UV-type graphene quantum dot/nano-silver wire composite solvent-based conductive ink and flexible transparent conductive film based thereon

A technology of graphene quantum dots and transparent conductive films, which can be used in inks, household appliances, applications, etc., can solve the problems of inapplicability of flexible transparent conductive films, poor optical properties of conductive films, and inapplicability of large-size displays. Leveling, improving light and heat stability, and improving the effect of light and heat stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Preparation of composite solvent-based conductive ink:

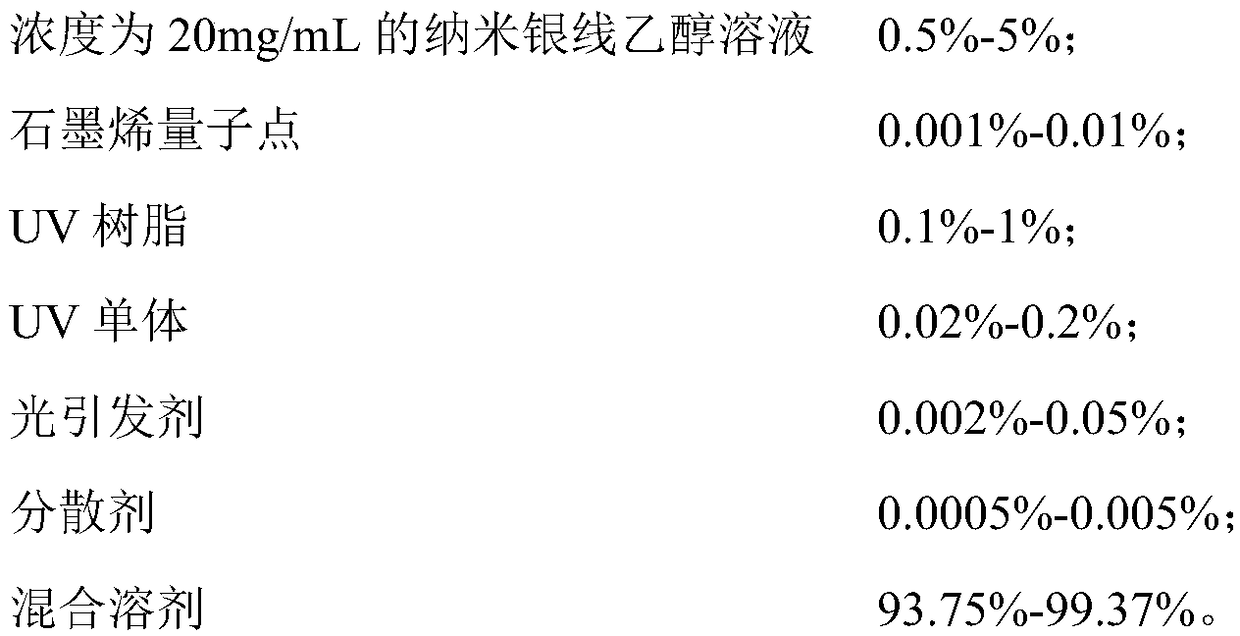

[0069] The raw materials of the UV-type graphene quantum dots / nano-silver wire composite solvent-based conductive ink in this embodiment are composed of the following mass percentages:

[0070]

[0071] The specific preparation method is as follows:

[0072] a. Add graphene oxide into water, and disperse evenly by ultrasonic to obtain an aqueous solution of graphene oxide with a concentration of 10mg / mL, and pour it into a closed flask, and use an oven to treat it at 210°C for 15h, then cool and centrifuge, and the obtained precipitate is dried Afterwards, graphene quantum dots with thickness≤1nm and sheet diameter≤20nm are obtained.

[0073] Dilute the silver nanowires with ethanol to a 20mg / mL dispersion;

[0074] b. Accurately weigh each raw material according to the ratio;

[0075] c. In a clean room, under yellow light, add the mixed solvent and dispersant to the dispersing tank at one time, mechani...

