New method for preparing hydrophilic polyurethane silver ion dressing

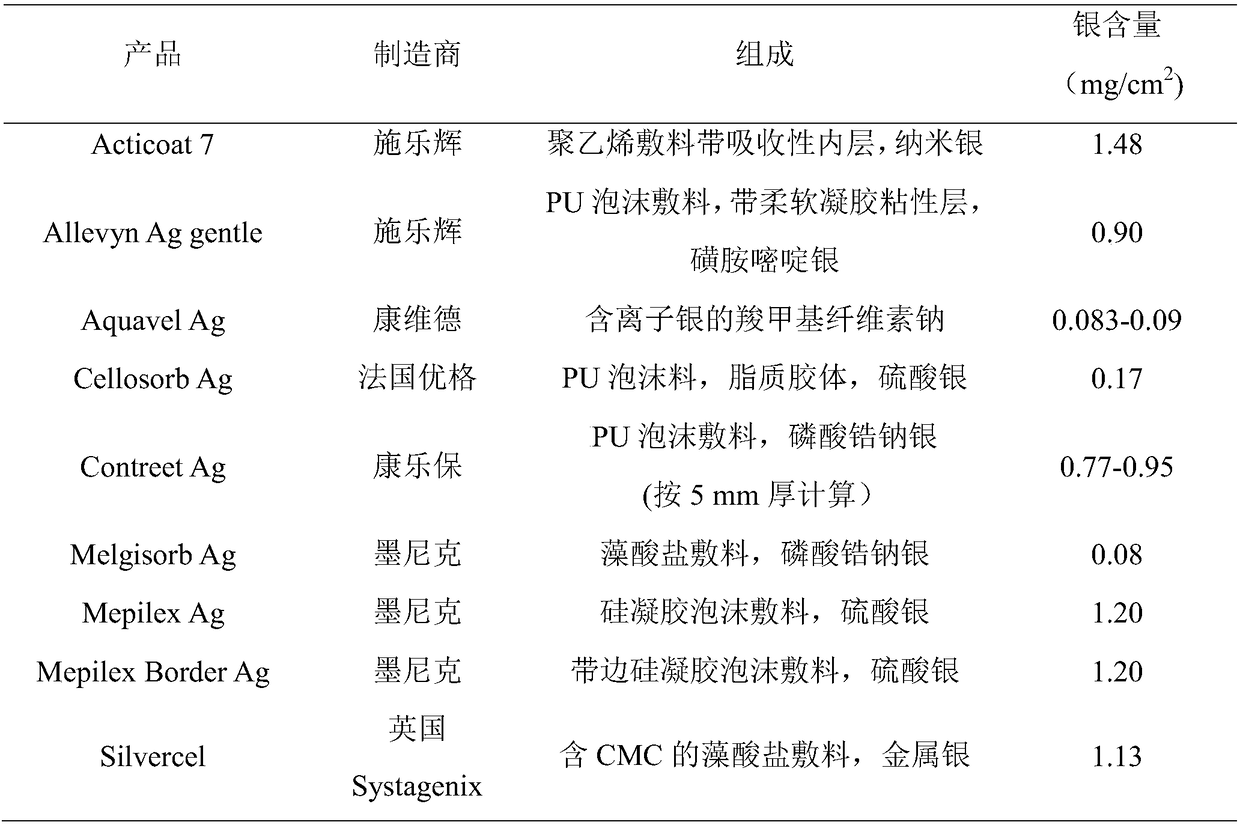

A hydrophilic polyurethane, silver ion technology, applied in medical science, bandages, etc., can solve the problems of poor slow release effect of antibacterial ingredients, complicated production of polyurethane silver ion dressings, low processing efficiency, etc. Effectiveness, facilitates sufficient exposure to bacteria, and prevents wound infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

