Glue and synthesis method thereof

A synthesis method and glue technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of large odor, high cost, low viscosity, etc., and achieve the effect of simple reaction feeding and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Stir and mix 4 parts of isopropanol, 20 parts of methyl ethyl ketone, and 12 parts of vinyl acetate. After heating up, add 14 parts of trimethoxysilane, 10 parts of carbon tetrachloride, 12 parts of styrene, and benzene peroxide 7 parts of formyl, 16 parts of difluorotetrachloroethane, after reacting for 2 hours, add 6 parts of butyl acetate, 14 parts of sodium benzoate, 8 parts of methyl cellulose, 10 parts of stearic acid, 6 parts of perchloroethylene resin 4 parts of trimethoxysilane were placed in a thermostatically controlled water bath at 38°C, and the pH value was adjusted to 7.8 by a pH meter. After the reaction, sample 1 was obtained.

Embodiment 2

[0013] Stir and mix 4 parts of isopropanol, 22 parts of methyl ethyl ketone, and 14 parts of vinyl acetate. After heating up, add 16 parts of trimethoxysilane, 10 parts of carbon tetrachloride, 14 parts of styrene, and benzene peroxide 6 parts of formyl, 14 parts of difluorotetrachloroethane, after reacting for 2 hours, add 6 parts of butyl acetate, 16 parts of sodium benzoate, 10 parts of methyl cellulose, 10 parts of stearic acid, and 8 parts of perchloroethylene resin 5 parts, 5 parts of trimethoxysilane were placed in a thermostatically controlled water bath at 42°C, and the pH value was adjusted to 8.0 by a pH meter. After the reaction, sample 2 was obtained.

Embodiment 3

[0015] Stir and mix 6 parts of isopropanol, 25 parts of methyl ethyl ketone, and 16 parts of vinyl acetate. After heating up, add 18 parts of trimethoxysilane, 14 parts of carbon tetrachloride, 16 parts of styrene, and benzene peroxide 8 parts of formyl, 12 parts of difluorotetrachloroethane, after reacting for 2 hours, add 8 parts of butyl acetate, 18 parts of sodium benzoate, 12 parts of methyl cellulose, 14 parts of stearic acid, and 12 parts of perchloroethylene resin 6 parts, 6 parts of trimethoxysilane were placed in a thermostatically controlled water bath at 45°C, and the pH value was adjusted to 8.5 by a pH meter. After the reaction, sample 3 was obtained.

[0016]

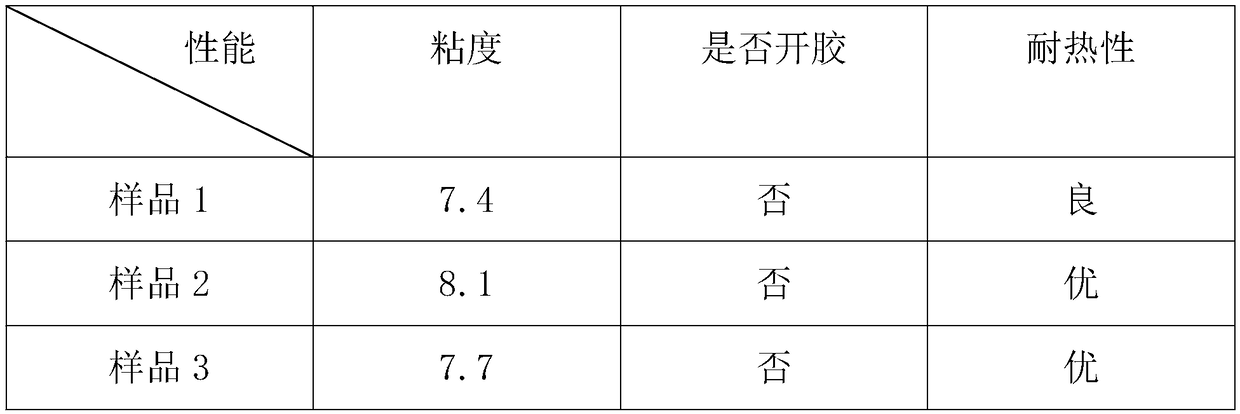

[0017] After checking the usability of the glue of the three samples, it can be obtained that the viscosity of the sample 2 is the largest, and it is not easy to open the glue after use, and has good heat resistance, so Example 2 is the optimal synthesis method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com