Embodiment 2

[0083] (1) Preparation of composite solvent-based conductive ink:

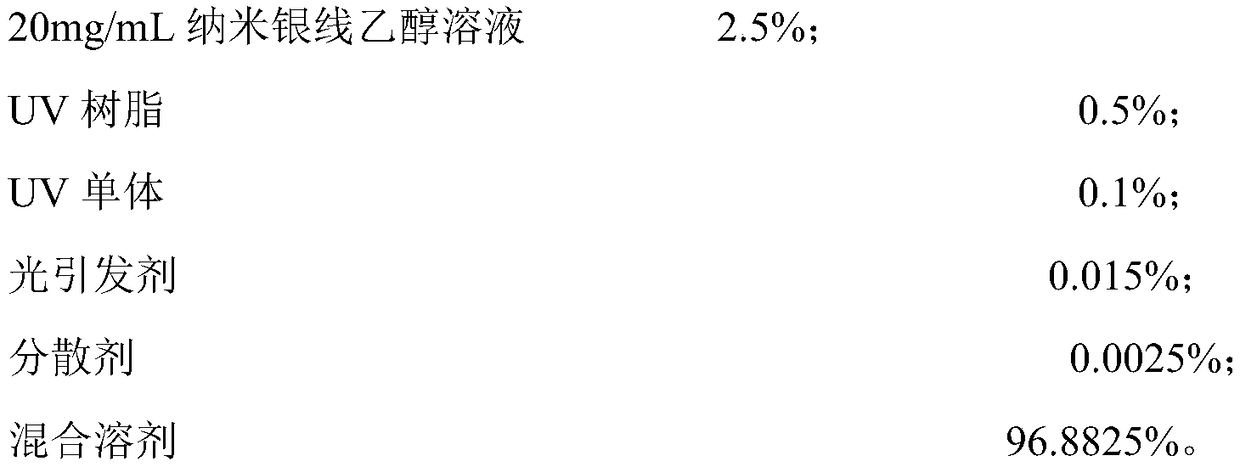

[0084] The raw materials of the UV-type graphene quantum dots / nano-silver wire composite solvent-based conductive ink in this embodiment are composed of the following mass percentages:

[0085]

[0086] The specific preparation method is as follows:

[0087] a. Add graphene oxide into water, and disperse evenly by ultrasonic to obtain an aqueous solution of graphene oxide with a concentration of 10mg / mL, and pour it into a closed flask, and use an oven to treat it at 210°C for 15h, then cool and centrifuge, and the obtained precipitate is dried Afterwards, graphene quantum dots with thickness≤1nm and sheet diameter≤20nm are obtained.

[0088] Dilute the silver nanowires with ethanol to a 20mg / mL dispersion;

[0089] b. Accurately weigh each raw material according to the ratio;

[0090] c. In a clean room, under yellow light, add the mixed solvent and dispersant to the dispersing tank at one time, mechani...

Embodiment 3

[0098] (1) Preparation of composite solvent-based conductive ink:

[0099] The raw materials of the UV-type graphene quantum dots / nano-silver wire composite solvent-based conductive ink in this embodiment are composed of the following mass percentages:

[0100]

[0101] The specific preparation method is as follows:

[0102] a. Add graphene oxide into water, and disperse evenly by ultrasonic to obtain an aqueous solution of graphene oxide with a concentration of 10mg / mL, and pour it into a closed flask, and use an oven to treat it at 210°C for 15h, then cool and centrifuge, and the obtained precipitate is dried Afterwards, graphene quantum dots with thickness≤1nm and sheet diameter≤20nm are obtained.

[0103] Dilute the silver nanowires with ethanol to a 20mg / mL dispersion;

[0104]b. Accurately weigh each raw material according to the ratio;

[0105] c. In a clean room, under yellow light, add the mixed solvent and dispersant to the dispersing tank at one time, mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com