Method for separating rare multi-metal concentrate and quartz feldspar concentrate

A polymetallic and concentrate technology, applied in solid separation, mechanical material recovery, recycling technology, etc., can solve the problems of large amount of tailings, low recovery rate, environmental and safety hazards, etc., achieve good environmental benefits, improve rich Set ratio, the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

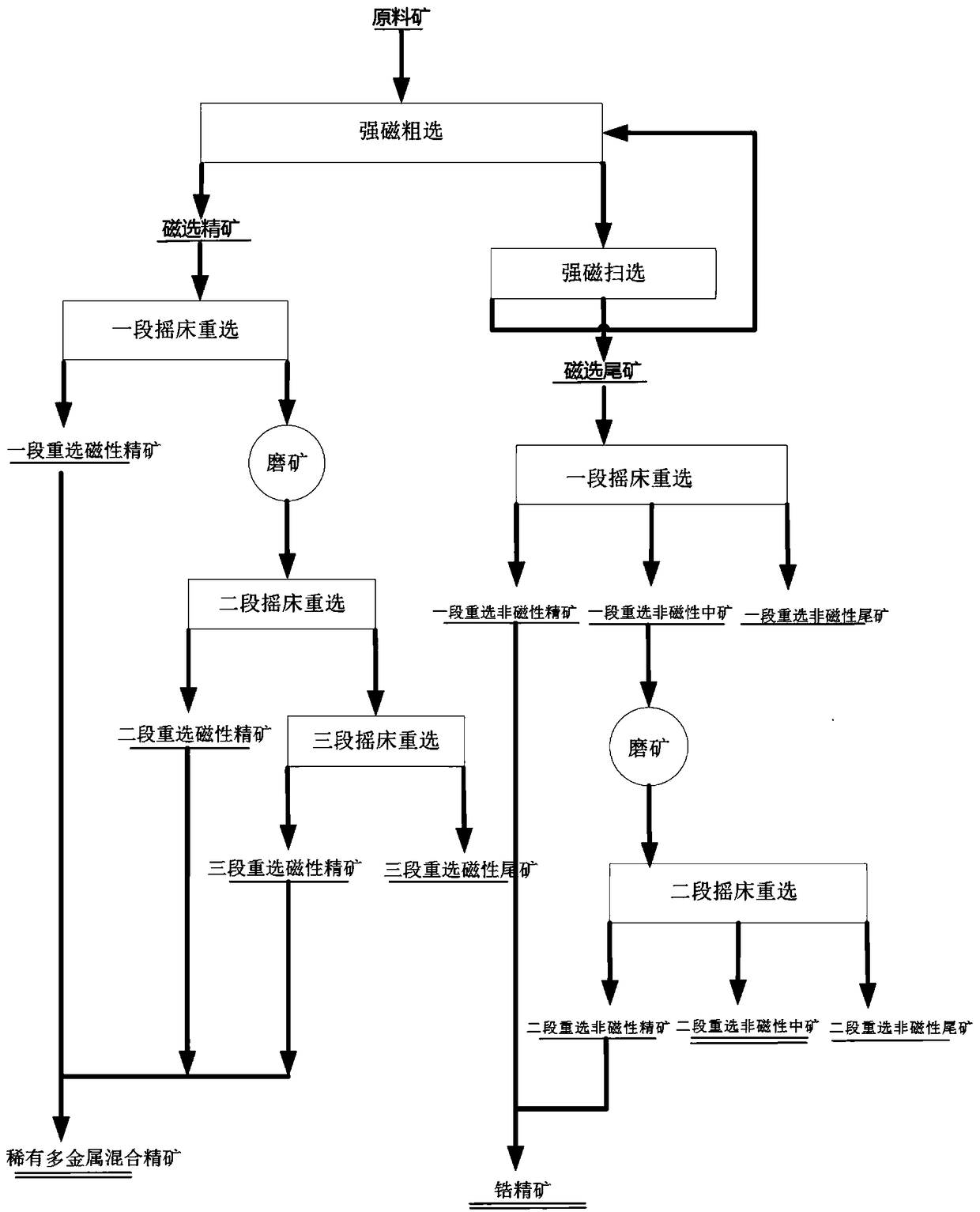

Image

Examples

Embodiment 1

[0034] With 5.00% total amount of rare metal zirconium, uranium, niobium, beryllium, rare earth and titanium minerals, Inner Mongolia 801 ore with 90% quartz feldspar content is used as raw material ore, and the following process steps are carried out by using the process method of the present invention:

[0035] (1) Strong magnetic separation: Take 1 kg of raw material ore with a particle size of -0.5mm accounting for 50%, and carry out a magnetic separation closed-circuit process of strong magnetic roughing and strong magnetic sweeping. The tailings are selected for strong magnetic scavenging, and the scavenging concentrate returns to the strong magnetic roughing process. The scavenging tailings are magnetic separation tailings. The magnetic field strength of the strong magnetic rough separation is 2.5T, and the magnetic field strength of the strong magnetic sweep is 1.6T;

[0036] (2) Magnetic separation concentrate re-election: Magnetic separation concentrate carries out o...

Embodiment 2

[0044] With the rare metal zirconium, uranium, niobium, beryllium, rare earth, titanium mineral total amount being 8.65%, Inner Mongolia 801 ore with a quartz feldspar content of 75.00% as a raw material ore, using the process method of the present invention, the following process steps are carried out:

[0045] (1) Strong magnetic separation: Take 1 kg of raw material ore with a particle size of -0.5mm accounting for 60.45%, and carry out a magnetic separation closed-circuit process of strong magnetic roughing and strong magnetic sweeping. The tailings are selected for strong magnetic scavenging, and the scavenging concentrate is returned to the strong magnetic roughing process. The scavenging tailings are magnetic separation tailings. 3.5T;

[0046] (2) Magnetic separation concentrate re-election: Magnetic separation concentrate is subjected to one stage of shaking table gravity separation, one stage of shaking table gravity separation obtains one stage of gravity separation...

Embodiment 3

[0054] With the rare metal zirconium, uranium, niobium, beryllium, rare earth, titanium mineral total amount of 10.25%, Inner Mongolia 801 ore with a quartz feldspar content of 82.67% is used as a raw material ore, and the process of the present invention is used to carry out the following process steps:

[0055] (1) Strong magnetic separation: Take 1 kg of raw material ore with a particle size of -0.5mm accounting for 55.63%, and carry out a magnetic separation closed-circuit process of strong magnetic roughing and strong magnetic sweeping. The tailings are subjected to strong magnetic scavenging, and the scavenging concentrate is returned to the strong magnetic roughing process. The scavenging tailings are magnetic separation tailings. 3.0T;

[0056] (2) Magnetic separation concentrate re-election: Magnetic separation concentrate is subjected to one stage of shaking table gravity separation, one stage of shaking table gravity separation obtains one stage of gravity separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com