Method for preparing multilayer graphene

A technology of multi-layer graphene and acrylic acid, which is applied in the field of graphene material preparation, can solve the problems of high cost and complicated preparation process, and achieve the effects of convenient operation, abundant raw material sources, and mild and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

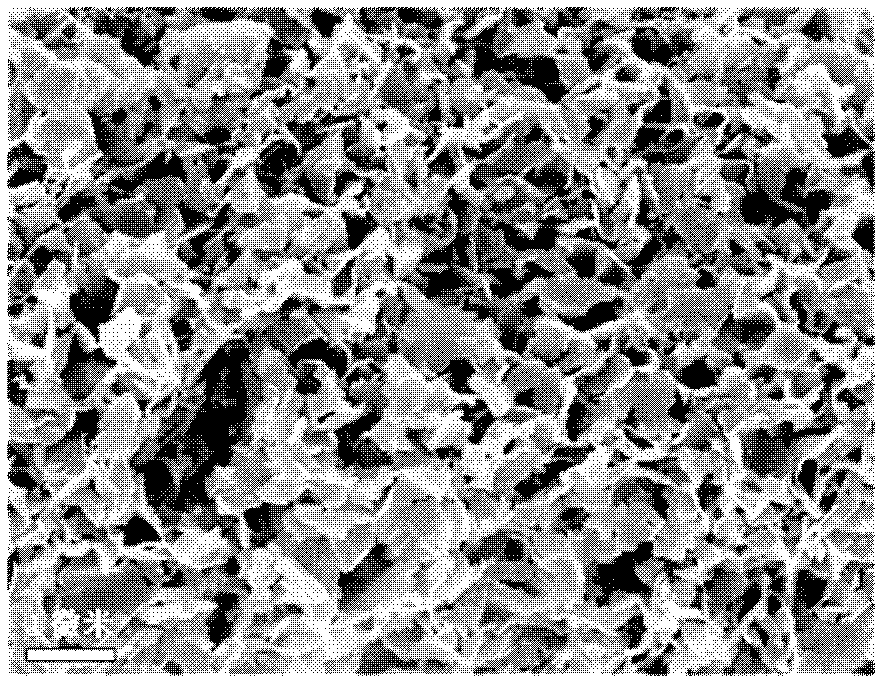

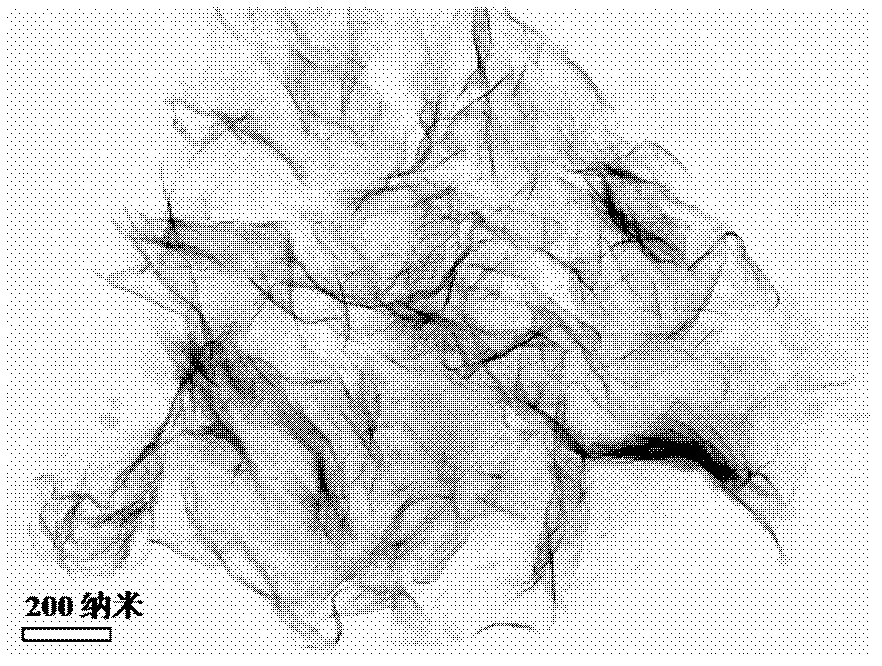

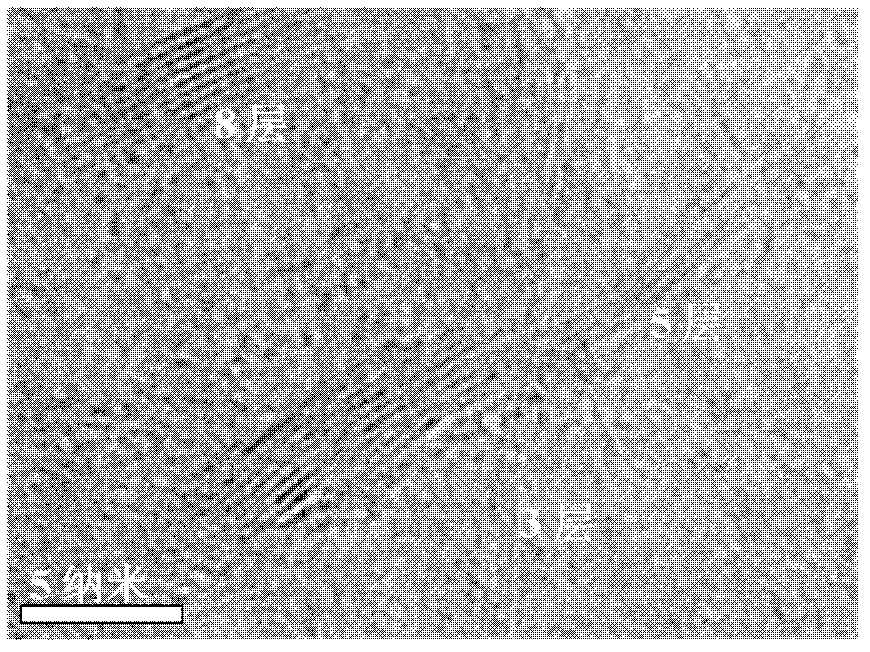

Image

Examples

Embodiment 1

[0032] After mixing sodium montmorillonite and cetyltrimethylammonium bromide in a mass ratio of 1:1, add it into distilled water at a liquid-solid mass ratio of 100ml / g, heat and stir at 80°C for 12h Centrifuge, wash with distilled water until neutral, and dry to obtain organically modified sodium-based montmorillonite.

[0033] In a three-necked flask equipped with a stirrer, 92.5 parts of styrene and 0.46 parts of benzoyl peroxide are charged according to the mass ratio, and 5 parts of organically modified sodium-based montmorillonite are added to the three-necked flask under nitrogen protection and stirring. Soil and 2.5 parts of iron are heated to 85°C to polymerize to a viscous flowable prepolymer, and then placed in an oven at 70°C for 24 hours to solidify into a polystyrene compound. It was then heated at 900° C. for 10 min under a nitrogen atmosphere with a flow rate of 200 ml / min. The resulting mixture containing multi-layer graphene is added with a mass concentrati...

Embodiment 2

[0036] After mixing sodium montmorillonite and cetyltrimethylammonium bromide at a mass ratio of 1:2, add it to distilled water at a liquid-solid mass ratio of 100ml / g, heat and stir at 80°C for 48h Centrifuge, wash with distilled water until neutral, and dry to obtain organically modified sodium-based montmorillonite.

