A Type I/Type III Collagen Composite Scaffold Loaded with Mildew Spatholobus

A composite scaffold and the technology of Millipede spathifolia, applied in the field of biomedicine, can solve the problems of inability to fully restore the healthy shape and physiological functions of damaged cartilage tissue, secondary lesions at the donor site, and limited donor sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

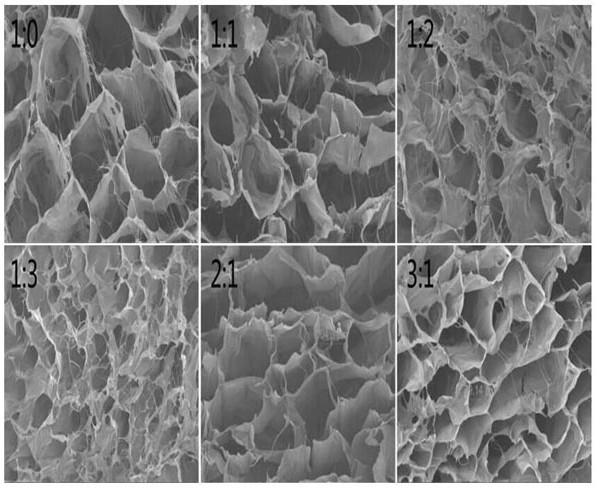

Embodiment 1

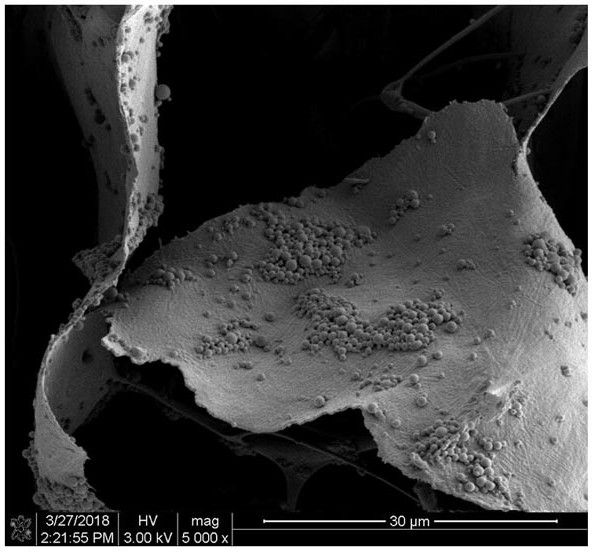

[0032] (1) ① Accurately weigh 0.06 g PLGA (molecular weight: 50,000, ratio: 75:25), dissolve in 1.2 mL of dichloromethane, and store in a refrigerator at 4°C for later use; ② Accurately weigh 0.5 mg of Spatholobus Spatholobus Place in 10 mL of ultrapure water, and dissolve it completely at 37°C; ③accurately weigh 0.09 g of PVA, place it in 9 mL of ultrapure water, and dissolve it completely in a water bath at 60°C; Take 600 uL of the Caulis Spatholobus solution described in step ② and slowly inject it into the PLGA solution described in step ①; will step The mixed liquid was emulsified in an ice-water bath for 2 minutes with a cell disruptor with a probe amplitude of 35% and a 3 mm conical probe (power of 200 W) to form colostrum; will step The colostrum formed in the step is immediately poured into the PVA solution, then use the steps Emulsify in an ice-water bath for 2 min in the cell disruptor to form a double emulsion; will step The double emulsion is fully ...

Embodiment 2

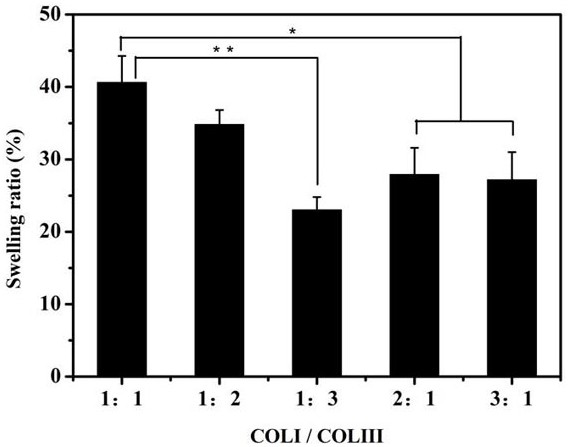

[0038] Change 0.8% beef tendon in step 4) Type collagen solution, 0.8% recombinant human source The mass ratio of type collagen solution was 1:2, and other steps were the same as in Example 1 to prepare composite material B. Its porosity and swelling rate can be as high as 83.9% and 40.1%, respectively.

Embodiment 3

[0040] Change 0.8% beef tendon in step 4) Type collagen solution, 0.8% recombinant human source The mass ratio of type collagen solution was 1:3, and other steps were the same as in Example 1 to prepare composite material C. Its porosity and swelling rate can be as high as 84.1 % and 40.2 %, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com