Water-based engineering machinery decoration finishing coat and preparation method thereof

A kind of construction machinery and water-based technology, applied in the field of coatings, can solve the problems of water-based paint products, such as the gap in construction performance, high VOCs content in paint, and unsuitability for open-air construction, and achieve the effects of good environmental performance, good yellowing resistance, and fast hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

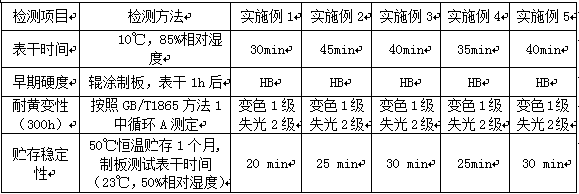

Examples

Embodiment 1

[0040] Water-based construction machinery decorative finish paint, including the following raw materials in weight percentage: 40% water-based alkyd resin, 0.5% water-based drier, 1% titanium dioxide, 20% molybdenum chrome red, 15% barium sulfate, 2 % propylene glycol butyl ether, 0.1% dimethylethanolamine, 0.2% defoamer (Tego-902w), 0.4% leveling agent (PW-336), 0.3% substrate wetting agent, 20% Deionized water, 0.5% thickener.

Embodiment 2

[0042] Water-based construction machinery decorative finish paint, including the following raw materials in weight percentage: 50% water-based alkyd resin, 0.3% water-based drier, 1% titanium dioxide, 10% molybdenum chrome red, 10% barium sulfate, 1 % environmentally friendly solvent, 0.2% dimethylethanolamine, 0.5% defoamer (Tego-902w), 0.6% leveling agent (PW-336), 0.4% substrate wetting agent, 25% defoamer Ionized water, 1% thickener.

Embodiment 3

[0044] Water-based construction machinery decorative finish paint, including the following raw materials in weight percentage: 59% water-based alkyd resin, 0.5% water-based drier, 2% titanium dioxide, 10% molybdenum chrome red, 6% barium sulfate, 1 % propylene glycol butyl ether, 0.1% dimethylethanolamine, 0.2% defoamer (Tego-902w), 0.4% leveling agent (PW-336), 0.3% substrate wetting agent (Tego-245 ), 20% deionized water, 0.5% thickener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com