Water-saving and energy-saving precipitation production method of silicon dioxide

A technology of silicon dioxide and production methods, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as low efficiency, slow reaction rate between silanol and metal ions, failure to eliminate silanol, etc., to achieve The process is simple, the effect of reducing production water and drying energy consumption, reducing washing water and washing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

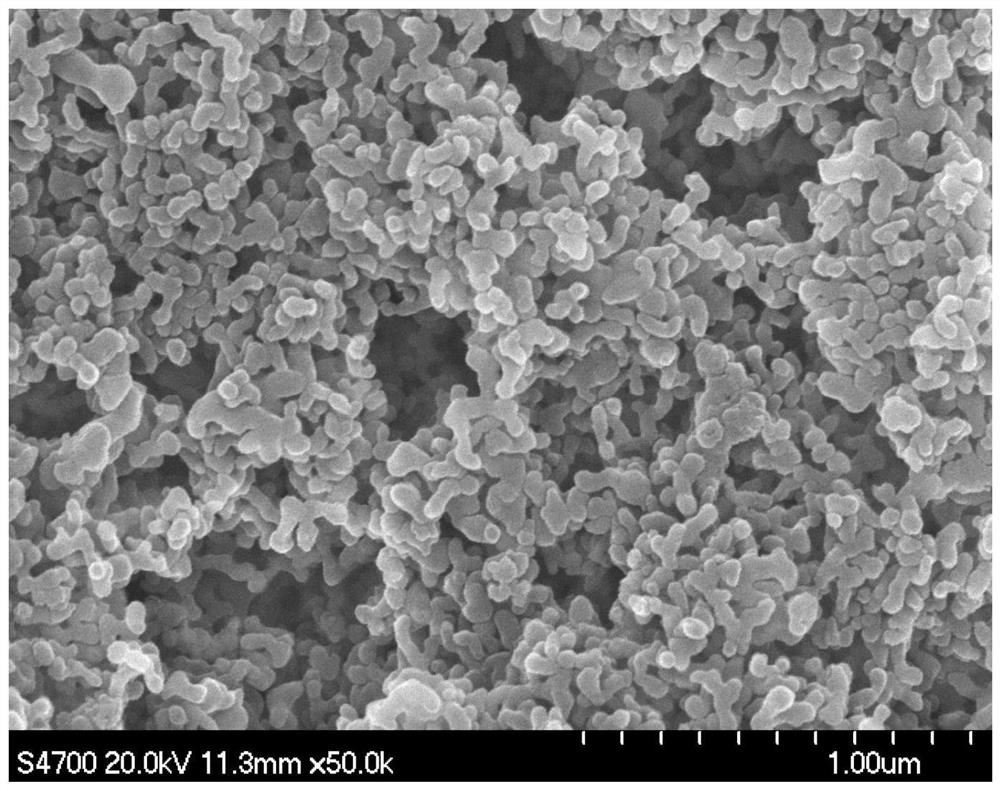

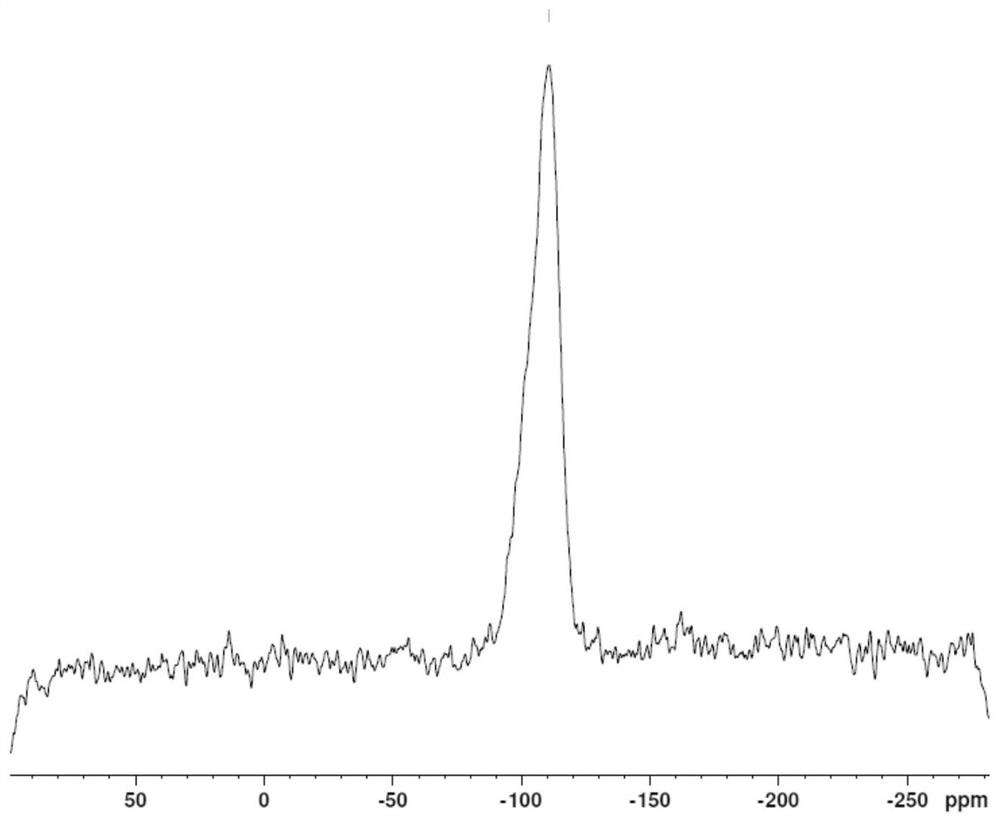

Image

Examples

Embodiment 1

[0042](1) Take 100 mL of water glass, add water to dilute to 500 mL, and stir well.

[0043] (2) The water glass dilution liquid prepared in step (1) is heated to 80° C., and the pH value is adjusted to 7.0 with 10 wt % sulfuric acid to form a dilute orthosilicate gel.

[0044] (3) The dilute orthosilicate gel was transferred to a 1000mL autoclave with a stirring speed of 200rpm, and heated to 170°C for 5 hours.

[0045] (4) Send 80 mL of a solution containing 2 g of magnesium sulfate from the auxiliary tank to the reaction kettle with high-pressure nitrogen, and continue the reaction at 170° C. for 1 hour.

[0046] (5) After the reaction is completed, the temperature is lowered to below 80° C., filtered with a Buchner funnel, washed until no sulfate is detected by barium chloride, and dried to obtain the product. The water used for beating and washing each filter cake was 800 mL, and the water was washed 3 times in total.

[0047] After testing, the water content of the fil...

Embodiment 2

[0049] (1) Take 100 mL of water glass, add water to dilute to 500 mL, and stir well.

[0050] (2) Heat the water glass dilution prepared in step (1) to 65° C., adjust the pH value to 7.0 with 10 wt % sulfuric acid, and form a dilute orthosilicate gel.

