A kind of low-hydroxyl hydrogen-containing vinyl phenyl silicone resin and preparation method thereof

A technology of hydrogen vinyl phenyl and silicone, applied in the field of low hydroxyl hydrogen-containing vinyl phenyl silicone resin and its preparation, can solve the problems of poor electrical insulation performance, poor viscosity stability, high hydroxyl content, etc., and achieve stable viscosity Good resistance, good electrical insulation, and the effect of reducing the content of oligomers and silanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] PO(CH 2 OMe 2 SiC 3 h 6 NCO) 3 preparation

[0051] (a) 140g trihydroxymethyl phosphine oxide is put into reaction flask with three-way valve, stirring and constant pressure dropping funnel, evacuated nitrogen three times, 500ml toluene is injected in the reaction flask, 735g dimethylaminopropyl Dissolve methoxysilane in 200ml of toluene, put it into a constant pressure dropping funnel, and drop it into the reaction flask within 30 minutes. After the dropwise addition, the reaction was heated to reflux for 12h. Reaction finishes, evaporates solvent, excess dimethylaminopropyl methoxy silane and low boiler, obtains 485g PO (CH 2 OMe 2 SiC 3 h 6 NH 2 ) 3 .

[0052] (b) 485g PO(CH 2 OMe 2 SiC 3 h 6 NH 2 ) 3 Put it into a reaction flask equipped with a three-way valve, stirring and a constant pressure dropping funnel, evacuate and pass nitrogen three times, inject 1000ml of benzene and 600g of triethylamine into the reaction flask, and cool to -5°C. Add 2...

