ALC wallboard containing construction waste and preparation method thereof

A construction waste and wallboard technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of high cost and limit the application and popularization of ALC board, and achieve the effect of low cost, improved organizational structure and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

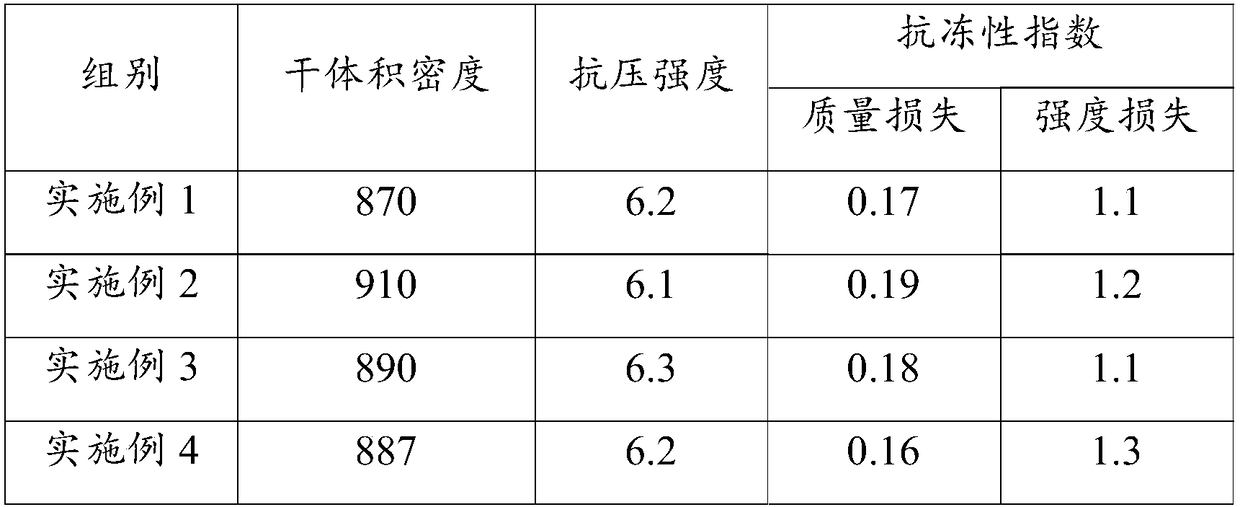

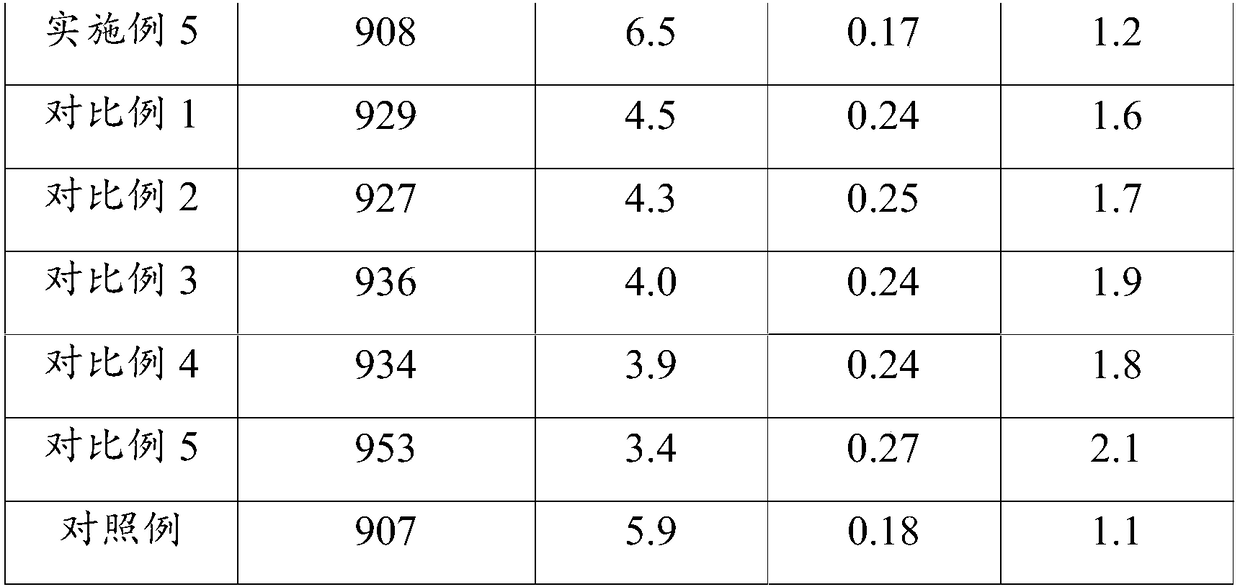

Examples

preparation example Construction

[0050] According to one aspect of the present invention, a kind of preparation method of above-mentioned ALC wallboard containing construction waste, described preparation method comprises the following steps:

[0051] First, mix cement, construction waste aggregate, gypsum, phenolic resin, anti-cracking waterproofing agent and water evenly under a magnetic field strength of 0.004-0.005T, then add soluble oil and aluminum powder suspension and stir to make slurry, and then the prepared The slurry is poured on the multi-layer steel mesh coated with asphalt, and then the ALC wallboard containing construction waste is made through gasification.

[0052] The preparation method of the ALC wallboard containing construction waste provided by the invention, the method first mixes cement, construction waste aggregate, gypsum, phenolic resin, anti-cracking waterproofing agent and water under a magnetic field condition, and then adds soluble oil and aluminum The powder suspension is stir...

Embodiment 1

[0063] An ALC wallboard containing construction waste, in terms of parts by mass, said ALC wallboard is mainly made of the following raw materials: 10 parts of 325 Portland cement, 40 parts of construction waste aggregate, 12 parts of gypsum, phenolic resin 5 parts, 2 parts of SY-K expansion fiber anti-cracking waterproof agent, 5 parts of soluble oil, 130 parts of aluminum powder suspension and 50 parts of water;

[0064] The construction waste aggregate obtained by crushing the construction waste has a particle size of 1mm;

[0065] The soluble oil is mainly prepared by mixing and stirring oleic acid, triethanolamine and water at a molar mass ratio of 1:2:30 at 40°C for 30 minutes;

[0066] The aluminum powder suspension is mainly prepared by mixing aluminum powder, Pingping and water at a molar mass ratio of 1:2:20 at 50°C for 1 min;

[0067] The preparation method of the above-mentioned ALC wallboard containing construction waste comprises the following steps:

[0068] F...

Embodiment 2

[0070] An ALC wallboard containing construction waste, in terms of parts by mass, said ALC wallboard is mainly made of the following raw materials: 30 parts of 425 portland cement, 60 parts of construction waste aggregate, 28 parts of gypsum, phenolic resin 15 parts, 8 parts of SY-K expansion fiber anti-cracking waterproof agent, 15 parts of soluble oil, 180 parts of aluminum powder suspension and 80 parts of water;

[0071] The construction waste aggregate obtained by crushing the construction waste has a particle size of 3mm;

[0072] The soluble oil is mainly prepared by mixing and stirring oleic acid, triethanolamine and water at a molar mass ratio of 2:5:40 at 50°C for 50 minutes;

[0073] The aluminum powder suspension is mainly prepared by mixing and stirring aluminum paste, pull-off powder and water at a molar mass ratio of 2:4:30 at 60°C for 3 minutes;

[0074] The preparation method of the above-mentioned ALC wallboard containing construction waste comprises the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com