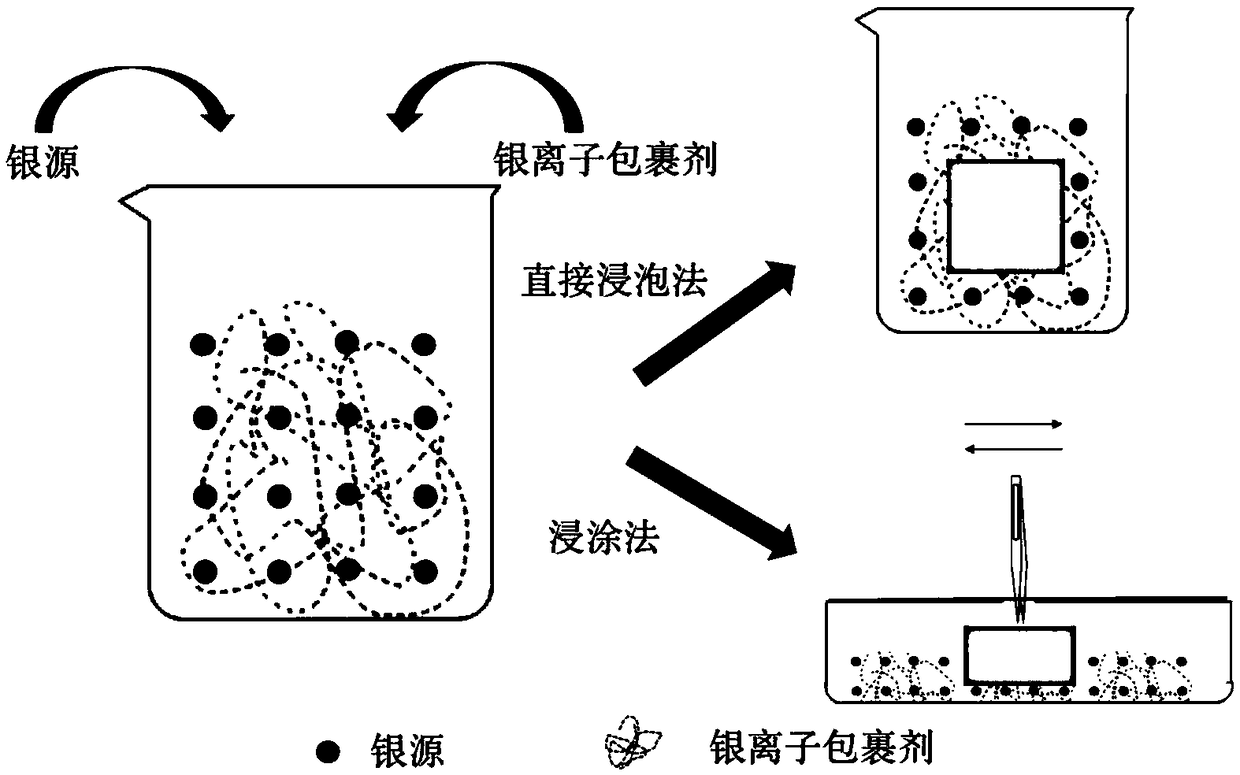

[0028] like figure 1 Shown, a kind of new method that the present invention proposes to prepare hydrophilic polyurethane silver ion dressing comprises the following steps,

[0029] S1, preparation of silver ion aqueous solution: mix and stir in 0.0145g silver sulfate, 100g water;

[0030] S2, preparation of silver ion encapsulating agent aqueous solution: 0.1002g tannic acid is dissolved in 66.66g deionized water, then mix and stir with 20.04g concentration be the polyvinyl alcohol solution of 3.0%;

[0031] S3. Ultrasonic impregnation and drying: impregnate the polyurethane foam in the aqueous solution of silver ion coating agent for 30 minutes, take it out and freeze-dry it at -50°C for 24 hours in the dark, and then perform a second ultrasonic impregnation of the polyurethane foam in the aqueous solution of silver ions. 150W, ultrasonic impregnation time is 30min, take out after impregnation and freeze-dry at -50℃ for 24h in the dark;

Embodiment 2

[0035] S1, preparation of silver ion aqueous solution: mix and stir in 0.0868g silver sulfate, 100g water;

[0036] S2, preparation of silver ion encapsulating agent aqueous solution: 0.1002g of tannic acid is dissolved in 66.66g of deionized water, and then mixed with 33.34g of polyvinyl alcohol solution with a concentration of 3.0% and stirred evenly;

[0037] S3. Ultrasonic impregnation Ultrasonic impregnation and drying: impregnate the polyurethane foam in the aqueous solution of silver ion coating agent for 30 minutes, take it out and freeze-dry it at -50°C for 24 hours in the dark, and then perform a second ultrasonic impregnation of the polyurethane foam in the aqueous solution of silver ions, wherein The ultrasonic power is 150W, and the ultrasonic impregnation time is 30min. After impregnation, take it out and freeze-dry it at -50°C for 24h in the dark;

[0038] S4, high-energy ray radiation sterilization: the dry polyurethane foam dressing prepared in step S3 with 6...

Embodiment 3

[0041] S1, preparation of silver ion aqueous solution: mix and stir in 0.145g silver sulfate, 100g water;

[0042] S2, preparation of silver ion encapsulating agent aqueous solution: 0.1002g of tannic acid is dissolved in 66.66g of deionized water, then mixes and stirs evenly with 40.08g concentration of polyvinyl alcohol solution of 3.0%;

[0043] S3. Ultrasonic impregnation: Immerse the polyurethane foam in the aqueous solution of silver ion coating agent for 30 minutes, take it out and freeze-dry it at -50°C for 24 hours in the dark, and then ultrasonically impregnate the polyurethane foam in the aqueous solution of silver ions. The ultrasonic power is 150W. The immersion time is 30min. After immersion, take it out and freeze-dry it at -50℃ for 24h in the dark;

[0044] S4, high-energy ray radiation sterilization: the dry polyurethane foam dressing prepared in step S3 with 60 Co is the γ-ray radiation source, and the radiation dose is 30kGy for radiation sterilization.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com