Method for crosslinking modification of microfiber collagen by multistep continuous enzyme catalysismicrofibril

A collagen cross-linking and microfiber technology, applied in chemical instruments and methods, animal/human proteins, connective tissue peptides, etc., can solve problems such as research blanks, achieve improved mechanical properties, heat-resistant stability, and cross-linking uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

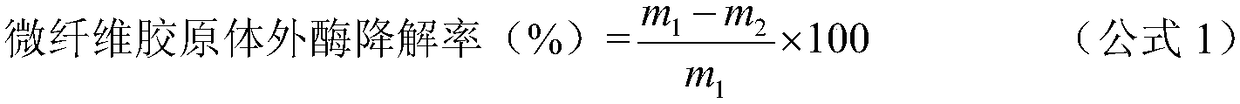

[0053] The selected microfibril collagen raw material is a common product made according to existing literature. The content of short fibers (fiber length≤1mm) in the microfibrous collagen is 36.3%.

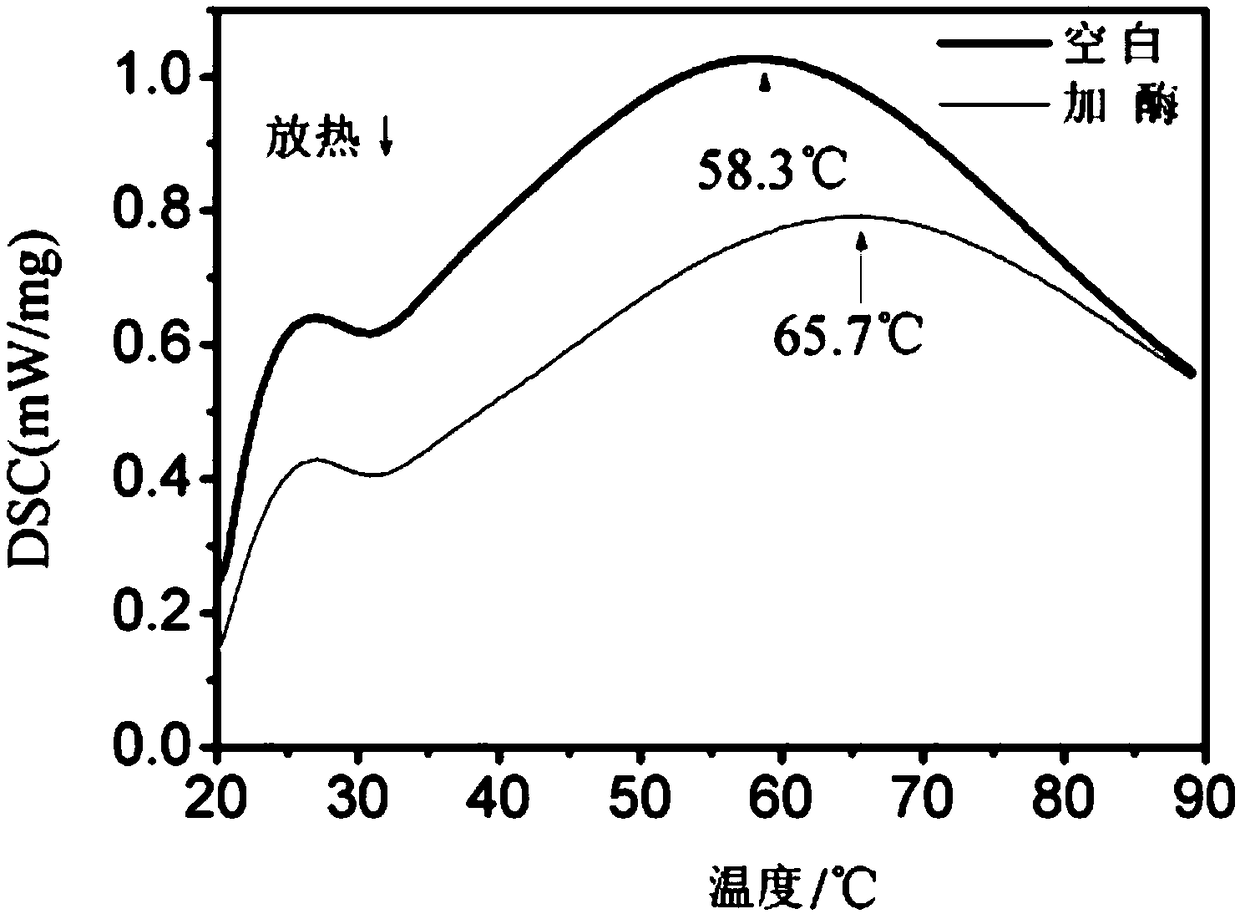

[0054] Add 2000g of microfibrous collagen raw materials into deionized water to prepare a mixed solution with a solid content of 2.5%. Fully disperse the microfibrous collagen raw materials evenly by shaking, and no precipitation will occur after standing for 15 minutes. Adjust the pH of the mixed solution to 6.0~ 7.0; then 50g of transglutaminase (specific activity: 100U / g) weighed at 2.5U / g by the dry weight of microfibril collagen was added to the mixed solution and catalyzed for 2.5h at 28°C; the catalytic reaction time reached Finally, the pH of the mixed solution was adjusted to be 5.0 to 5.5, and then 1 g of tyrosinase (specific activity of 500 U / mg) weighed at 250 U / g in terms of the dry weight of microfibril collagen was added to the mixed solution, and the following Th...

Embodiment 2

[0057] The selected microfibril collagen raw material is a common product made according to existing literature. The content of short fibers (fiber length≤1mm) in the microfibrous collagen is 27.2%.

[0058] Add 700g of microfibrous collagen raw materials into deionized water to prepare a mixed solution with a solid content of 2.5%. Fully disperse the microfibrous collagen raw materials evenly by shaking, and no precipitation will occur after standing for 15 minutes. Adjust the pH of the mixed solution to 6.0~ 7.0; Then 14g of transglutaminase (specific activity is 100U / g) weighed in microfibril collagen dry weight 2.0U / g was added to the mixed solution, and 0.1% and mol Concentration of 1mol / L CaCl 2 Catalyze the reaction for 3h at 28°C; after the catalytic reaction time is reached, adjust the pH of the mixed solution to be 6.5 to 7.0, and then take the horseradish peroxidase 1.09g (specifically Activity is 160U / mg) was added to the mixture and continued to catalyze the rea...

Embodiment 3

[0061] The selected microfibril collagen raw material is a common product made according to existing literature. The content of short fibers (fiber length≤1mm) in the microfibrous collagen is 58.6%.

[0062] Add 3200g of microfibrous collagen raw materials into deionized water to prepare a mixed solution with a solid content of 2.5%. Fully disperse the microfibrous collagen raw materials evenly by shaking, and no precipitation will occur after standing for 20 minutes. Adjust the pH of the mixed solution to 6.0~ 7.0; then the transglutaminase 32g (specific activity is 100U / g) weighed by microfibril collagen dry weight 1.0U / g is added in the mixed solution, and 0.1% and mol Concentration of 0.5mol / L CaCl 2 The solution was catalyzed for 2 hours at 25°C; after the catalyzed reaction time was up, the pH of the mixed solution was adjusted to be 5.0 to 5.5, and then 1.28g of tyrosinase (specific activity 500U / mg) was added to the mixed solution to continue the catalytic reaction a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat denaturation temperature | aaaaa | aaaaa |

| Specific vitality | aaaaa | aaaaa |

| Heat denaturation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com