High-content syenite low-cost zirconium-free opaque glaze and preparation method and application thereof

A technology of syenite and opaque glaze is applied in the field of high-content syenite and low-cost zirconium-free opaque glaze and its preparation, and can solve the problems of high price of zircon, poor flatness of glaze, harmful to human health, etc. problems, to achieve the effects of green and environmental protection of raw materials, reducing firing temperature and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

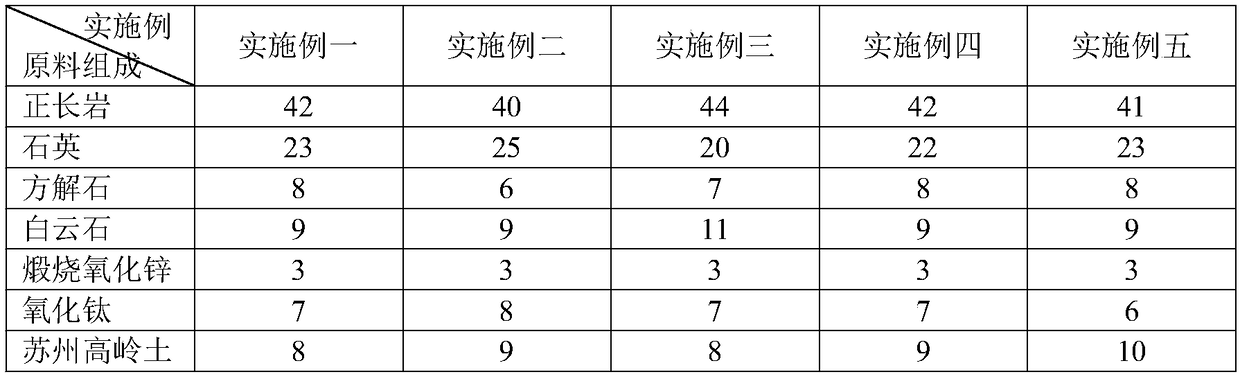

[0020] An embodiment of the present invention is a low-cost zirconium-free opaque glaze with high content of syenite. The main raw materials are: 40-45 parts of syenite, 20-25 parts of quartz, 6-10 parts of calcite, dolomite 9-11 parts of limestone, 2-5 parts of calcined zinc oxide, 6-9 parts of titanium oxide, and 7-10 parts of Suzhou kaolin. The raw material composition of each embodiment is as shown in table 1.

[0021] The mineral composition of the adopted syenite is mainly 75 wt% of alkaline feldspar, 10 wt% of plagioclase, 5 wt% of amphibole, 5 wt% of biotite and 5 wt% of quartz. Its chemical composition is SiO 2 62.84%, TiO 2 0.50%, Al 2 o 3 17.12%, Fe 2 o 3 3.01%, MgO 1.35%, CaO 1.72%, Na 2 O 6.11%, K 2 O 5.12%, P 2 o 5 0.18%, I.L. 2.05%.

[0022] Table 1 Raw material composition (parts by weight) of high-dosage syenite low-cost zirconium-free opaque glaze in various embodiments of the present invention

[0023]

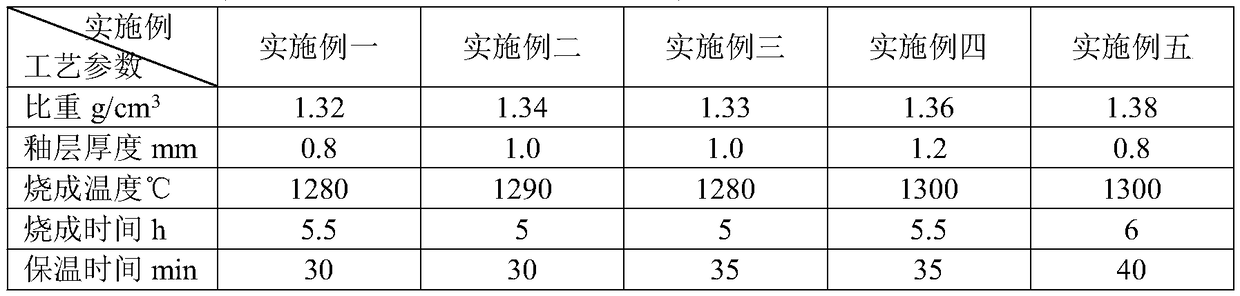

[0024] The preparation method of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com