Energy-saving and emission-reducing extruder tail gas treatment device

A tail gas treatment, energy saving and emission reduction technology, applied in gas treatment, transportation and packaging, dispersed particle filtration, etc., can solve the problems of exhaust gas decomposition and deodorization, dust cleaning, gas content detection, etc., to achieve deodorization effect Good, wide application range, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

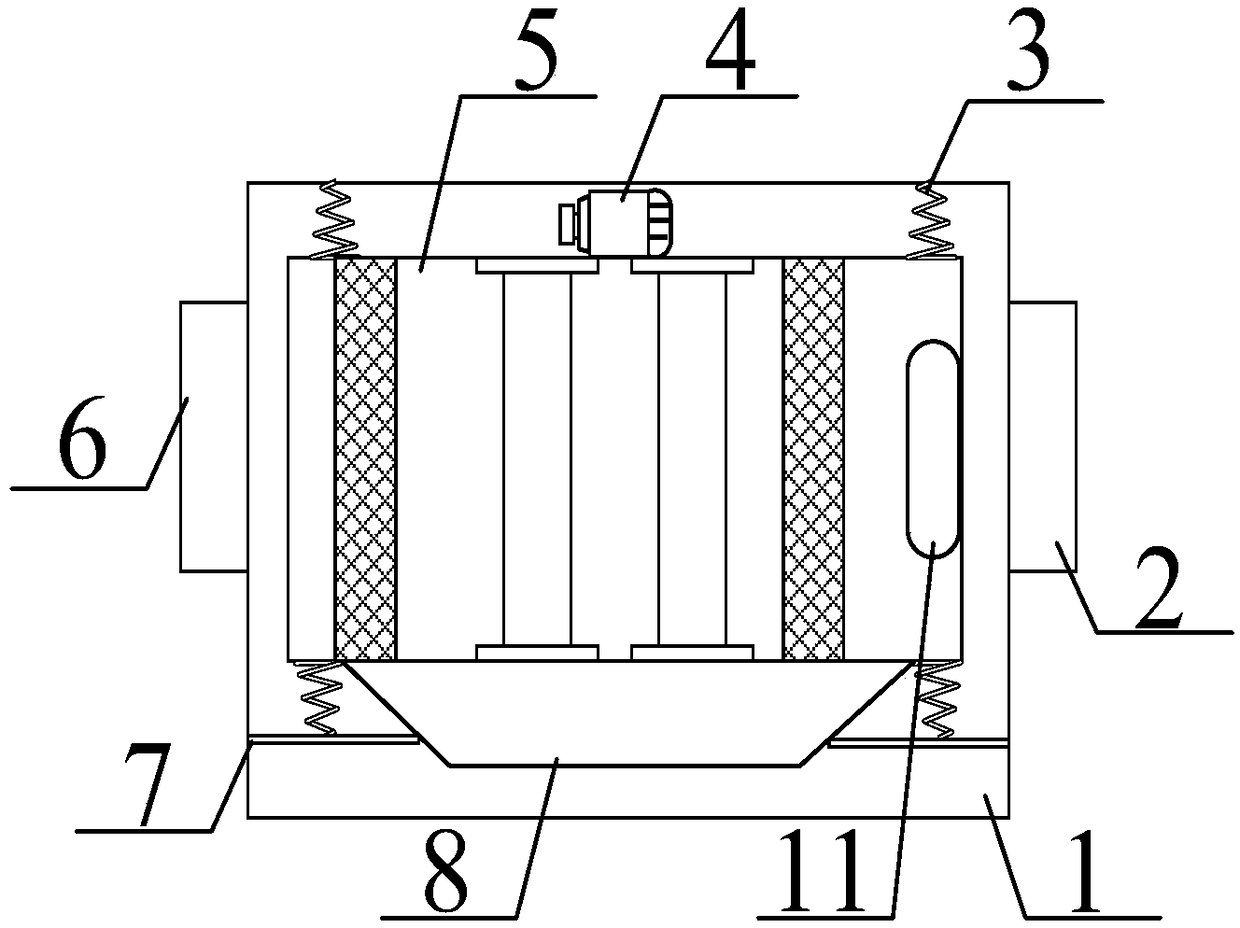

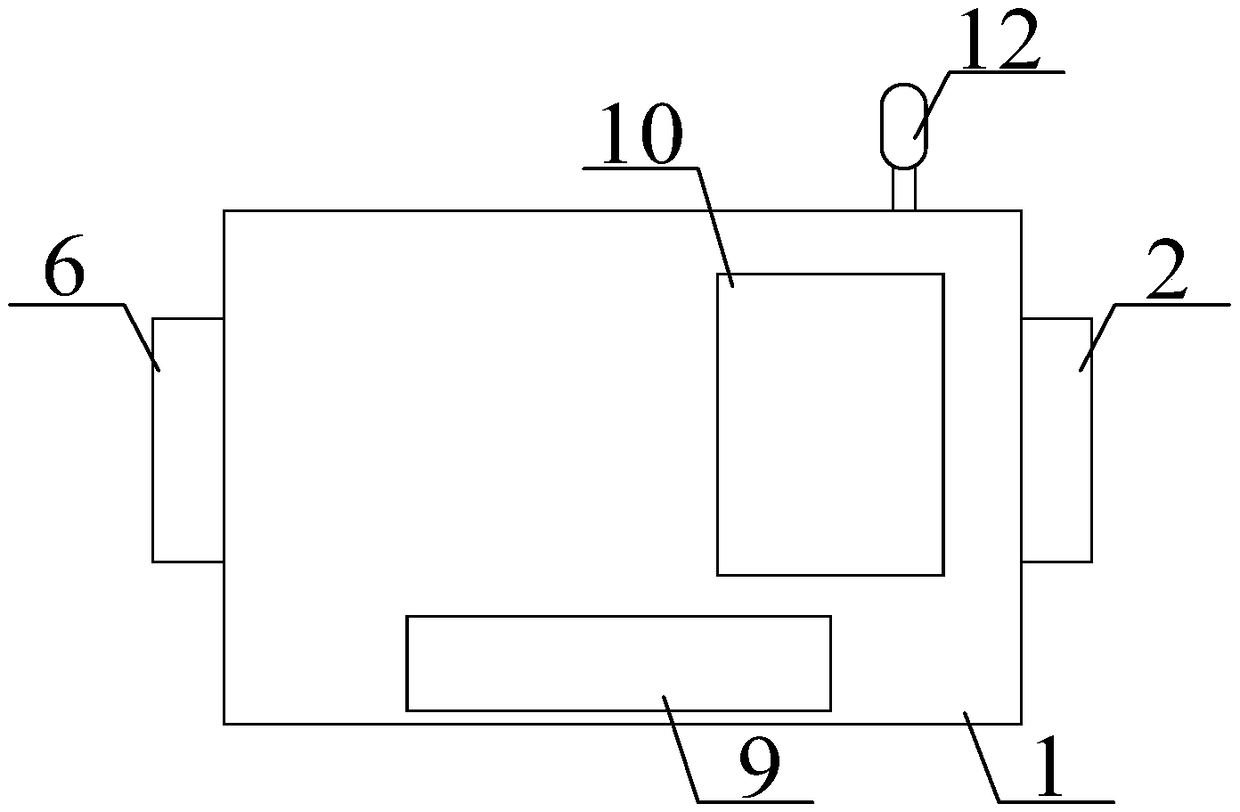

