Explosion-activated type downhole annulus blowout preventer

A technology of blowout preventer and annulus, which is applied to wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc. It can solve problems such as delayed response of blowout prevention operations, engineering hidden dangers, high risks, etc., and achieve Fast and reliable sealing and unsealing operations, ensuring safety and reliability, reliable and fast information transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

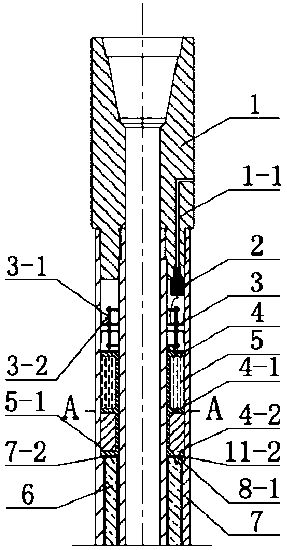

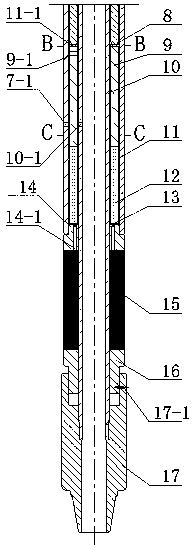

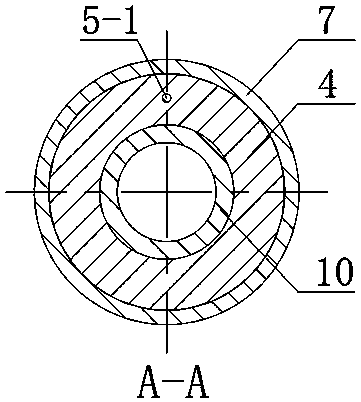

[0025] Example 1: if figure 1As shown, an explosion-activated downhole annular blowout preventer includes an upper joint (1), a pressure sensor (2), a console frame (3), a fixed cylinder (4), a battery (5), an explosive (6), Outer Sleeve (7), Explosion Shell (8), Piston (9), Center Tube (10), Hydraulic Shell (11), Hydraulic Oil (12), Check Valve (13), Rubber Tube Upper Joint (14), rubber cartridge (15), lower joint (16) and lower joint (17) of the rubber cartridge; upper joint (1) and lower joint (17) are arranged at both ends of the central cylinder (10), and the central cylinder (10 ) and the upper and lower joints (1, 17) are fixed by threaded connection, the upper joint (1) is provided with a mud pressure monitoring channel (1-1), and the outer sleeve (7) and the upper joint (1) adopt the most convenient Threaded connection. The explosion-activated downhole annular blowout preventer adopts the piston (9) for power transmission, and squeezes the hydraulic oil into the rub...

example 2

[0026] Example 2: Based on the device of Example 1, the blowout prevention method of the explosion-activated downhole blowout preventer is as follows.

[0027] 1. When an overflow occurs, the high-pressure fluid in the formation enters the drill string through the drill bit and flows upward, so that the blowout prevention check valve at the drill bit is closed to block the inner channel of the drill string. At the same time, the high-pressure fluid in the annulus of the wellbore passes through The pressure monitoring channel of the joint on the downhole blowout preventer, and the overflow phenomenon is monitored by the pressure sensor, and blowout prevention measures must be taken at this time.

[0028] 2. After the overflow signal is received by the signal receiving processor, it is passed to the decoder for translation and encoding, and then passed to the control board to control the ignition device to detonate the explosives. After the explosion, on the one hand, a severe a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com