[0037] In a three-necked flask equipped with a stirrer, load 92.5 parts of styrene and 4.925 parts of benzoyl peroxide according to the mass ratio, and add 5 parts of organically modified sodium-based montmorillonite to the flask under nitrogen protection and stirring And 2.5 parts of copper, the temperature is raised to 85 ° C to polymerize to a viscous flowable prepolymer, and then put into an oven at 80 ° C for 12 hours to solidify into a polystyrene compound. It was then heated at 1000° C. for 15 minutes under a nitrogen atmosphere with a flow rate of 100 ml / min. The obtained mixture containing multi-layer graphene is added with a mass concentration of 30...

Embodiment 3

[0040] Ferric chloride, sodium silicate and zinc acetate were formulated into a solution at a molar ratio of 1.4:3.8:0.25, adjusted to pH 12.5, and placed in an autoclave at 140°C for 72 hours to obtain iron-based montmorillonite. After mixing the above-mentioned iron-based montmorillonite and octadecyldimethylbenzyl ammonium bromide in a ratio of 1:0.5 by mass ratio, it was added to distilled water at a liquid-solid mass ratio of 80ml / g at 120 After heating and stirring at ℃ for 4 hours, centrifuge, wash with distilled water until neutral, and obtain organically modified iron-based montmorillonite after drying.

[0041] In a three-necked flask equipped with a stirrer, 88 parts of methyl methacrylate and 0.264 parts of benzoyl peroxide are charged according to the mass ratio, and 8 parts of organically modified iron are added to the flask under nitrogen protection and stirring. Based on montmorillonite and 4 parts of copper, the temperature is raised to 80°C for polymerization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com