Cold crucible directional solidification method for refining lamellar structure of TiAl alloy

A directional solidification, cold crucible technology, applied in the field of TiAl alloy processing, can solve problems such as coarsening, and achieve the effects of refining lamellar structure, increasing cooling rate, and improving room temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment 1: This embodiment records a cold crucible directional solidification method for refining TiAl alloy lamellar structure, and the method includes the following steps:

[0027] Step 1: preparing an alloy ingot whose composition is Ti-47Al-2Nb-2Cr-0.2C (unless otherwise specified, the composition is atomic percentage);

[0028] Step 2: processing the Ti-47Al-2Nb-2Cr-0.2C alloy ingot into a round bar for cold crucible directional solidification experiments;

[0029] Step 3: In the multi-functional cold crucible electromagnetically confined precise forming directional solidification equipment (quoted from the application number: 2018107732776), the round rod used for the directional solidification experiment is prepared into a TiAl intermetallic compound directional solidification sample;

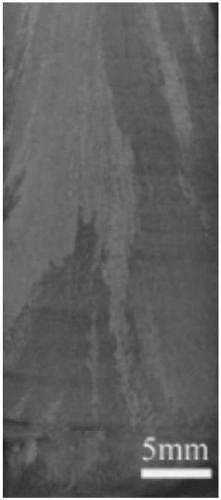

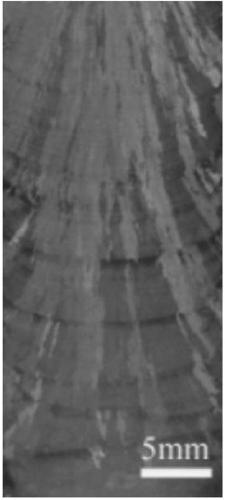

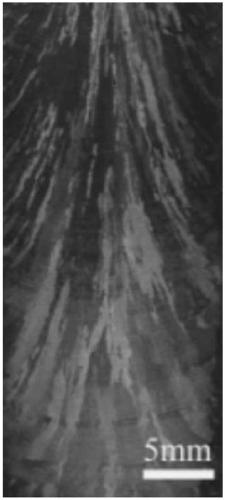

[0030] Step 4: If figure 1 As shown, the directional solidification experiment was carried out on the TiAl intermetallic compound directional solidification sample, a...

specific Embodiment approach 2

[0032] Specific embodiment two: a cold crucible directional solidification method for refining TiAl alloy lamellar structure described in specific embodiment one, in step one, Ti-47Al-2Nb-2Cr-0.2C alloy is prepared by vacuum induction melting Ingot casting, the specific steps are as follows: according to the alloy composition, put titanium sponge, aluminum block, aluminum niobium master alloy, chromium sheet and C powder into a vacuum induction melting furnace (a small vacuum induction melting furnace of Consarc Company in the United States), and evacuate to 2.0 ×10 -3 ~2.5×10 -3 mbar, increase the smelting power to 150-160kW at a rate of 8-10kW / min and stop increasing the power, then smelt at a constant power for 3-5min to obtain an alloy melt, and then pour the melt into a furnace preheated to 350-400°C In the metal casting mold, a Ti-47Al-2Nb-2Cr-0.2C alloy ingot is obtained, and is naturally cooled to room temperature with the furnace.

specific Embodiment approach 3

[0033] Specific embodiment three: the cold crucible directional solidification method of a kind of refinement TiAl alloy lamellar structure described in specific embodiment one, in step two, adopt electric spark numerical control cutting machine tool (the numerical control DK7780 of Ningbo Haishu Zhongyuan Machine Tool Co., Ltd. fast walk wire machine tool) to process the Ti-47Al-2Nb-2Cr-0.2C alloy ingot into a round bar for directional solidification experiments, the wire speed of the EDM CNC cutting machine tool is 0.1m / s, and the diameter of the round bars for directional solidification experiments is 20mm.

[0034] Embodiment 4: A cold-crucible directional solidification method for refining the lamellar structure of TiAl alloy described in Embodiment 1. In step 4, a PtRh30-PtRh6 thermocouple with a diameter of Ф0.15 mm is inserted into the solid phase of the TiAl alloy , through the multi-channel temperature tester (JK-32U multi-channel temperature tester produced by Xingt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com