Trough type steel rail resistant to concrete corrosion and production method of trough type steel rail

A technology of grooved steel rail and concrete, which is applied in the direction of track, track superstructure, manufacturing converter, etc., to meet the requirements of service performance and corrosion resistance, improve the corrosion resistance of concrete, and reduce the cost of alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

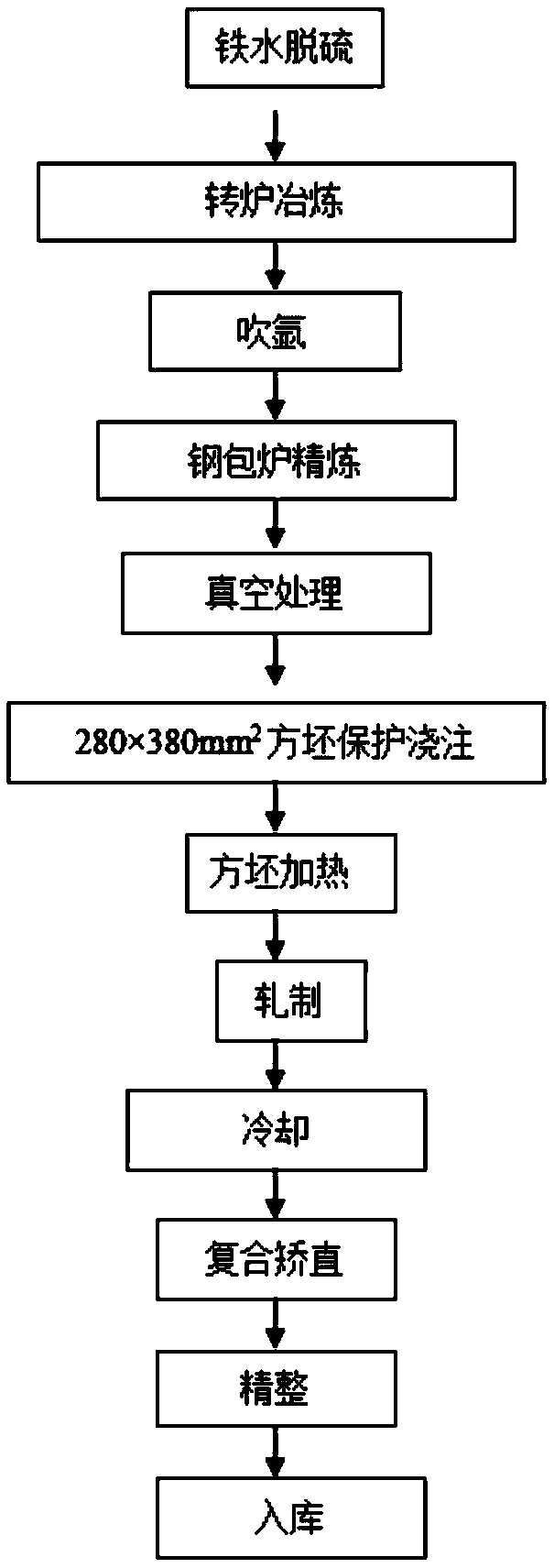

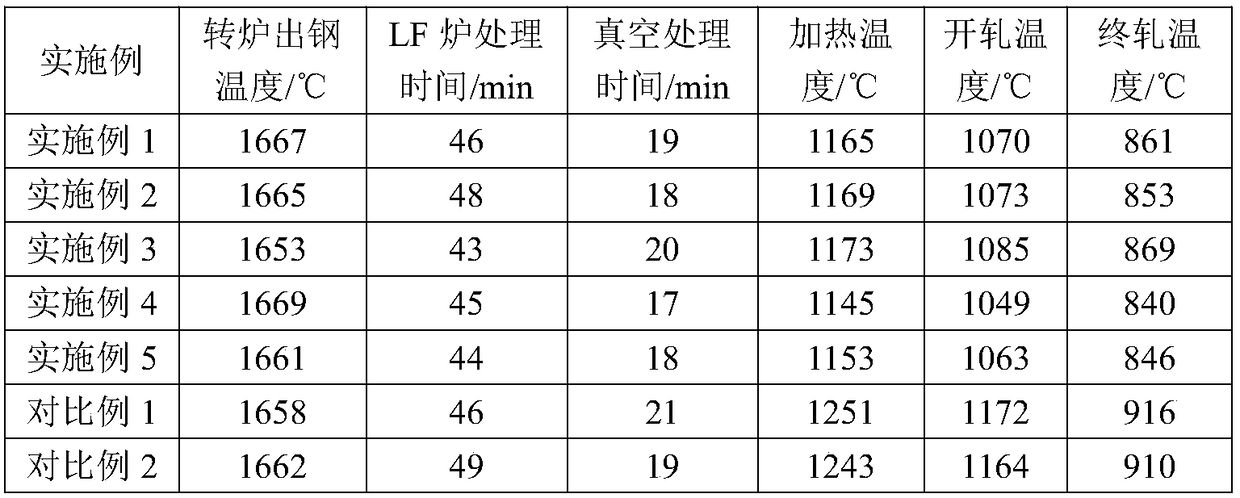

[0032] The schematic diagram of the production process of the concrete corrosion-resistant hot-rolled channel rail described in embodiments 1 to 5 is shown in figure 1 , the specific preparation method includes the following steps: desulfurization of molten iron, 120-ton converter smelting, argon blowing, ladle furnace refining, vacuum treatment, continuous casting, heating, rolling, and the parameters of the main steps are:

[0033] Converter smelting: slag basicity is controlled at 2.5-4.5, tapping temperature control target: 1660±15°C, when tapping molten steel is about 1 / 4, deoxidizing alloys such as silicon and manganese and recarburizers are added along with the steel flow, and the molten steel is tapped to 3 / 4, all alloys and carburizers are added;

[0034] Ladle furnace refining: white slag operation is adopted, the slag basicity is controlled at 2-4, and the chemical composition is adjusted according to the target composition after forming white slag; LF furnace proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com