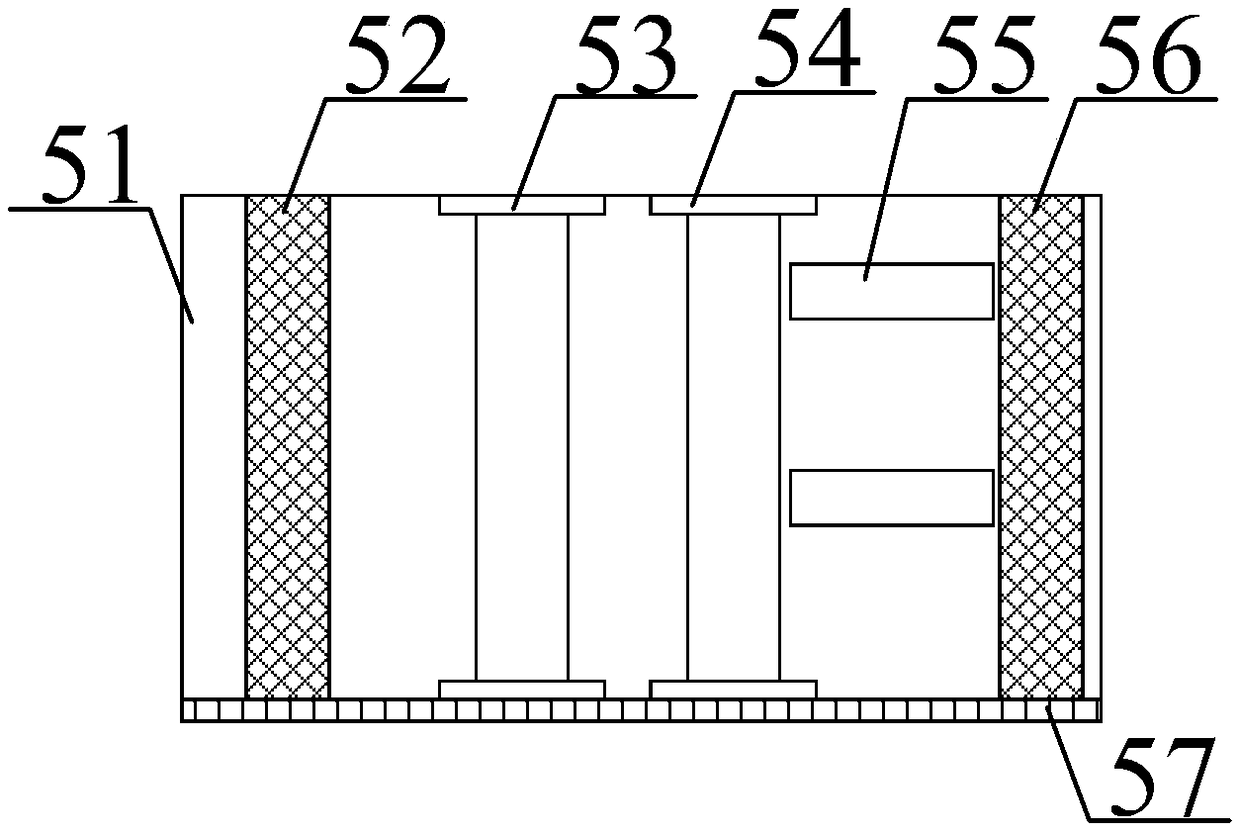

[0022] as attached figure 1 to attach image 3 shown

[0023] The invention provides an energy-saving and emission-reducing extruder tail gas treatment device, which includes a box body 1, an exhaust port 2, a spring 3, a vibration motor 4, a tail gas treatment mechanism 5, a tail gas inlet 6, a support plate 7, and a slag guide port 8, slag discharge box 9, control cabinet 10, oxygen sensor 11 and sound and light alarm 12, the exhaust port 2 is set in a hollow cylindrical shape, welded on the right end of the box body 1, and runs through the box body 1; the spring 3, four are used, arranged between the exhaust gas treatment mechanism 5, the box body 1 and the support plate 7, and fixed by welding; the vibration motor 4 is installed in the middle position of the top of the exhaust gas treatment mechanism 5 through bolts; the exhaust gas treatment mechanism 5 It is arranged inside the box body 1 and connected to the control cabinet 10 through wires; the exhaust gas inlet 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com