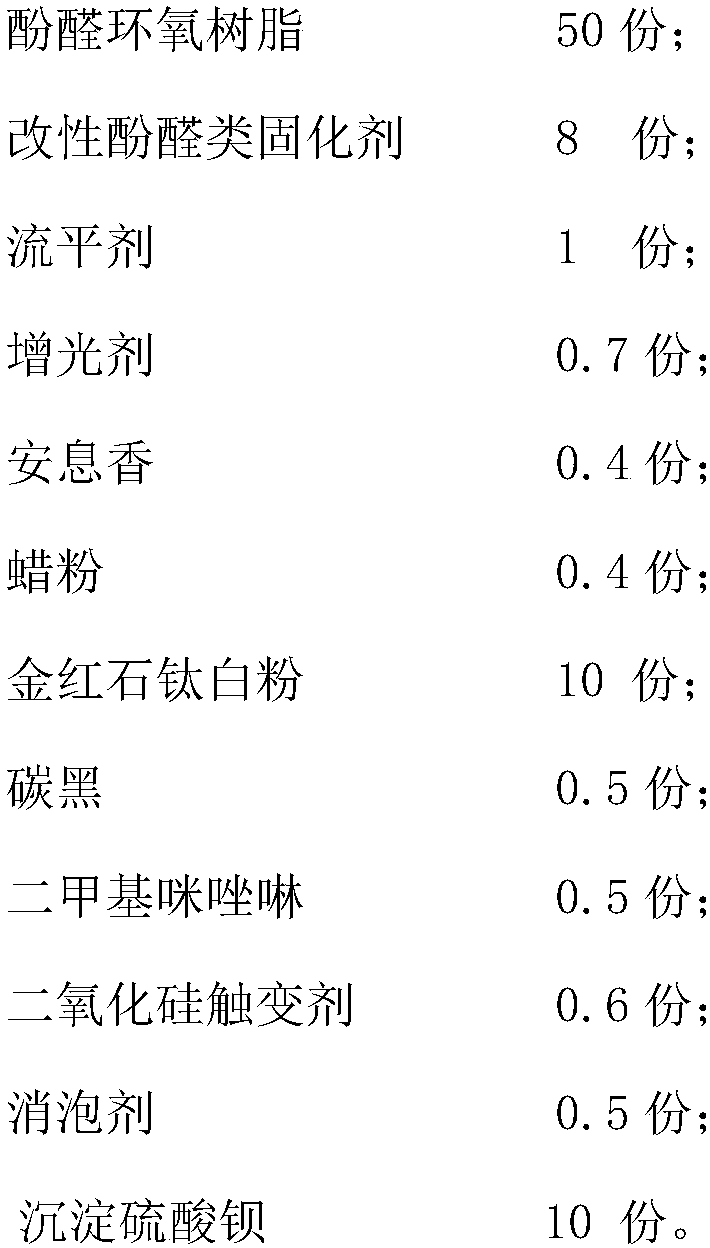

[0028] One, weigh each component of corresponding quality according to the formula of following each embodiment: the measurement unit of each component in each embodiment formula is kg.

[0029]

[0030]

[0031] The powder coating components of the above-mentioned Examples 1 to 9 were prepared according to the following steps: (1) premixing each component; (2) mixing uniformly in the crushing cylinder; (3) melt extruding (4) cooling by air cooler; (5) fine grinding by SCM mill; (6) packing. Wherein the melting temperature of the twin-screw extruder in the step (2) is set at 80-90°C. The powder coatings numbered P-1, P-2,,,,, P-9 were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com