[0051] (3) The dilute orthosilicate gel was transferred to a 1000mL pressure reactor, the stirring speed was 200rpm, and the mixture was heated to 140°C for 10 hours.

[0052] (4) Use high-pressure nitrogen to send 80 mL of a solution in which 2.5 g of calcium nitrate is dissolved from the auxiliary tank to the reaction kettle, and continue the reaction at 140° C. for 1 hour.

[0053] (5) After the reaction is completed, the temperature is lowered to below 80° C., filtered with a Buchner funnel, washed until barium chloride does not contain sulfate radicals, and dried to obtain the product. The water used for beating and washing the filter cake was 800 mL each time, and the water was washed 4 times in total.

[0054] After te...

Embodiment 3

[0056] (1) Take 100 mL of water glass, add water to dilute to 500 mL, and stir well.

[0057] (2) The water glass dilution liquid prepared in step (1) is heated to 85° C., and the pH value is adjusted to 7.0 with 10 wt % sulfuric acid to form a dilute orthosilicate gel.

[0058] (3) The dilute orthosilicate gel was transferred to a 1000 mL pressure reactor with a stirring speed of 200 rpm, and heated to 200° C. for 4 hours.

[0059] (4) Reduce the temperature of the reactor to 160° C., and send 80 mL of a solution in which 3 g of magnesium sulfate is dissolved from the auxiliary tank to the reactor with nitrogen gas, and continue to react for 1 hour.

[0060] (5) After the reaction is completed, the temperature is lowered to below 80° C., filtered with a Buchner funnel, washed until the mother liquor is detected by barium chloride to contain no sulfate groups, and dried to obtain the product. Use 800 mL of water for each wash, and wash 3 times in total.

[0061] After testin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com