Embodiment 2

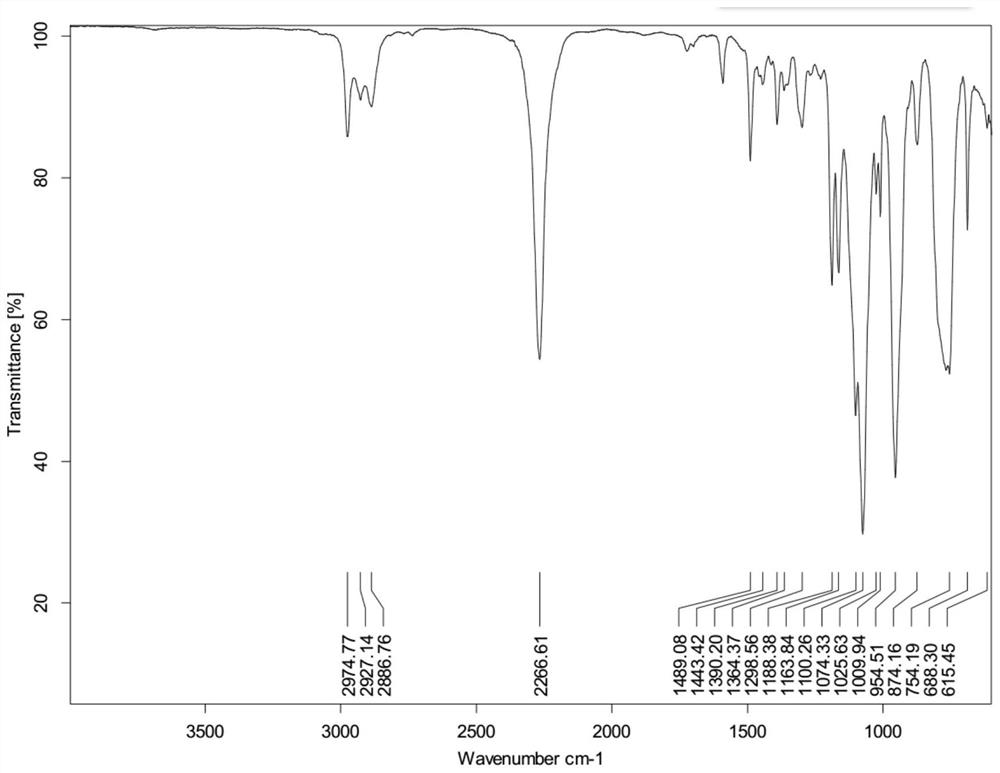

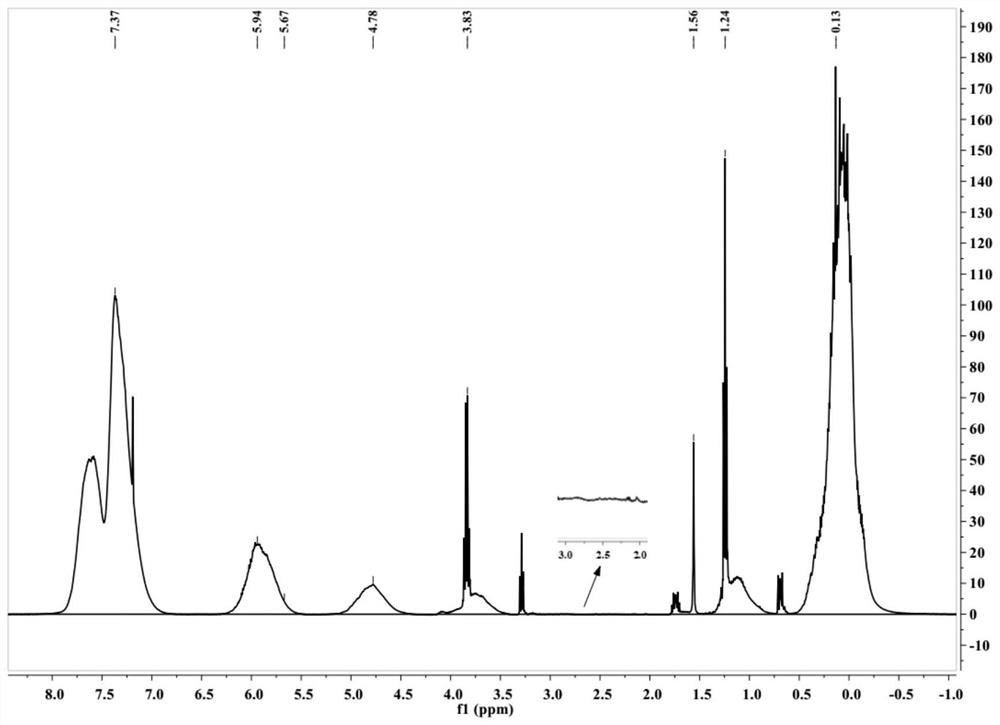

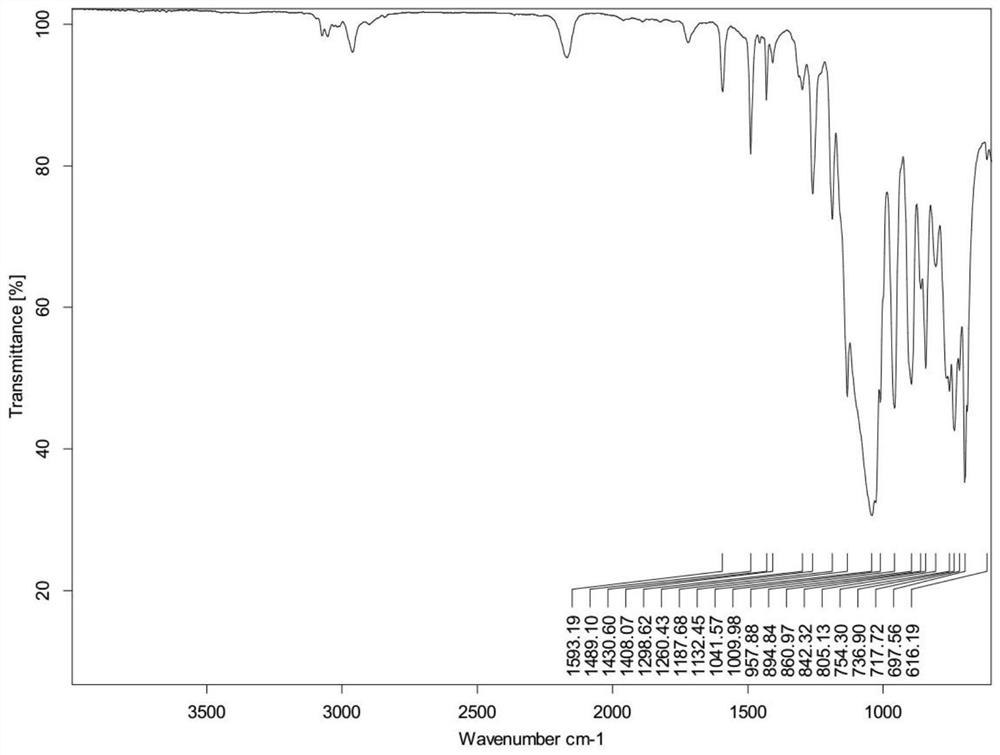

[0055] 378g water, 83g hydrogen type strongly acidic cation exchange resin, 41g p-toluenesulfonic acid, 450g toluene are charged in the reaction flask equipped with stirrer, heating, condenser distillation and dropping funnel. Under stirring, drop 2mol (480g) PhSi(OEt) through the dropping funnel 3 、1mol(134g)MeHSi(OEt) 2 , 1mol (160g) MeViSi (OEt) 2 , 0.5mol (52g) Me 3 SiOMe mixture, the dropping time is 25min. Raise the temperature to 70°C and react for 3h. After the reaction is complete, cool to room temperature. The solid was filtered off, and the acid water was separated. The organic layer was washed 500 mL×3 times with water until neutral, and the toluene was distilled off. The temperature was raised to 150° C. and maintained at a vacuum pressure of 50 hPa for 4 hours to obtain 450 g of silane hydrolyzate.

[0056] Under nitrogen protection, add 45g PO(CH 2 OMe 2 SiC 3 h 6 NCO) 3 , temperature controlled to 30°C, and reacted for 8h. After the reaction was co...

Embodiment 3

[0064] 4032g of water, 390g of hydrogen-type strongly acidic cation exchange resin, 25g of p-toluenesulfonic acid, and 1900g of benzene were charged into a reaction flask equipped with a stirrer, heating, condenser distillation and dropping funnel, and were stirred by dropping Add 6mol (1188g) PhSi(OMe) dropwise into the funnel 3 、3mol(402g)MeHSi(OEt) 2 , 1mol (132g) MeViSi (OMe) 2 , 2.0mol (236g) Me 3 SiOEt mixture, the dropwise addition time is 30min. Raise the temperature to 50°C and react for 8h. After the reaction is complete, cool to room temperature, filter off the solid, and separate the acid water. The organic layer was washed 1000mL×3 times with water until neutral, and the solvent benzene was distilled off. The temperature was raised to 100° C., and the vacuum pressure was maintained at 80 hPa for 2 hours to obtain 1250 g of organosilicon hydrolyzate.

[0065] Under nitrogen protection, add 108g PO(CH 2 OMe 2 SiC 3 h 6 NCO) 3 , heated up to 80°C, and reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotational viscosity | aaaaa | aaaaa |

| rotational viscosity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com