Pyrolysis device for organic matter in crushed materials after crushing of waste lithium ion batteries

A lithium-ion battery and organic matter technology, which is applied in the field of waste battery recycling and processing equipment, can solve problems such as high cost, no recycling value, and difficult electrolyte recycling, and achieve the effects of improving environmental protection, improving quality, and improving pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

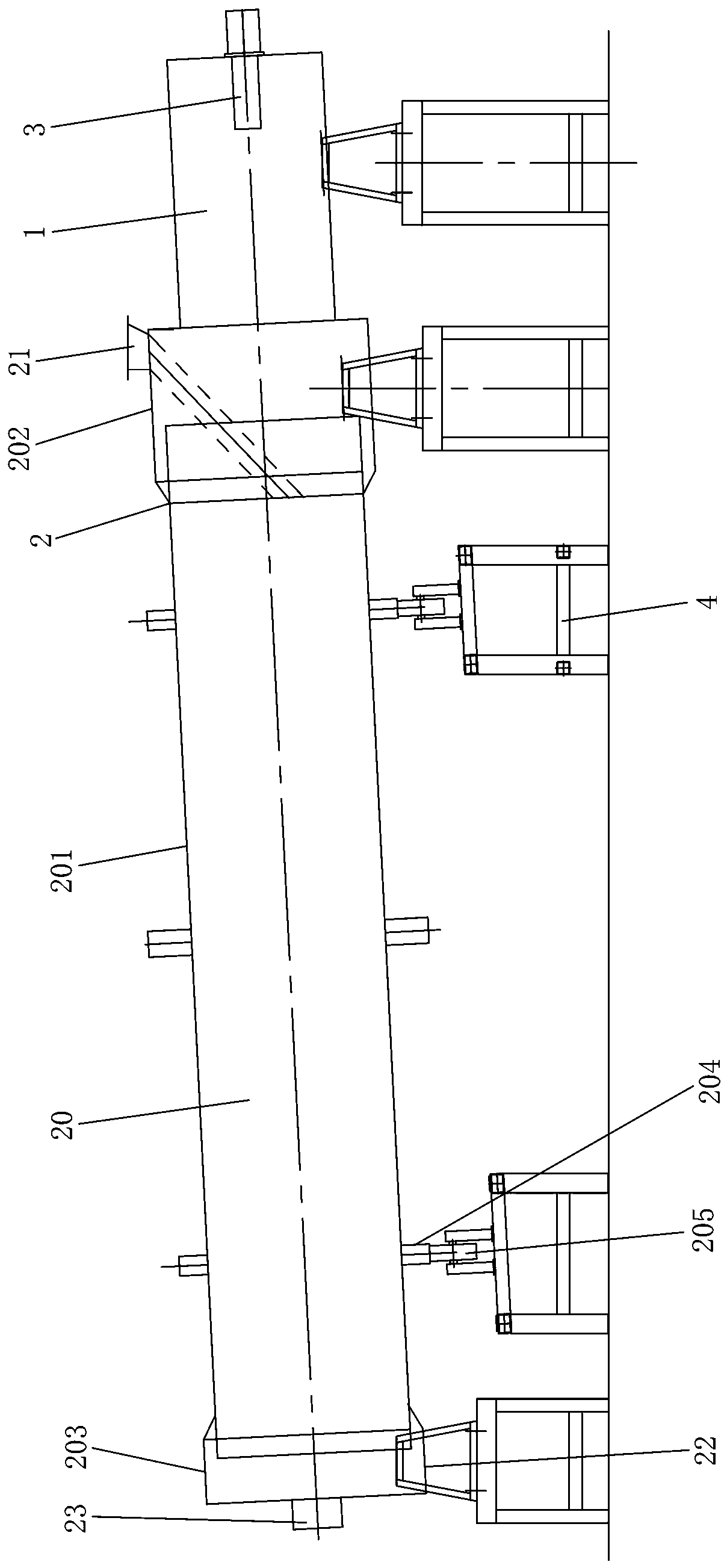

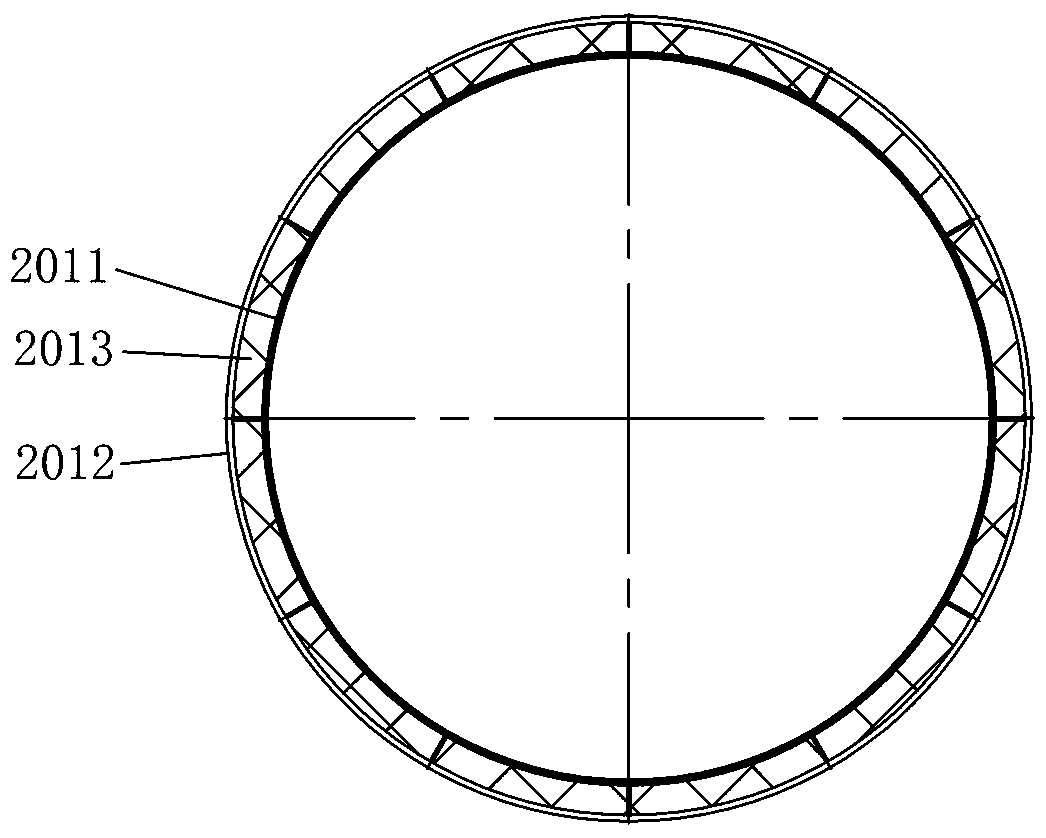

[0022] Such as figure 1 and figure 2 As shown, the pyrolysis equipment for the organic matter in the broken materials of the waste lithium-ion battery of this embodiment includes a combustion chamber 1 and a furnace body 2 with a furnace 20, and the furnace 20 is provided with a feed port 21, a discharge port 22 and a smoke Gas outlet 23, the combustion chamber 1 is connected with a combustion assembly 3 for generating hot atmosphere in the combustion chamber 1, and the furnace 20 communicates with the combustion chamber 1. When the pyrolysis equipment is working, the crushed waste lithium ion battery is fed into the furnace 20 from the feed port 21, and the combustion assembly 3 is used to generate a hot atmosphere in the combustion chamber 1, and the hot atmosphere will enter the furnace 20 and contact with the scrap In this way,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com